General glass fiber vitrolite and its industrial production method

A technology of industrial scale and manufacturing method, applied in the whole body glass chemical fiber porcelain plate and its industrial scale manufacturing field, can solve the problems of poor beautification and decoration performance, easy to be polluted, difficult to clean, etc., to achieve rich three-dimensional levels, not easy to be polluted, Easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

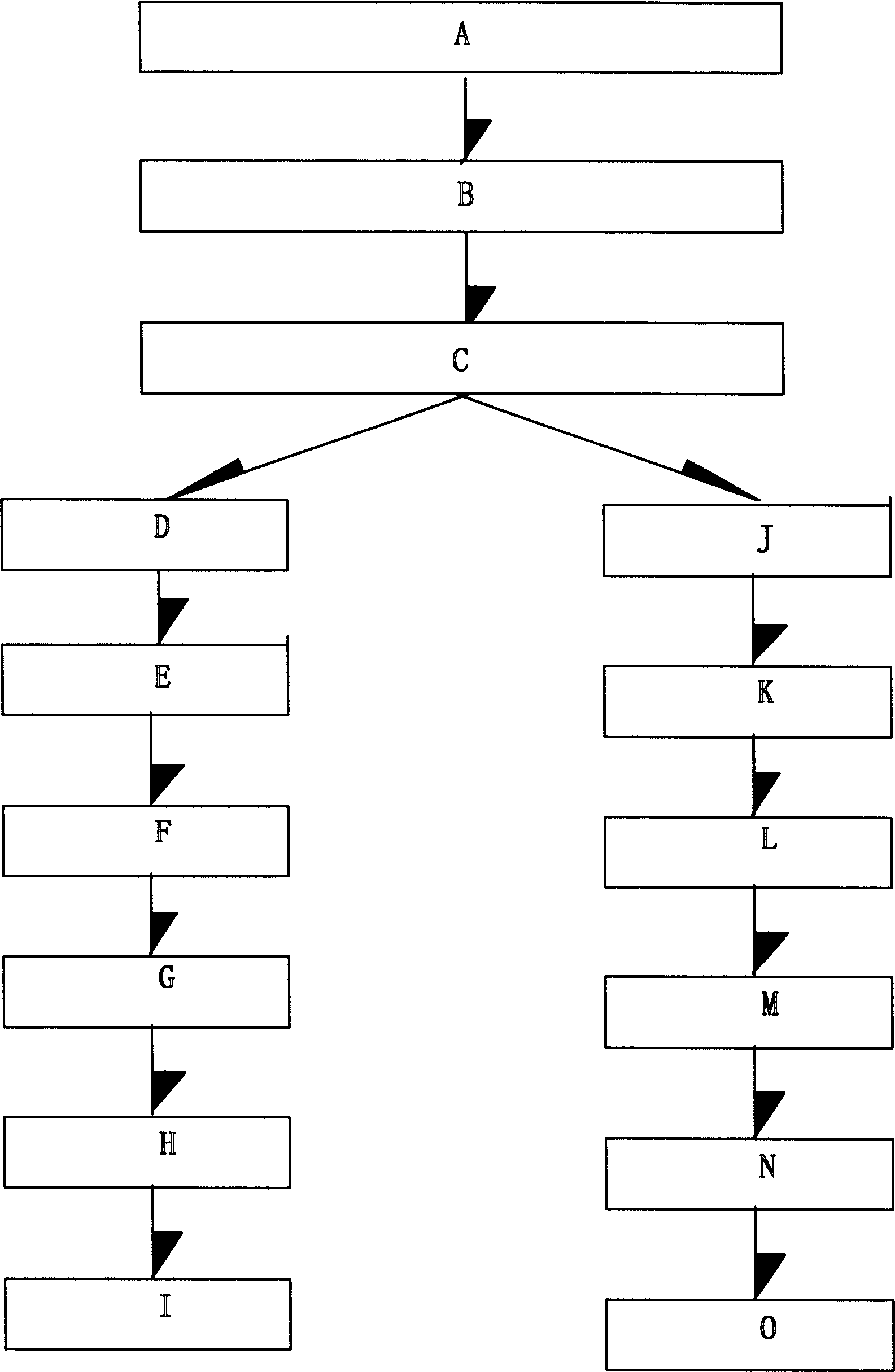

Method used

Image

Examples

Embodiment 1

[0038] (1) Ingredients

[0039] Raw material weight component: (kg)

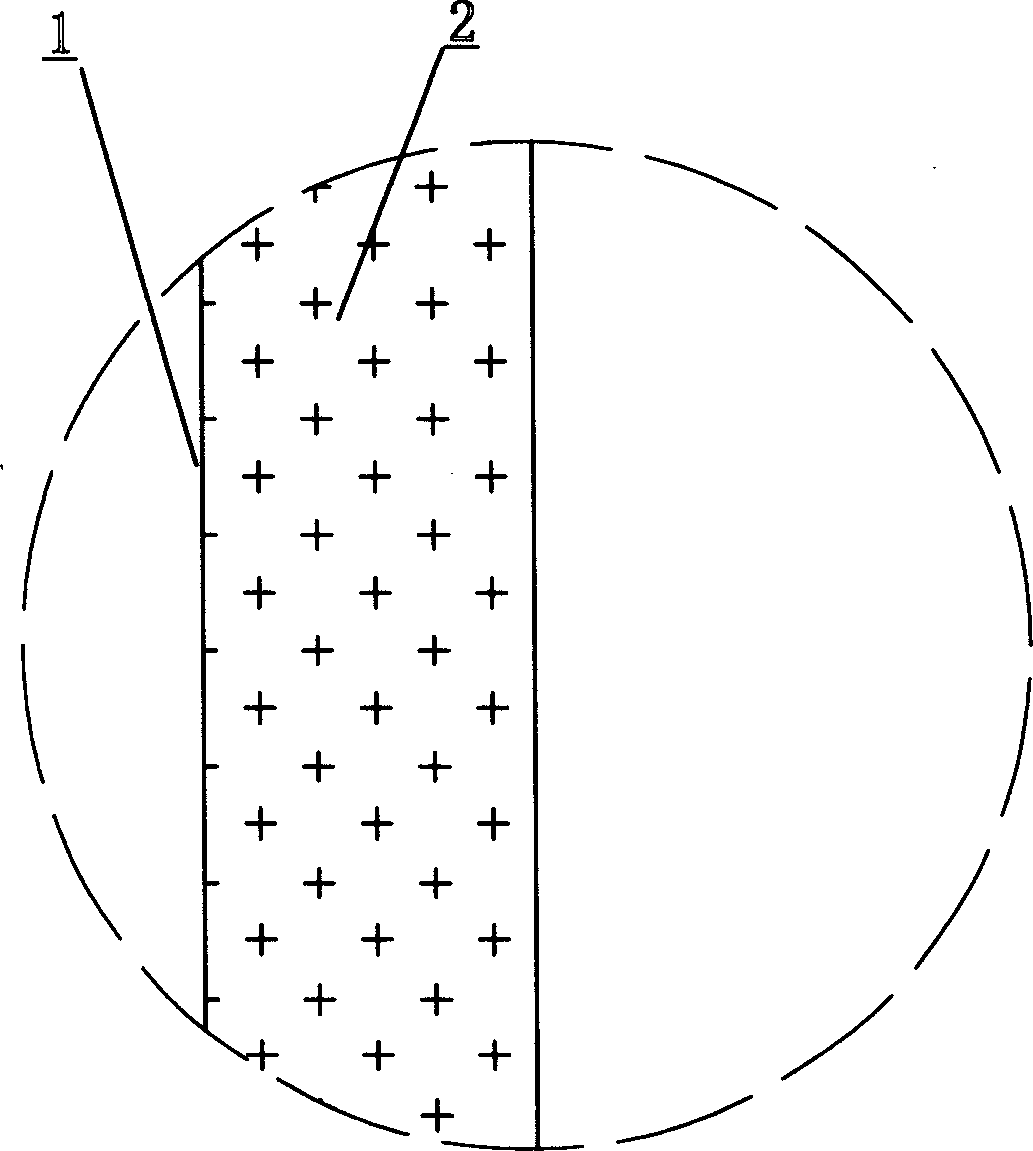

[0040] 60 parts of clay, 3 parts of mullite, 40 parts of china clay, 10 parts of wollastonite, 30 parts of feldspar, 23 parts of bentonite, 2 parts of inorganic pigments; the aspect ratio of raw wollastonite fiber is length: width =1:16.5.

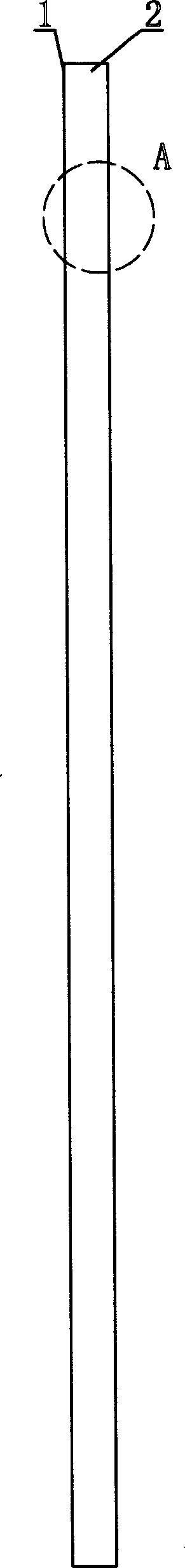

[0041] (2) Crushing, forming, drying and sintering of the green body

[0042] Weigh each raw material component according to the proportion, except for wollastonite, the other main materials and additives are pulverized to a particle size of ≤200 mesh, and then wollastonite is added; the raw materials and additives are fully mixed, water is added, and the water content is 15~ 20% of the mud; the mud is extruded by the forming machine into a continuous blank output; after multi-stage rolling and cutting, it becomes a green body of length×width×thickness=3550mm×1050mm×3mm; the green body is 200~ 300℃, dry for 0.5~1h;

[0043] After the dried green body is cut, it is eutectic s...

Embodiment 2

[0052] (1) Ingredients

[0053] Raw material weight component: (kg)

[0054] 10 parts of clay, 30 parts of mullite, 5 parts of china clay, 60 parts of wollastonite, 5 parts of feldspar, 40 parts of bentonite, 30 parts of inorganic pigments; the aspect ratio of raw wollastonite fiber is length: width =1:18.5.

[0055] (2) Crushing, forming, drying and sintering of the green body

[0056] Weigh each raw material component according to the proportion, except for wollastonite, the other main materials and additives are crushed to a particle size of ≤200 mesh before adding

[0057] Put the wollastonite; mix the raw materials and additives thoroughly, add water, and mix into a mud with a water content of 15-20%; the mud is extruded by a forming machine into a continuous blank output; after multi-stage rolling and cutting, it becomes a long ×width×thickness=2050mm×2080mm×6mm green body; after surface embossing and cutting, the green body is dried at 100~200℃ for 2~3h, and then eutectic s...

Embodiment 3

[0060] (1) Ingredients

[0061] Raw material weight component: (kg)

[0062] 30 parts of clay, 20 parts of mullite, 20 parts of china clay, 50 parts of wollastonite, 15 parts of feldspar, 30 parts of bentonite, 20 parts of inorganic pigment for blank; the aspect ratio of raw wollastonite fiber is length: width =1:19.5.

[0063] (2) Crushing, forming, drying and sintering of the green body

[0064] Weigh each raw material component according to the proportion, except for wollastonite, the other main materials and additives are crushed to a particle size of ≤200 mesh before adding

[0065] Put the wollastonite; mix the raw materials and additives thoroughly, add water, and mix into a mud with a water content of 15-20%; the mud is extruded by a forming machine into a continuous blank output; after multi-stage rolling and cutting, it becomes a long ×width×thickness=3050mm×2080mm×4.5mm green body; the green body is dried at 100~200℃ for 2.5~3h;

[0066] After the dried green body is cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com