System for automatically measuring container capacity

A technology for automatic measurement and tank storage, which is applied in the direction of volume measurement instruments/methods, container/cavity capacity measurement, and measurement devices. It can solve problems such as poor accuracy, slow measurement speed, and measurement results affected by human factors. The effect of reducing error, improving measurement accuracy, and fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

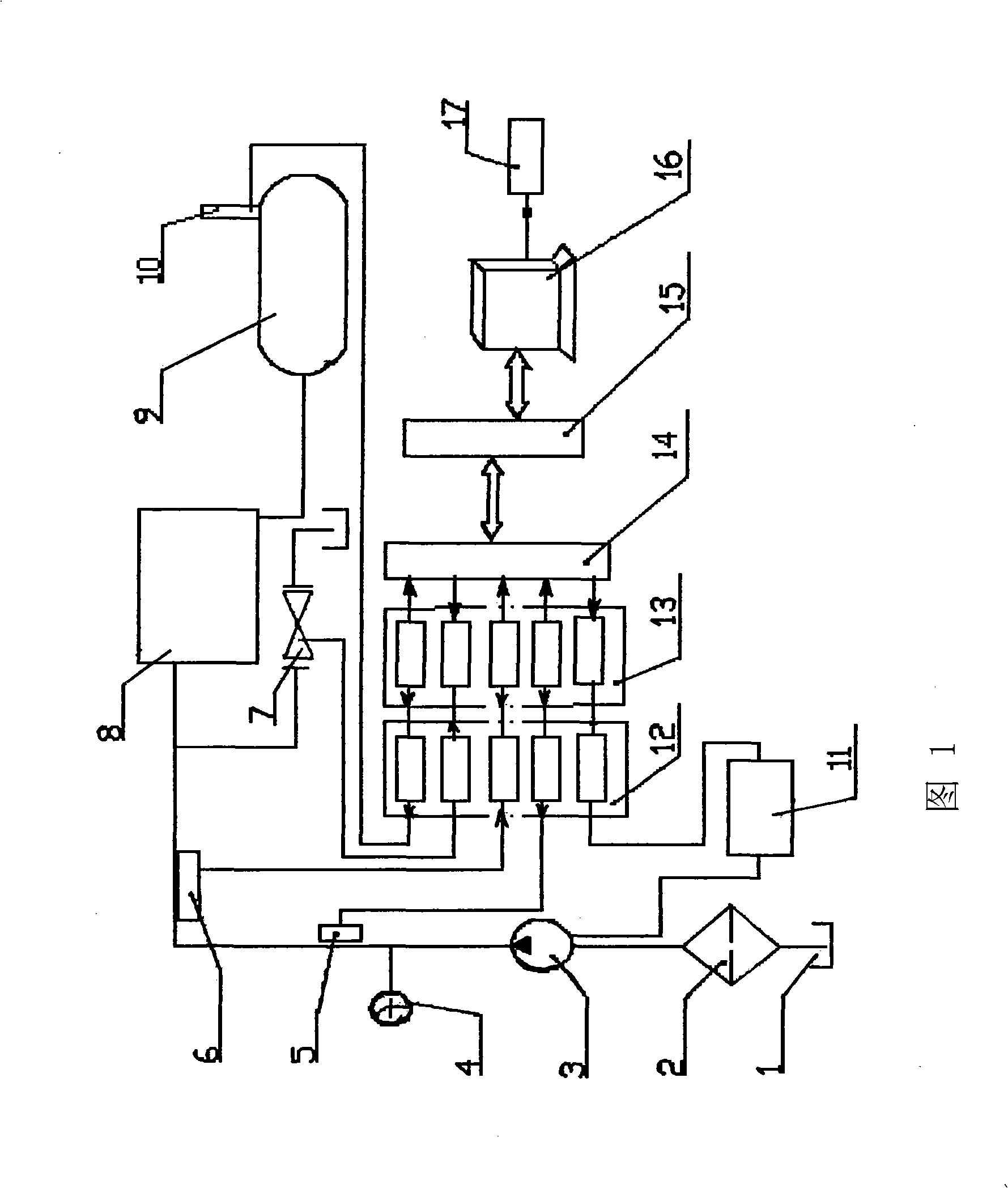

[0008] As shown in Figure 1, the present invention is a kind of storage tank volume automatic measuring system, has a water tank 1, connects with measuring water tank 8 through a pipeline, is equipped with a filter 2, a centrifugal pump 3, a The standard flow meter 4 and the centrifugal pump 3 adjust their rotating speed through the frequency converter 11. The frequency converter 11 inputs the flow rate signal of the test liquid flowing through the centrifugal pump 3 into the operational amplifier 12. A pressure sensor 5 and a temperature sensor 5 are respectively installed on the above-mentioned pipelines. The sensor 6, the pressure sensor 5 and the temperature sensor 6 respectively input the pressure and temperature information of the test liquid into the operational amplifier 12, an electromagnetic reversing valve 7 and a measuring water tank 8 are connected in parallel with the above-mentioned pipeline, and the measuring water tank 8 is connected to the measured storage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com