Working method of lambda seeker

A detector, working technology, applied in the field of lambda detectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

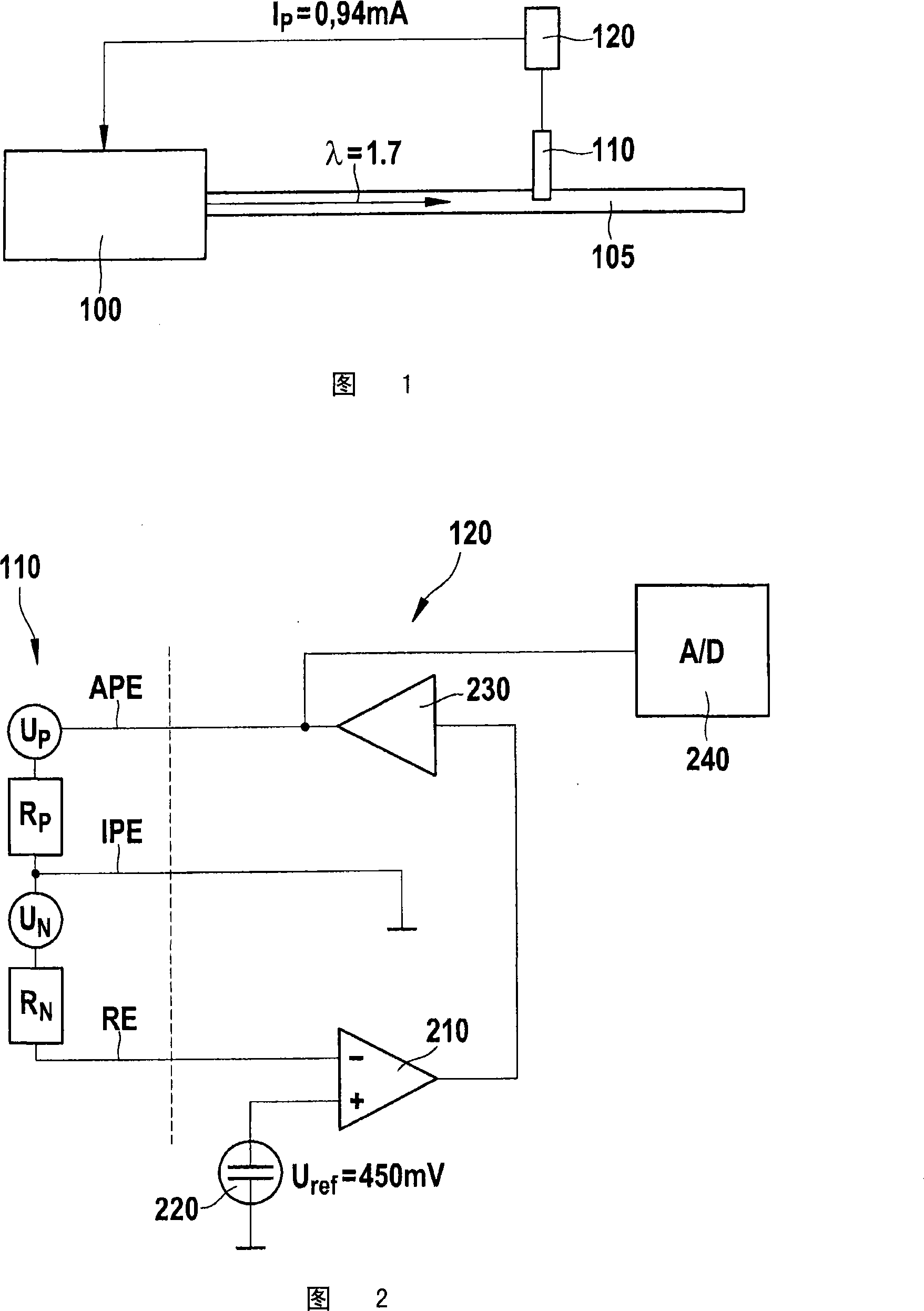

[0026] FIG. 1 shows a schematic diagram of a control system for parameters characterizing the injection process of an internal combustion engine.

[0027] A lambda sensor 110 is arranged in the exhaust tract 105 of the internal combustion engine 100 , the output signal of which is processed in an electronic control unit 120 , in particular an engine control unit.

[0028] For example, at a λ value of λ=1.7 to be adjusted, the electronic control unit 120 predetermines a predeterminable pump current I of, for example, 0.94 mA by means of a characteristic curve stored in a software. P As an adjustment theoretical value for engine fuel injection.

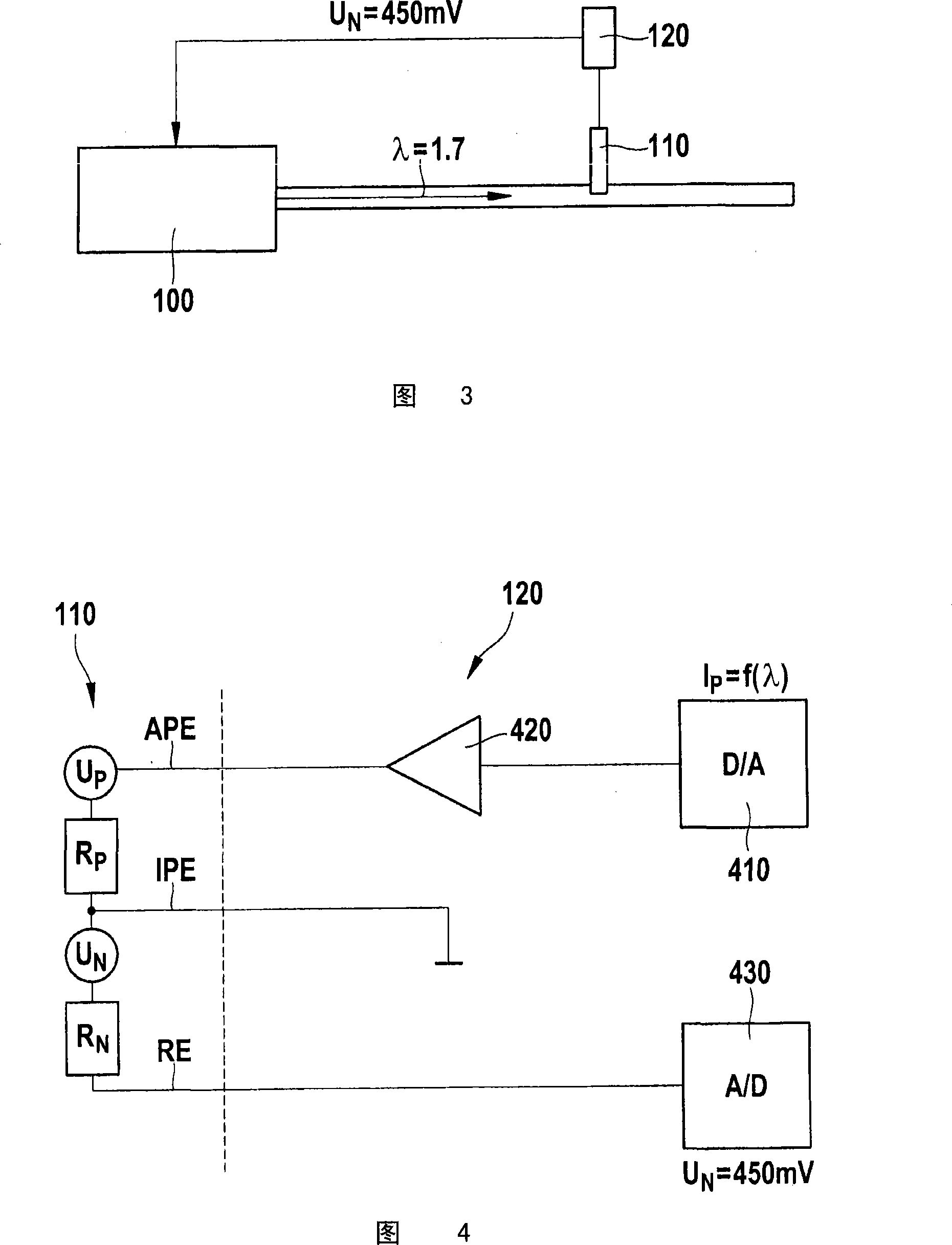

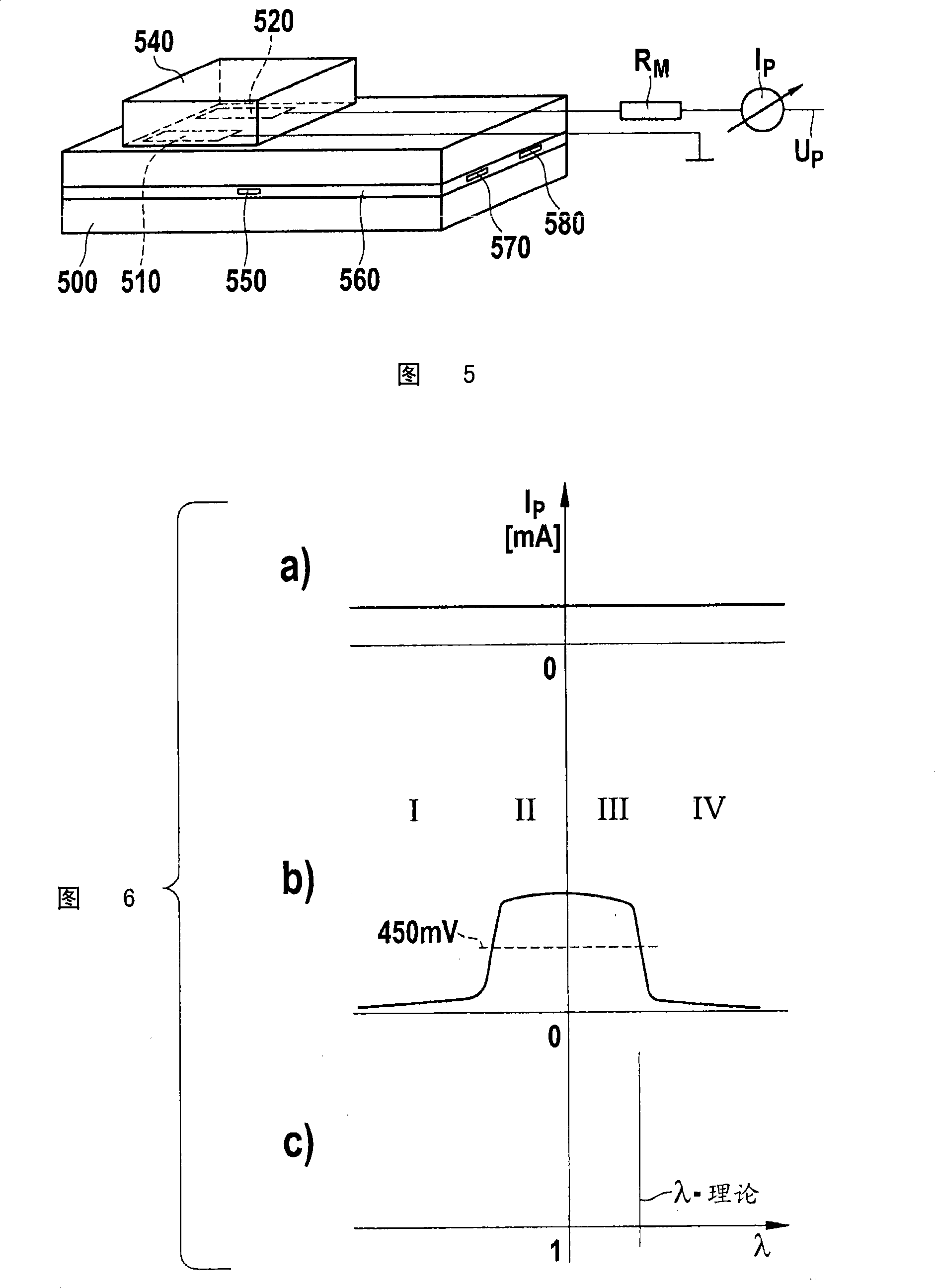

[0029] The lambda probe 110 shown in FIG. 2 consisting of a double cell has an outer pump electrode APE, an inner pump electrode IPE and a reference electrode RE. There is a pump voltage U between the outer pump electrode APE and the inner pump electrode IPE P , there is a Nernst voltage U between the internal pump electrode IPE, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com