Bionic drag reduction stubbling knife and design method thereof

A design method and stubble cutting knife technology, which can be applied to tillage machines, crop processors, cutters, etc., can solve the problems of high cutting resistance and high energy consumption, and achieve the effects of reducing traction resistance, improving efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

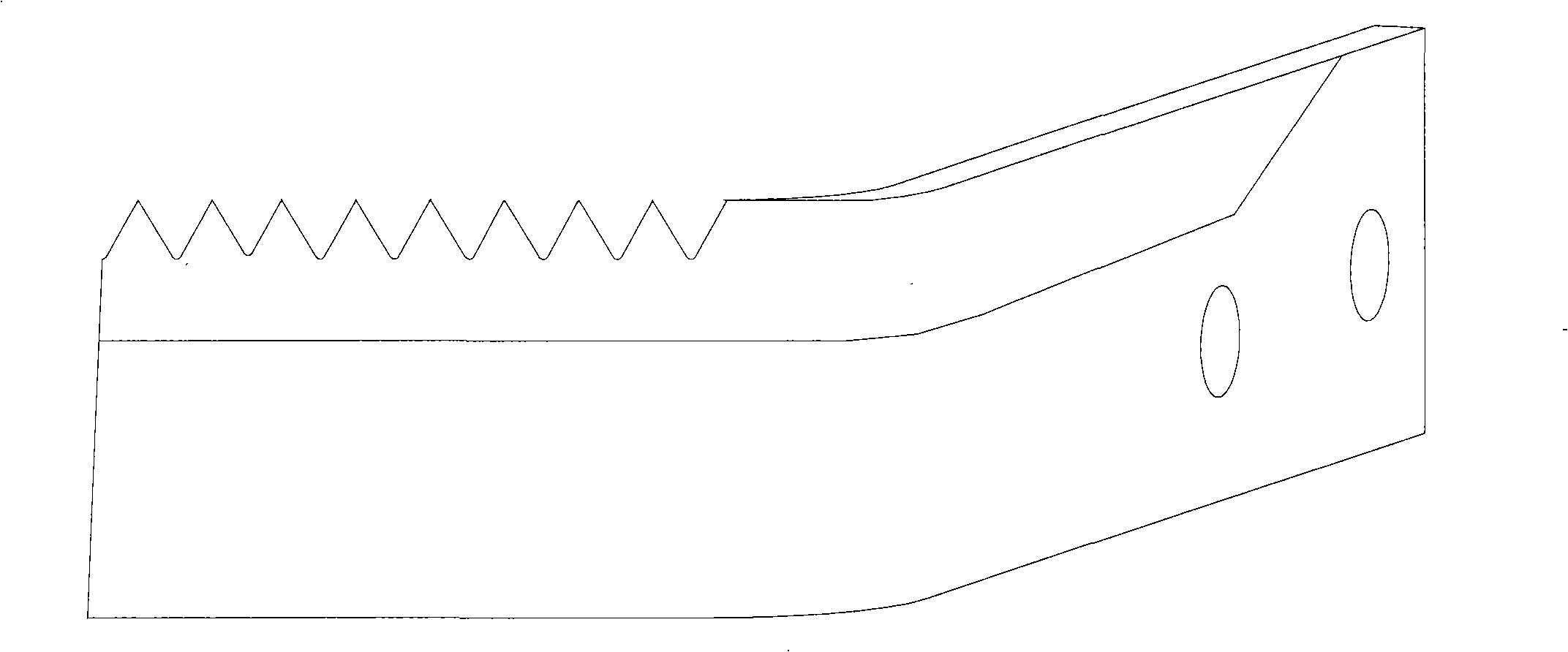

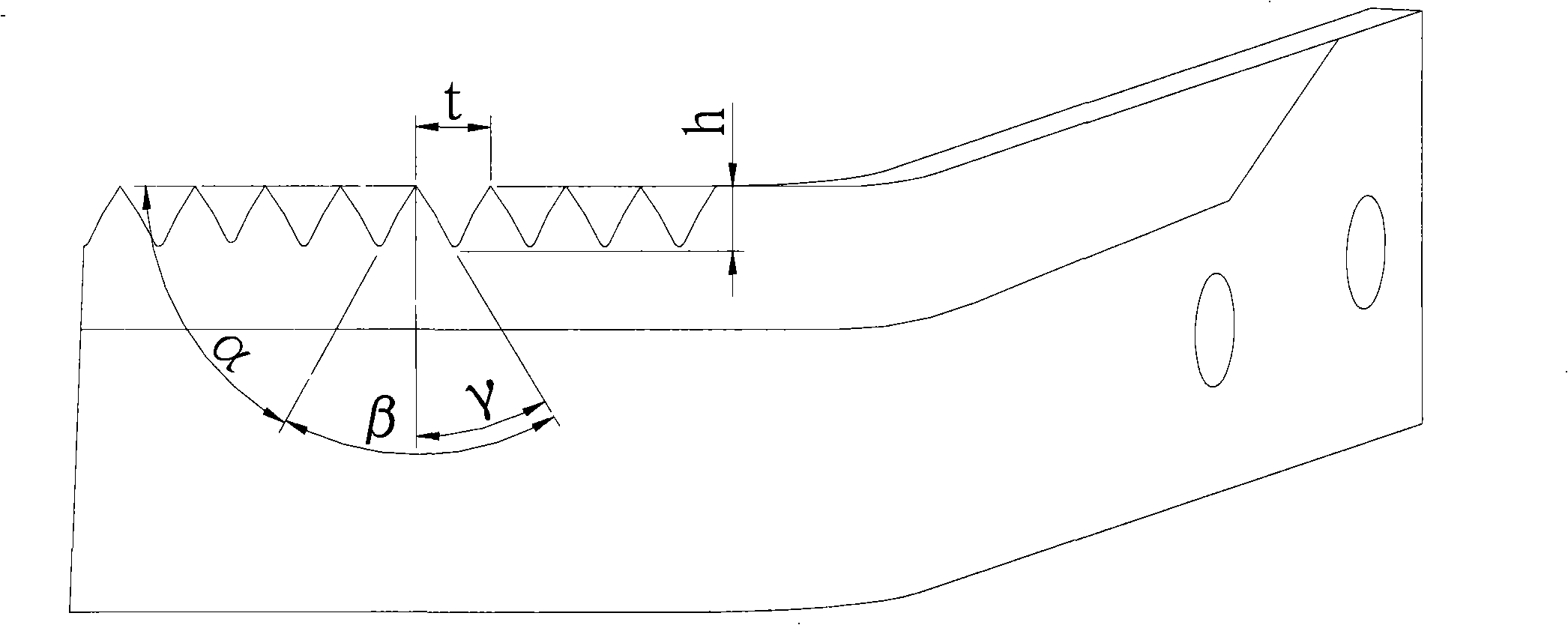

[0024] 1. Use a stereo microscope to take pictures of the excavated and cut claws of mole crickets, and extract the surface features. It can be observed that the claws and toes have serrations.

[0025] 2. Fit the data of the sawtooth on the claw toe to get the sawtooth curve of the claw toe.

[0026] The curve equation is: 0.0185x 4 -0.5897x 3 +5.1837x 2 -6.7286x+5.9365

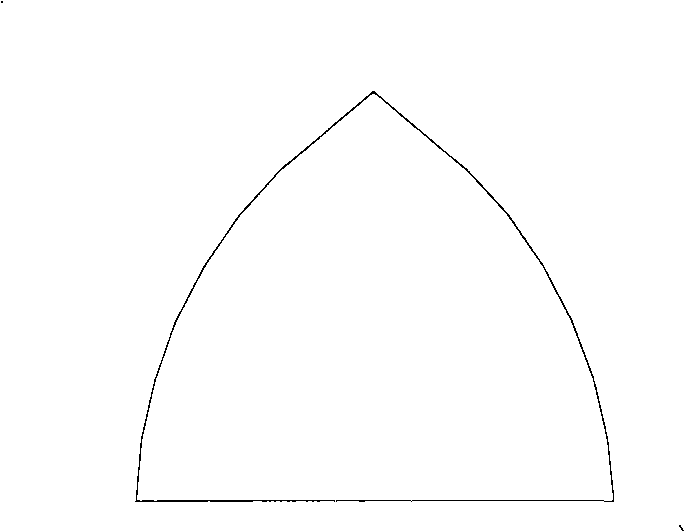

[0027] 3. The serrated teeth are processed on the main edge of the commonly used L-shaped stubble cutter, the tooth pitch t=6mm, the tooth height h=4mm, that is, h / t=2 / 3, the tooth throat angle γ=0°, the tooth tip angle β= 50°, then the back angle α=40°. The two sides of the sawtooth are fitted with the above curves, and the R1 arc transition at the tooth root part, refer to the enlarged picture of the sawtooth image 3 shown.

[0028] 4. Use the processing method of wire spark cutting to process, add the above-mentioned graphic programming into the computer console, and then process and obtain a new t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com