High pressure water mist foam extinguishing agent

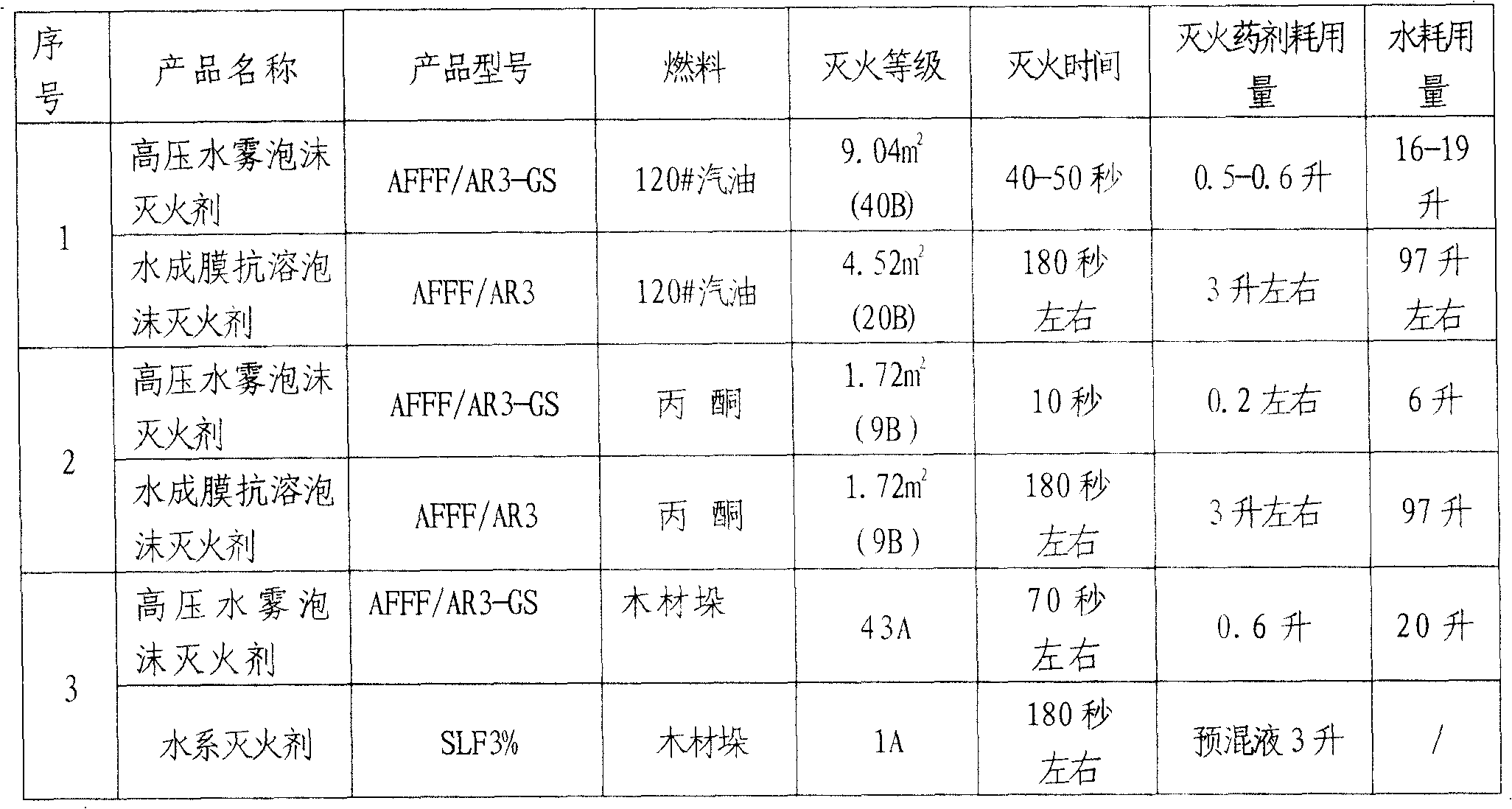

A foam fire extinguishing agent and water mist technology, which is applied in fire prevention equipment and other directions, can solve the problem of not being able to spray fine water mist beads normally for fire fighting, high pressure water mist equipment not being able to spray foam normally to extinguish Class B fires, and unable to give full play to high pressure water mist spraying. The potential of the shower system can be solved to achieve the effect of high fire extinguishing efficiency, good fluidity and fast fire extinguishing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 37kg of foaming agent imidazoline, compound fluorosurfactant FC-4 and 1127 for 5kg, penetrant 4018 for 1kg, antifreeze agent ethylene glycol 10kg, stabilizer sodium alginate 5kg, corrosion inhibitor benzotriazide 0.8 kg of azole and 41.2 kg of water are mixed, heated and stirred uniformly to obtain the product of the present invention.

Embodiment 2

[0028] Weigh 30 kg of foaming agent alkyl glucoside, 10 kg of compound fluorosurfactants 1127, 1157 and 1203, 3 kg of penetrant powder, 15 kg of antifreeze diethylene glycol butyl ether, 6 kg of stabilizer sodium alginate, and Etching agent benzotriazole 0.4kg and 35.6kg water are mixed, heated and stirred uniformly to obtain the product of the present invention.

Embodiment 3

[0030] Weigh 40kg of foaming agent CAB, compound fluorosurfactant 1127, 1157, 1203 and 4018, 7kg, penetrant diethylene glycol ether 4kg, antifreeze formamide 12kg, stabilizer xanthan gum 7kg, corrosion inhibitor benzo 1 kg of triazole and 29 kg of water are mixed, heated and stirred uniformly to obtain the product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com