Flat plate silicon nitride film PECVD deposition system

A silicon nitride film and deposition system technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem that the uniformity of the deposited sample film is not well controlled, and the overall temperature uniformity and material quality cannot be guaranteed. Great influence and other problems, to achieve the effect of improving temperature and its uniformity, simple structure, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

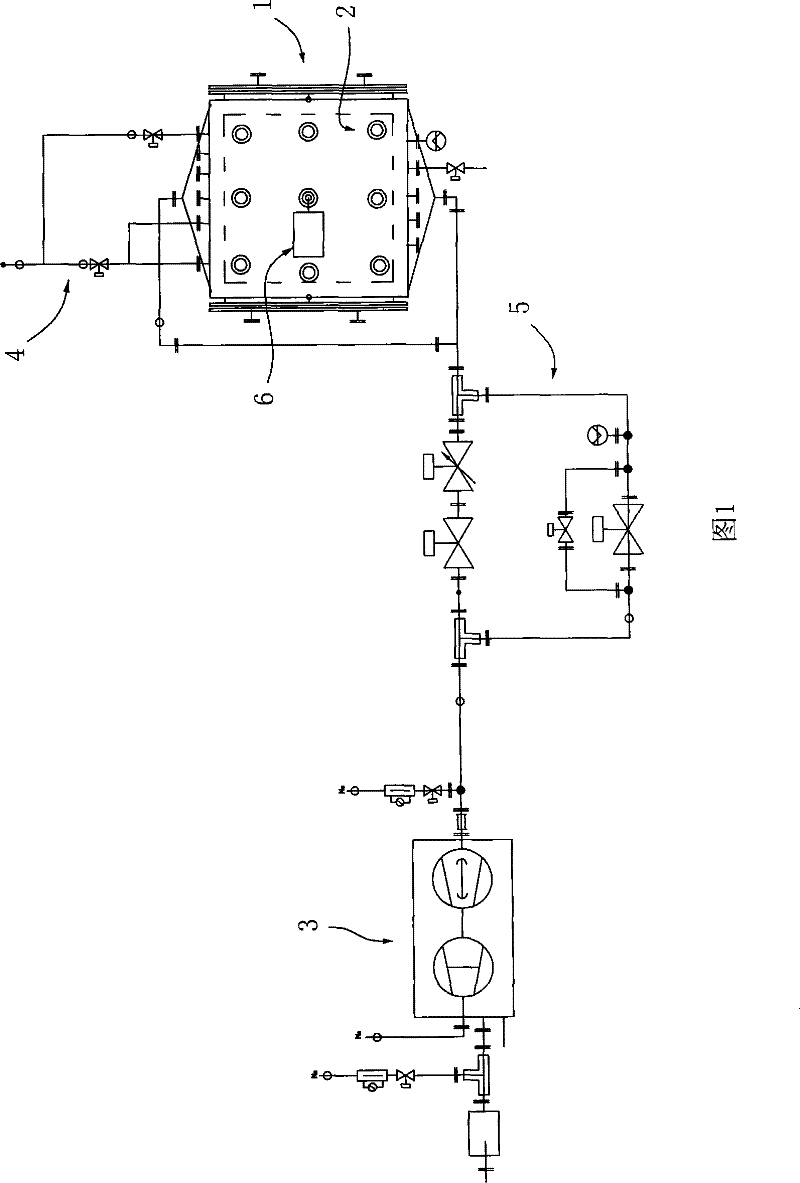

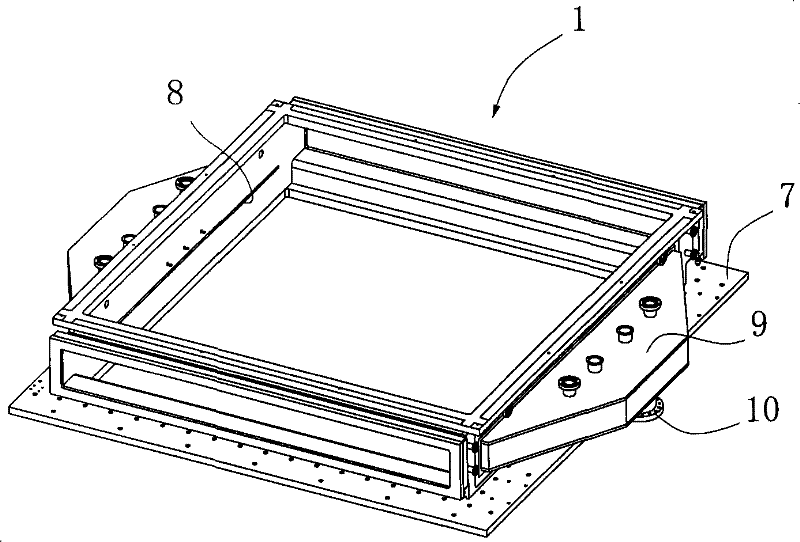

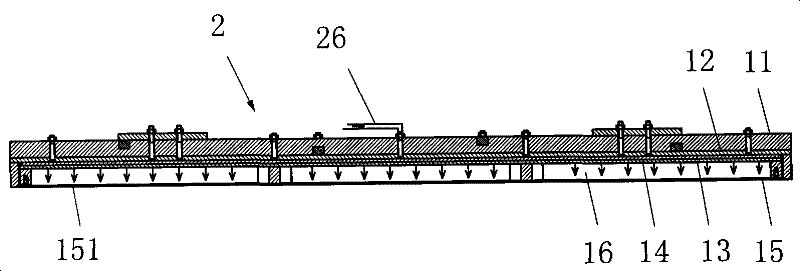

[0025] Example: such as figure 1 As shown, this flat silicon nitride thin film PECVD deposition system has the same parts as the existing ones, including a deposition chamber, electrodes, heater 7 and exhaust system 3, and the two sides of the deposition chamber are respectively connected with inlet pipes for reaction gas 4 and the exhaust pipe 5, the exhaust pipe 5 is connected with the exhaust system 3, and the radio frequency introduction electrode 2 is connected with the radio frequency power supply matching device 6; the difference from the prior art is that the deposition chamber is a flat vacuum chamber 1, and the electrode 2 is that the radio frequency introduction electrode 2 is arranged on the top of the vacuum cavity 1 ( figure 1 not shown), the heater 7 is located at the bottom of the vacuum chamber 1 . The following is a detailed description of each component:

[0026] Such as figure 2 As shown, the vacuum cavity 1 is a square shape, and the two sides are resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com