Tools-type barrel formwork and following platform whole set device

A barrel mold and tool technology, which is applied in the field of barrel molds and follow-up platforms, can solve the problems of easy up and down, and achieve the effects of light weight, smooth retractable and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

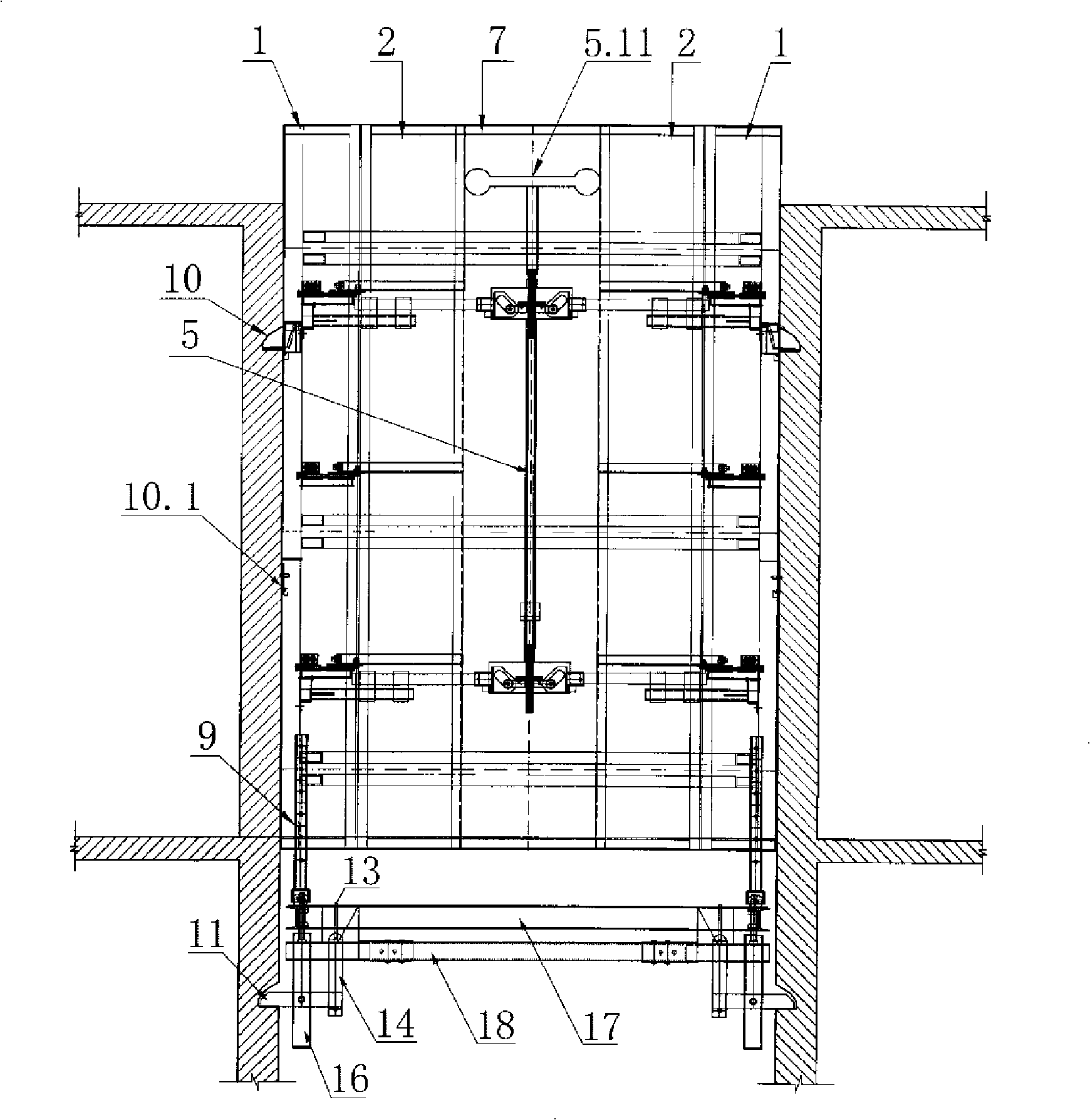

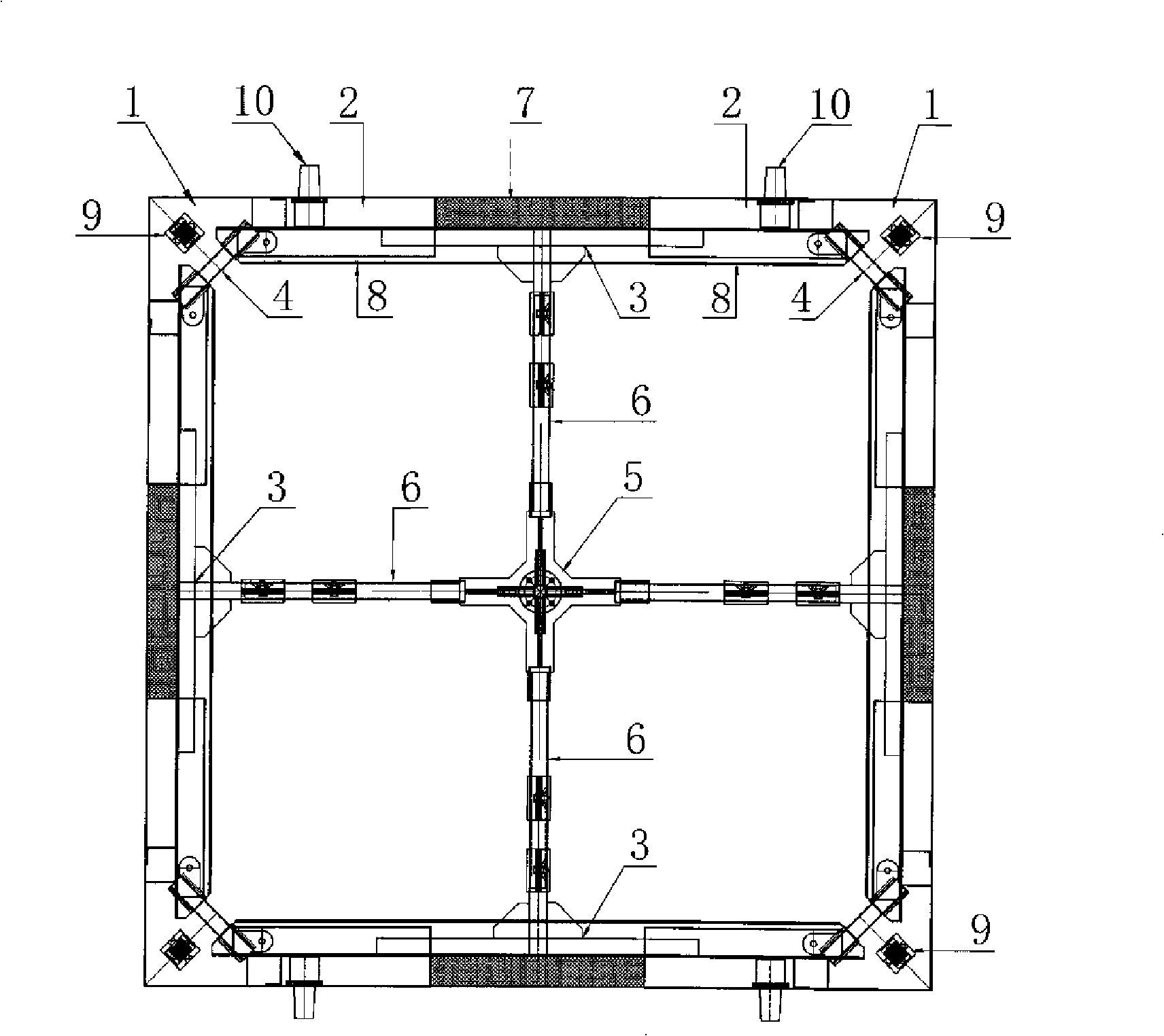

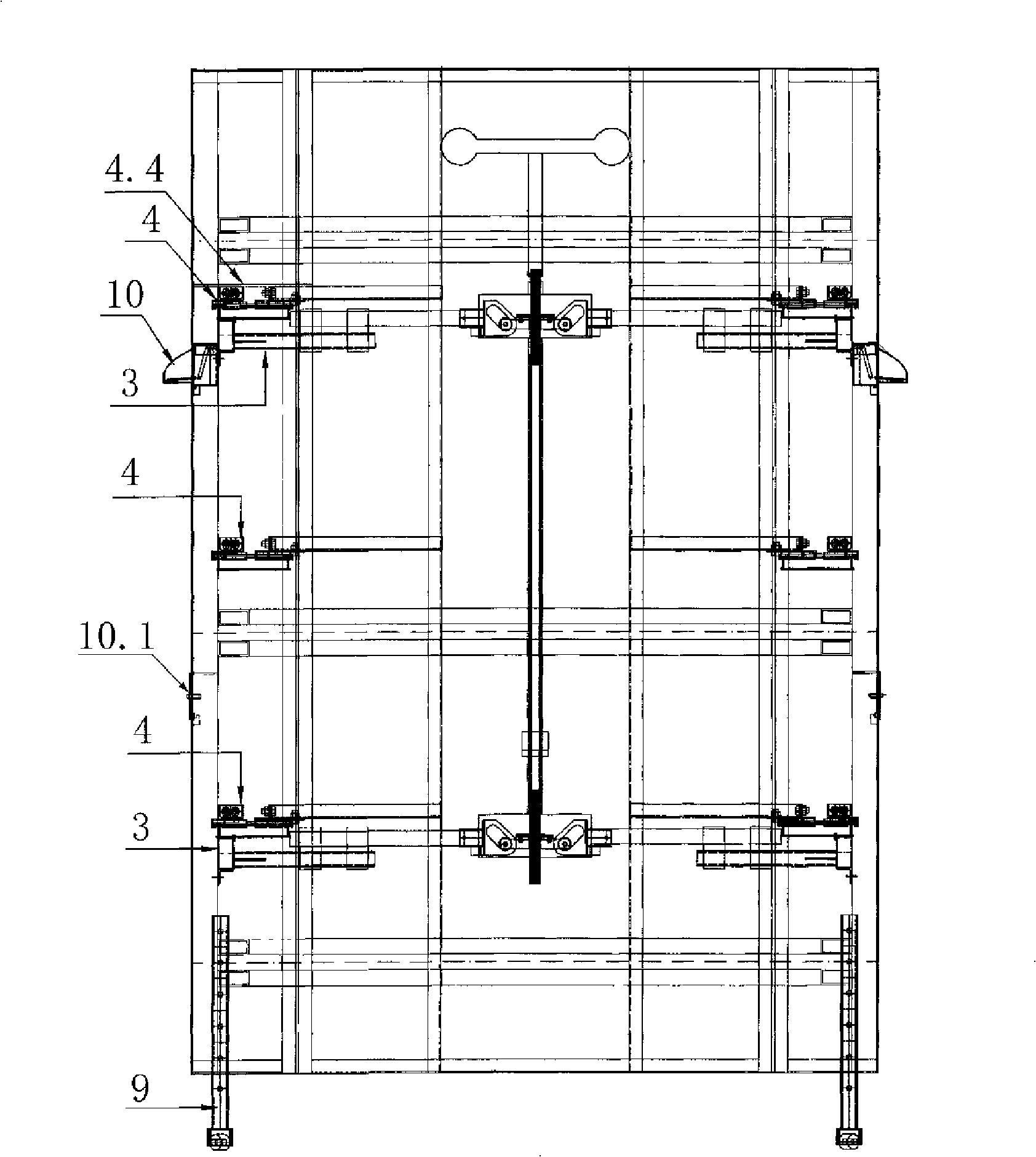

[0057] Examples see figure 1 , figure 2 , image 3 As shown, this tool-type cylinder mold is assembled into a cylinder with a rectangular cross-section by shaped parts, and four rigid angle molds 1 are placed on the four corners of the cylinder mold, and the two right angles of each rigid angle mold cylinder mold The surface is respectively connected with a shaping plate 2, the central retractable frame 5 of the cylinder mold is connected by two upper and lower retractable boxes 5.1 through the outer sleeve 5.6, the top of the push rod is connected with the handle 5.11, and the retractable box 5.1 passes through the slider 5.2 of the inner cavity It is connected with the horizontal push-pull rod 6, and connected with the four force transmission frames 3 through the horizontal push-pull rod 6, the outer end of the force transmission frame 3 is connected with the shaping plate, and the middle gap of each side wall of the cylinder mold is a replacement filling plate 7, The wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com