Filtering material for oil well sand preventing screen pipe and method for making same

A kind of sand control and effective technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of no dirt holding capacity, inability to suspend sand particles, unfavorable dirt holding, etc., and achieve high dirt holding capacity and uniform size. , the effect of uniform linear density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

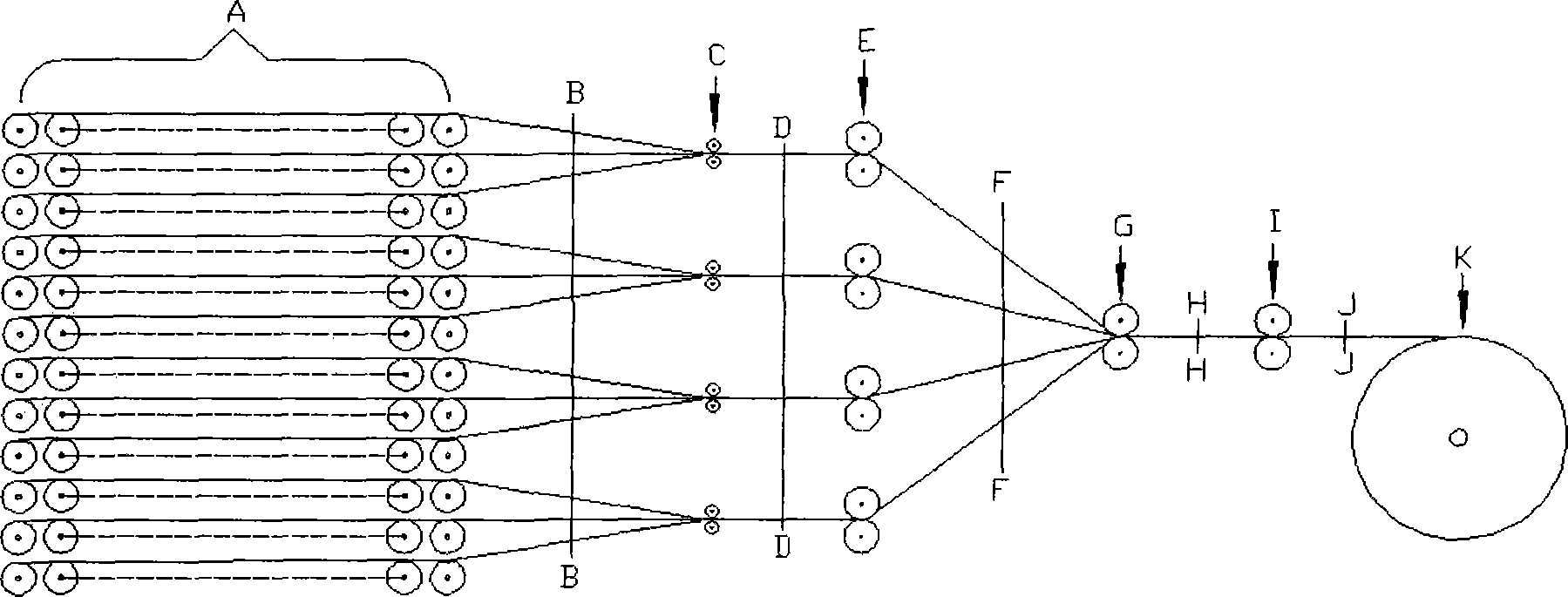

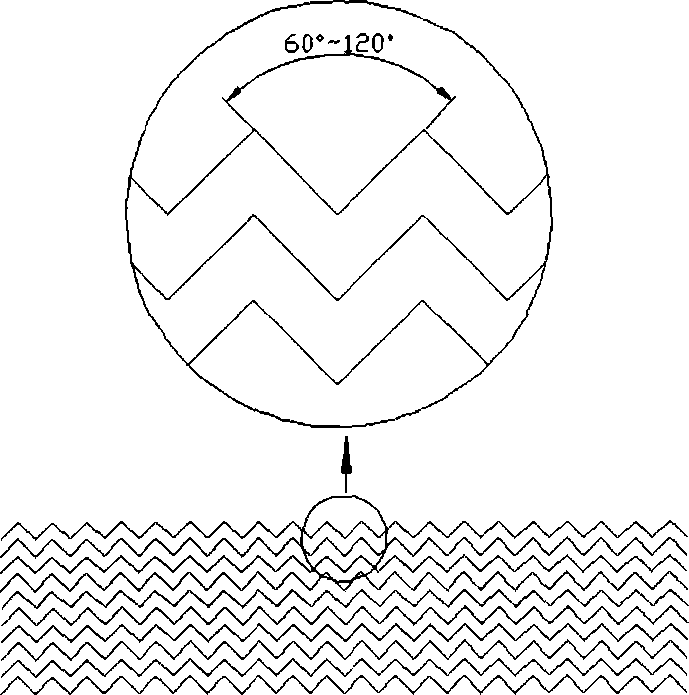

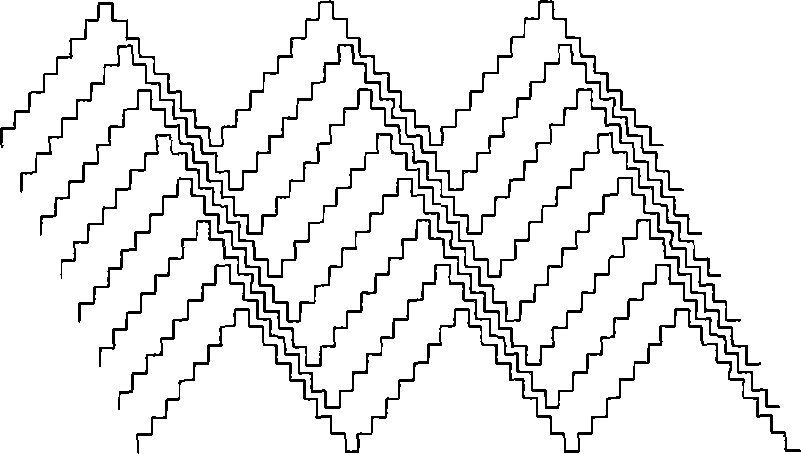

[0021] see figure 1 (Among them, A means wire rollers, usually 400-1200 pieces, depending on the demand; B-B means that the wires are roughly divided into 4 groups, and then sent to the guide roller C; E means the first stage pressure roller; G means The second stage pressure roller; I represents the flattening pressure roller; K represents the finished product of the filter material of the present invention; at the D-D section, the metal wire has not been pre-pressed; at the F-F section, the metal wire is pressed into a small triangular waveform; At the H-H section, the metal wire is pressed into a large triangular waveform; at the J-J section, the filter material is molded), the filter material used for the oil well sand control screen of the present invention can be obtained by the following method:

[0022] 1. Place 400-1200 metal wire rollers (also called windings) neatly on the support, divide the metal wires into four groups on average, and send them to the guide rolle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com