Shaped inlay part and its making method

A technology of insert molding and inserting, which is used in household components, electrical components, instrument parts, etc., can solve the problems of poor mechanical bonding strength, large extrusion deformation, accumulation of residual stress, etc. The effect of high strength and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The insert molding product will be further described in detail below with reference to the accompanying drawings and preferred embodiments.

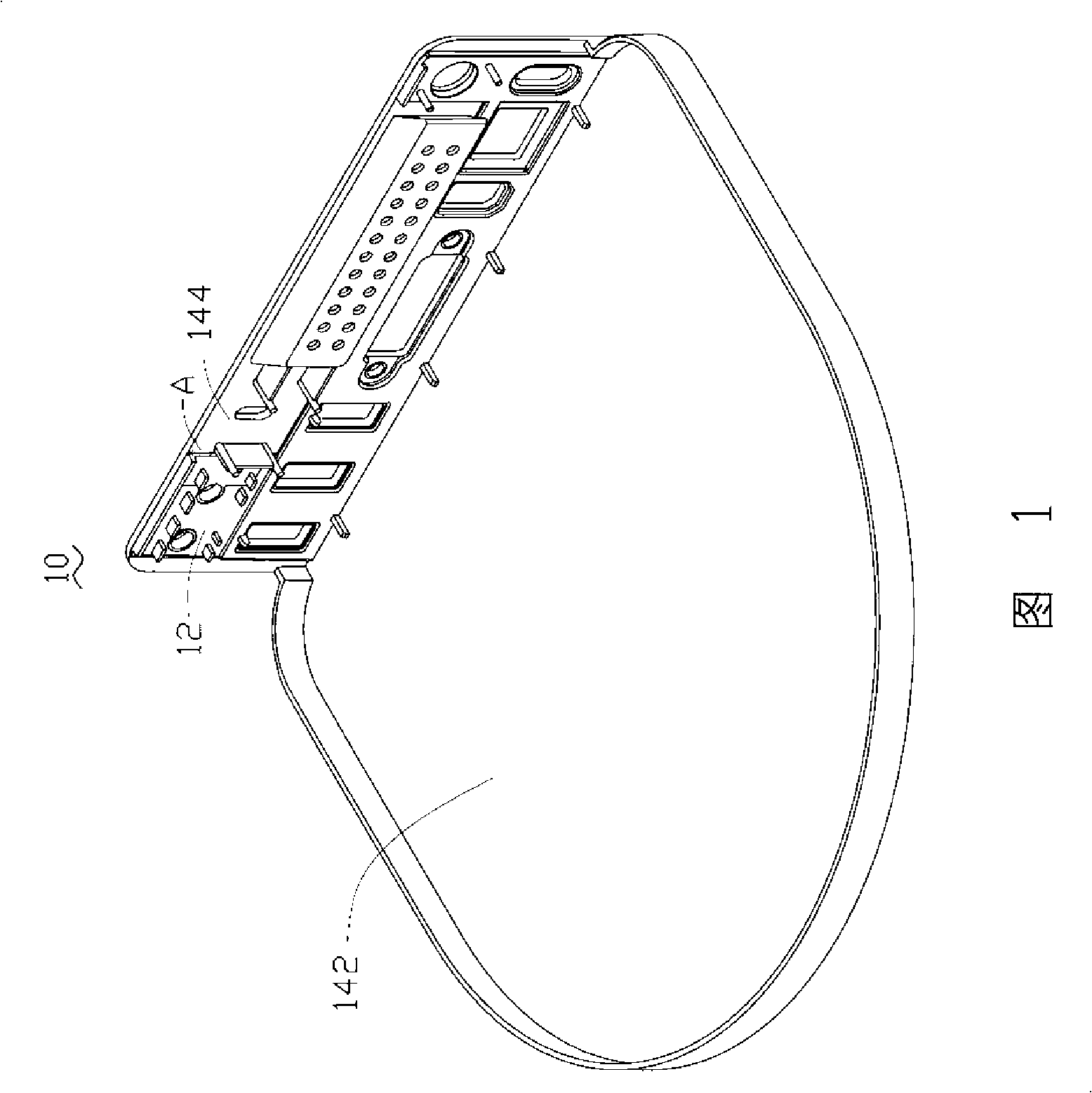

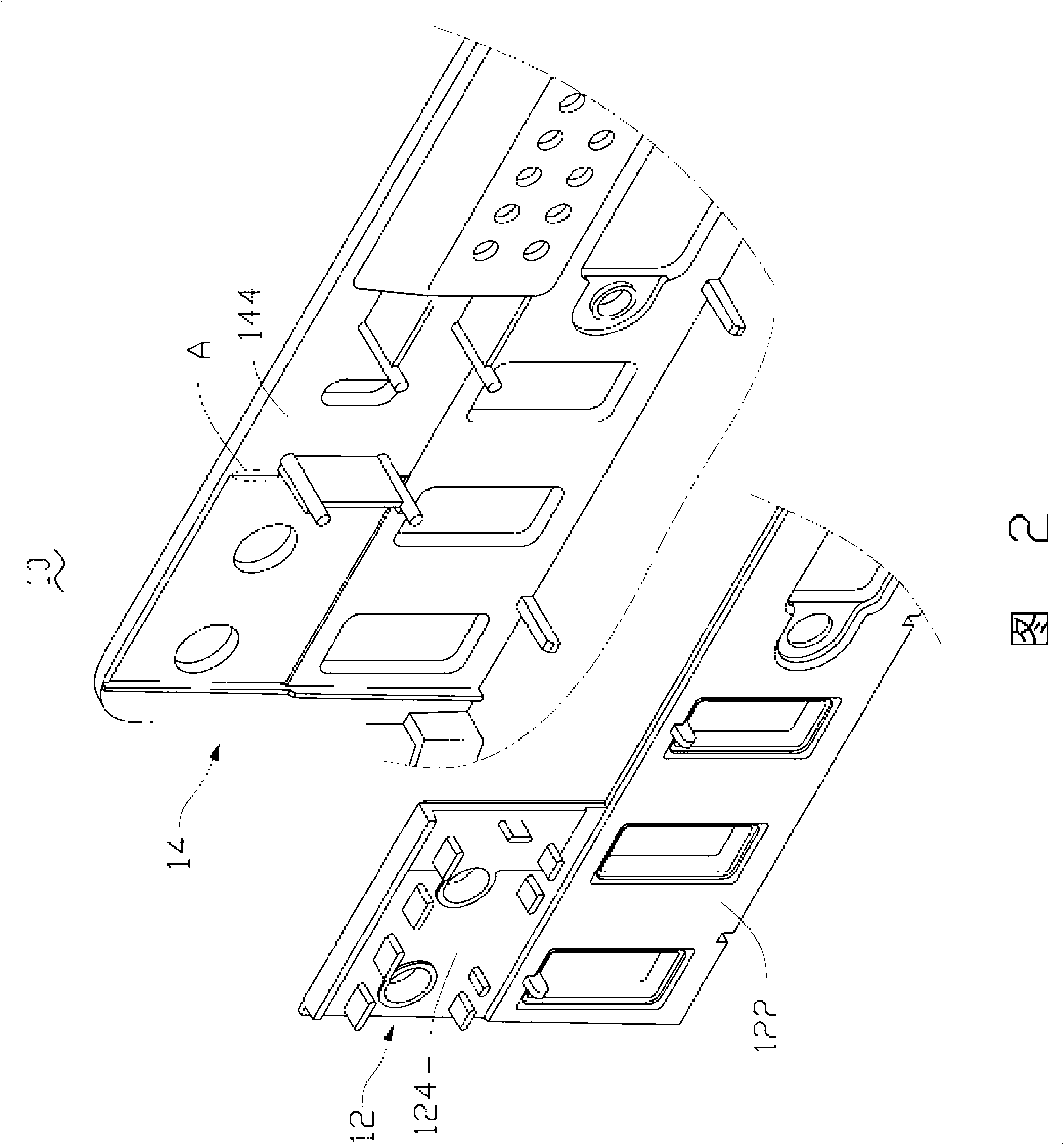

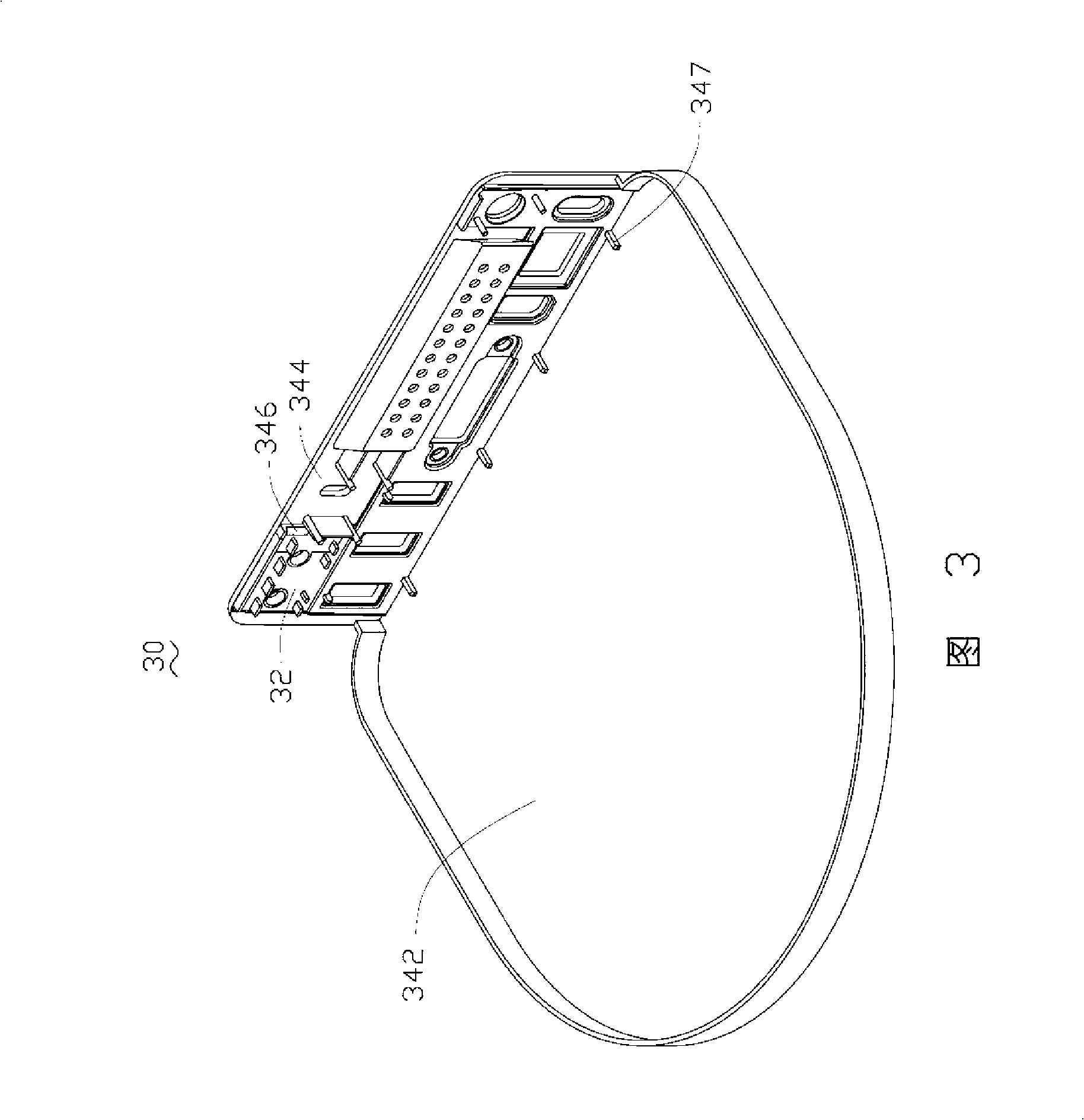

[0014] Please refer to FIG. 3 and FIG. 4 at the same time, which shows an insert molding product 30 according to a preferred embodiment of the present invention. The insert molding product 30 is mainly used in the casing of electronic products, and includes an insert 32 and a plastic part 34 . The insert 32 includes a body portion 322 and an extension portion 324 . The extension portion 324 extends horizontally outward from one end of the side surface of the main body portion 322 . The main body portion 322 and the extension portion 324 form an approximate "L" shape. A protruding portion 326 extending horizontally outward is formed in the middle of the side surface 325 of the extension portion 324 near the center of the main body portion 322 .

[0015] The plastic part 34 includes a receiving portion 342 and a side wall 344, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com