Stereo blowing-ironing machine for shirt

A blower, three-dimensional technology, applied in clothing, applications, hangers, etc., can solve the problems of inability to drive heat energy, influence, convenient operation and unfavorable safety, and achieve the effects of increasing air volume, reducing air blowing noise, and eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

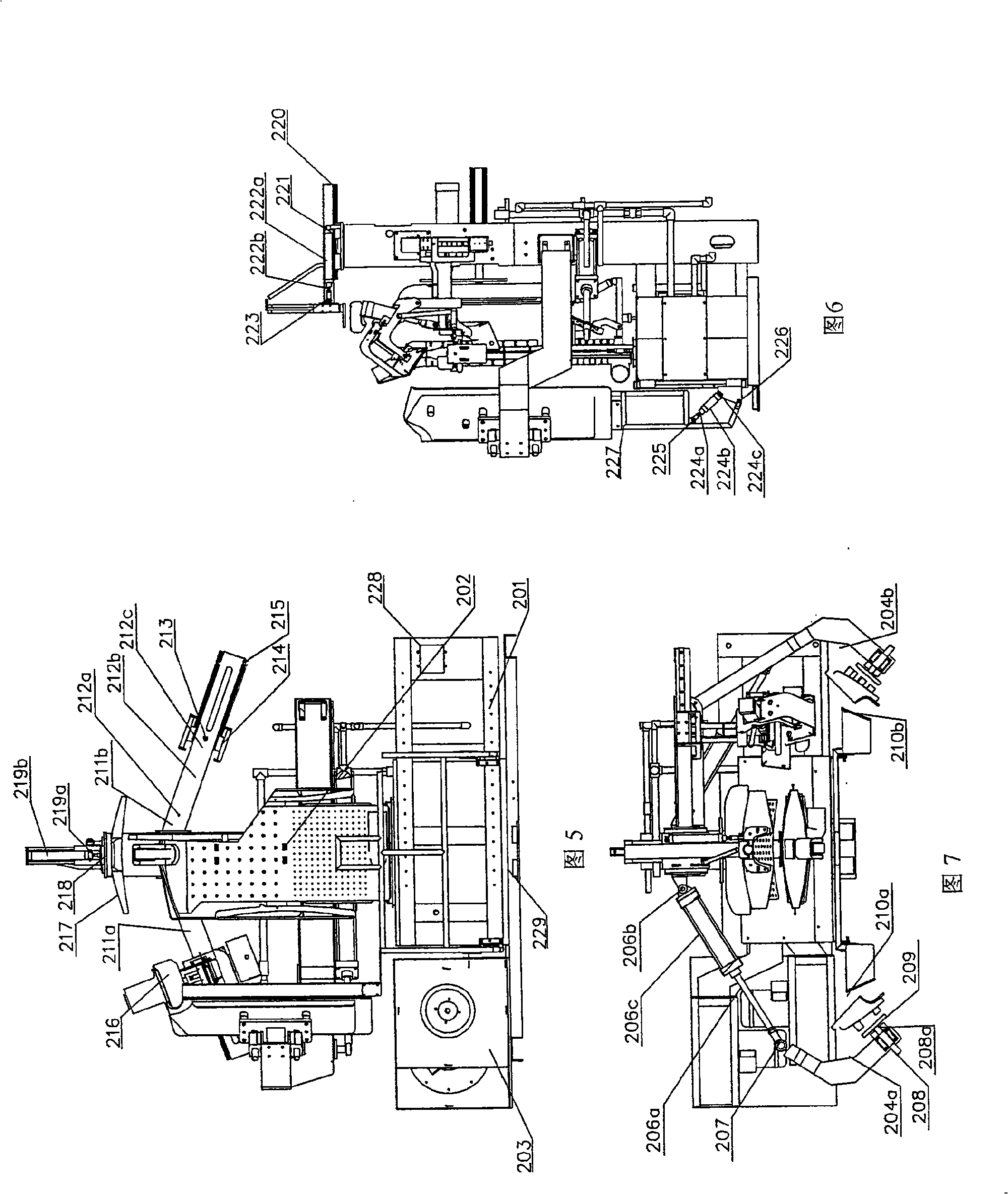

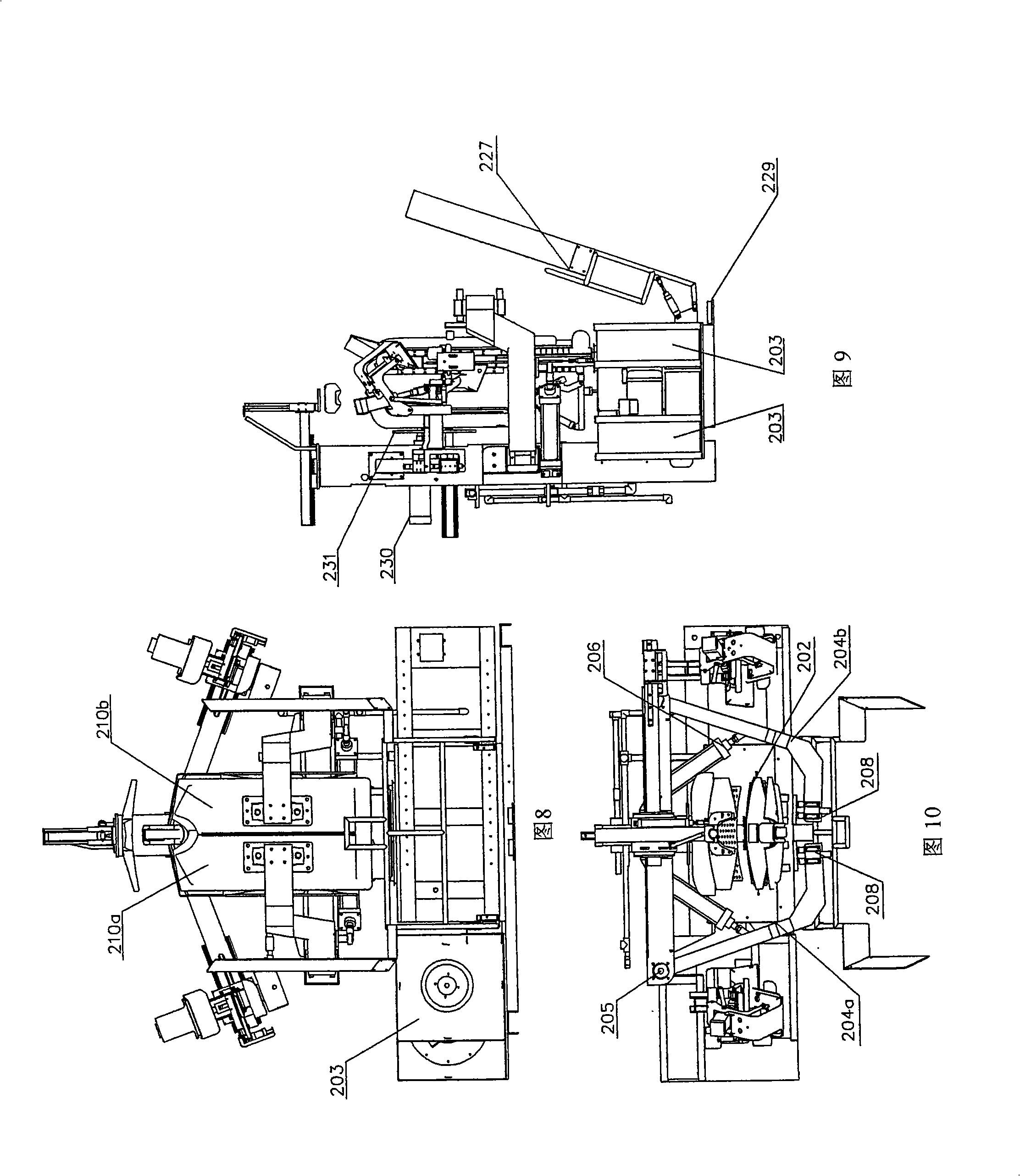

[0022] According to accompanying drawing 5,6,7 and 10, the structural representation of three-dimensional shirt blowing and ironing machine of the present invention, it has a fixing frame 201, and middle mold 202 is fixed on the frame 201 with bolts, and double fan 203 is fixed with bolts On the frame 201, the outlet of the blower fan 203 communicates with the inner cavity of the middle mold 202, and is used to blow air into the shirt enclosed on the middle mold.

[0023] Left and right front mold rocking arms 204 are connected on the frame 201 by main shaft 205; Rocking arm swing cylinder 206 comprises cylinder block 206c, piston rod 206a and tailstock shaft 206b, and its tailstock shaft 206b is hinged with frame 201, and piston rod 206a A joint bearing shaft 207 is hinged with the front mold rocker arm 204a. When working, the left and right front mold rocker arms 204a, 204b are driven by a pair of rocker arm swing cylinders to swing around the respective main shaft 205 to rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com