Electric automobile vector control AC variable-frequency speed regulation system

A vector control, AC frequency conversion technology, applied in electric vehicles, control drives, vehicle components, etc., can solve the problem of not being able to achieve high dynamic performance of DC motors, and achieve the effects of light weight, small size and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

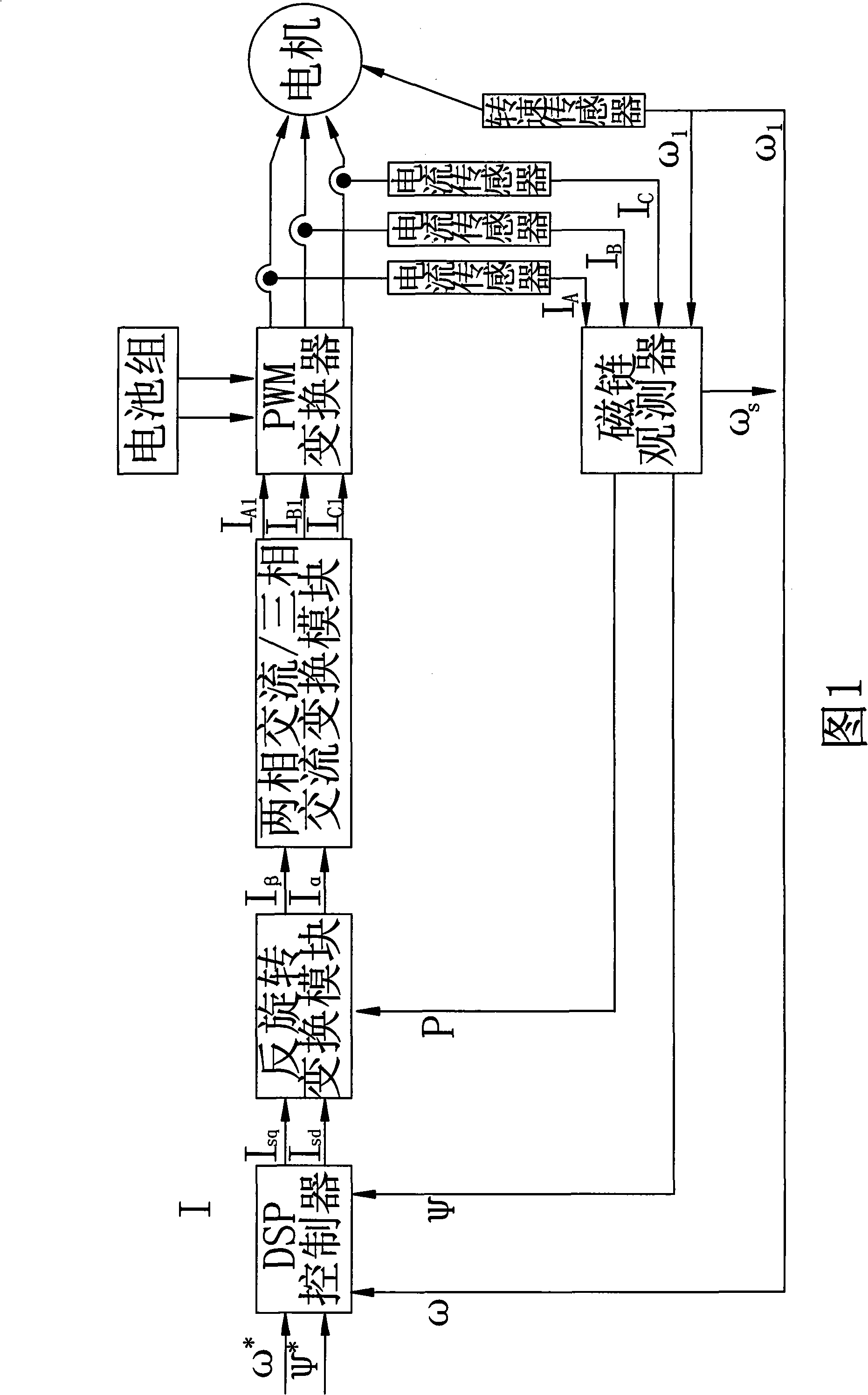

[0024]Fig. 1 is the block diagram of the vector control AC frequency conversion speed regulation system of the specific embodiment of the present invention, as shown in Fig. Conversion module, PWM converter, three-phase AC induction motor, flux linkage observer, battery pack, the battery pack is a 144V or 72V high-energy battery pack, an intelligent power module with high-efficiency three-phase output, 75V (corresponding to a 144V battery pack) or 38V ( Corresponding to 72V battery pack) three-phase AC induction motor, PWM converter adopts IPM intelligent power module or IGBT drive circuit, DSP controller takes TI company TMS320LF2407A as the core, also includes switching power supply, A / D conversion interface circuit, motor speed interface circuit, bus, driving control circuit, etc. (not shown in the figure).

[0025] The driver's stepping on the accelerator signal is processed by the interface circuit and sent to the DSP controller. After calculation, the signal speed ω* and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com