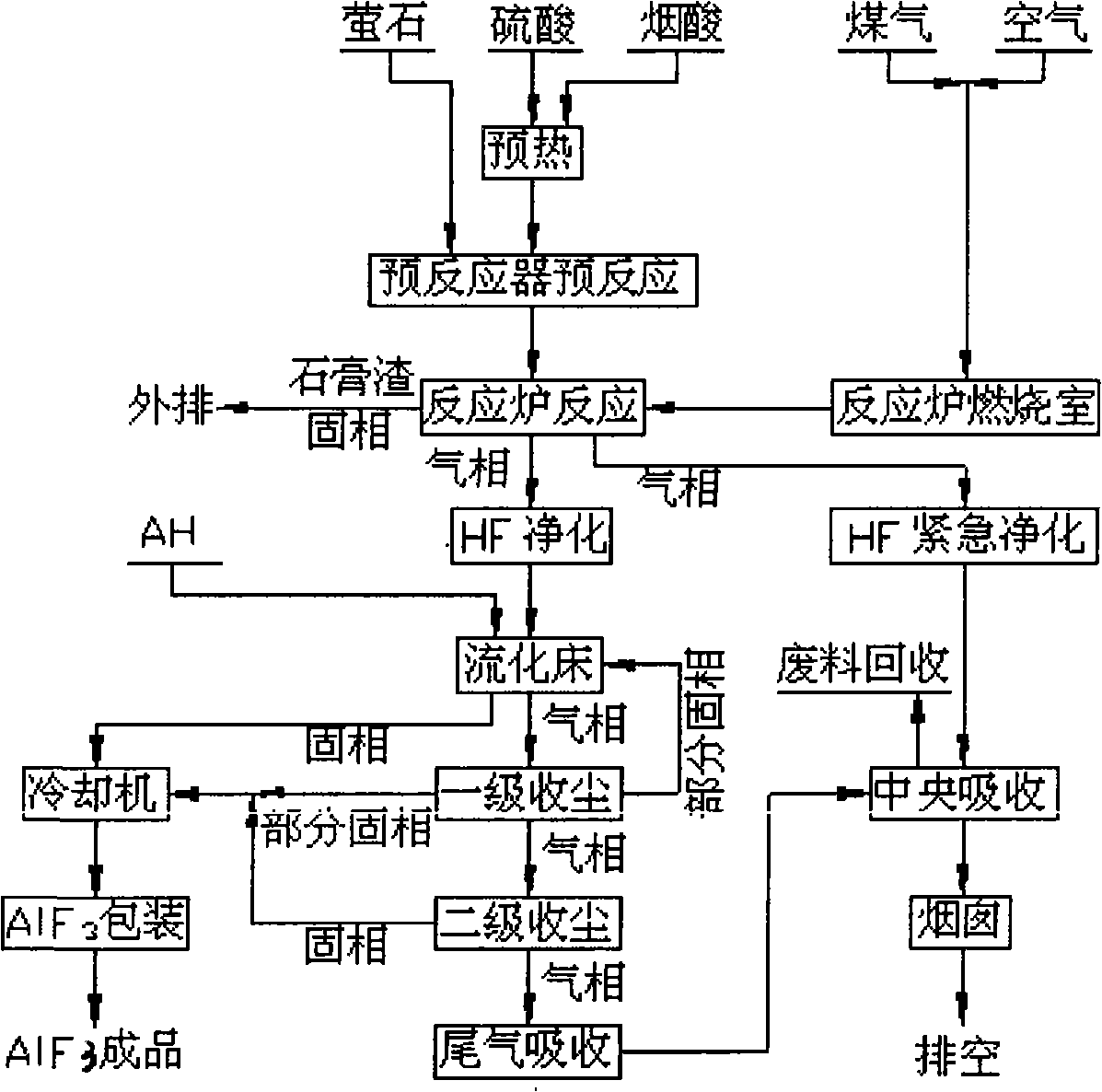

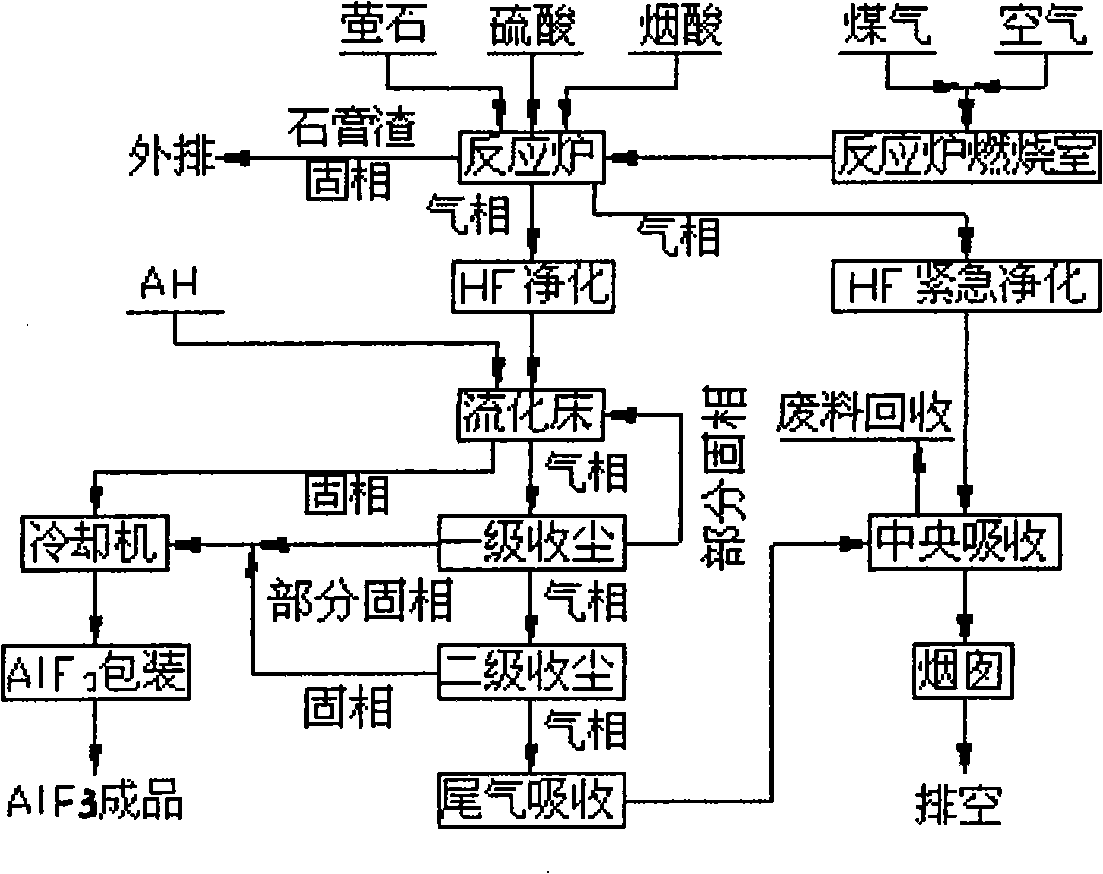

Technique for producing aluminum fluoride by dry method

A production process, aluminum fluoride technology, applied in the field of dry aluminum fluoride production process, can solve the problems of pre-reactor production impact, improper control of reaction parameters, etc., to expand production capacity, improve equipment operation rate, and save equipment Maintenance cost and effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Dry aluminum fluoride production process, adding concentrated sulfuric acid with a mass concentration of 98% and 105% nicotinic acid to the fuming acid reactor at room temperature, and the mixed acid obtained after mixing is fully reacted with fluorite in the reactor to obtain HF gas. After the HF gas is purified, it enters the fluidized bed from the bottom of the fluidized bed; the solid residue CaSO 4 One part returns to the kiln head from the kiln tail, and the other part is discharged through the slag discharge screw. Aluminum hydroxide enters the fluidized bed from the upper part of the fluidized bed, and reacts with HF gas entering the fluidized bed from the bottom to form AlF 3 and water. Coarse AlF 3 The material enters the cooler through the discharge screw, fine AlF 3 Materials and tail gas enter the first-stage cyclone for dust collection, and part of the fine material obtained by the first-stage dust collection enters the bottom of the fluidized bed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com