Technique for producing heat-resistance ceramic non-sticking container

A production process and heat-resistant technology, applied to clay products, other household utensils, household utensils, etc., can solve the problem of not being able to produce qualified heat-resistant ceramic non-stick containers, non-stick coatings are treated differently in cold treatment, and non-stick coatings are easy to fall off and other issues, to achieve the effect of increasing hardness, improving durability, improving smoothness and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

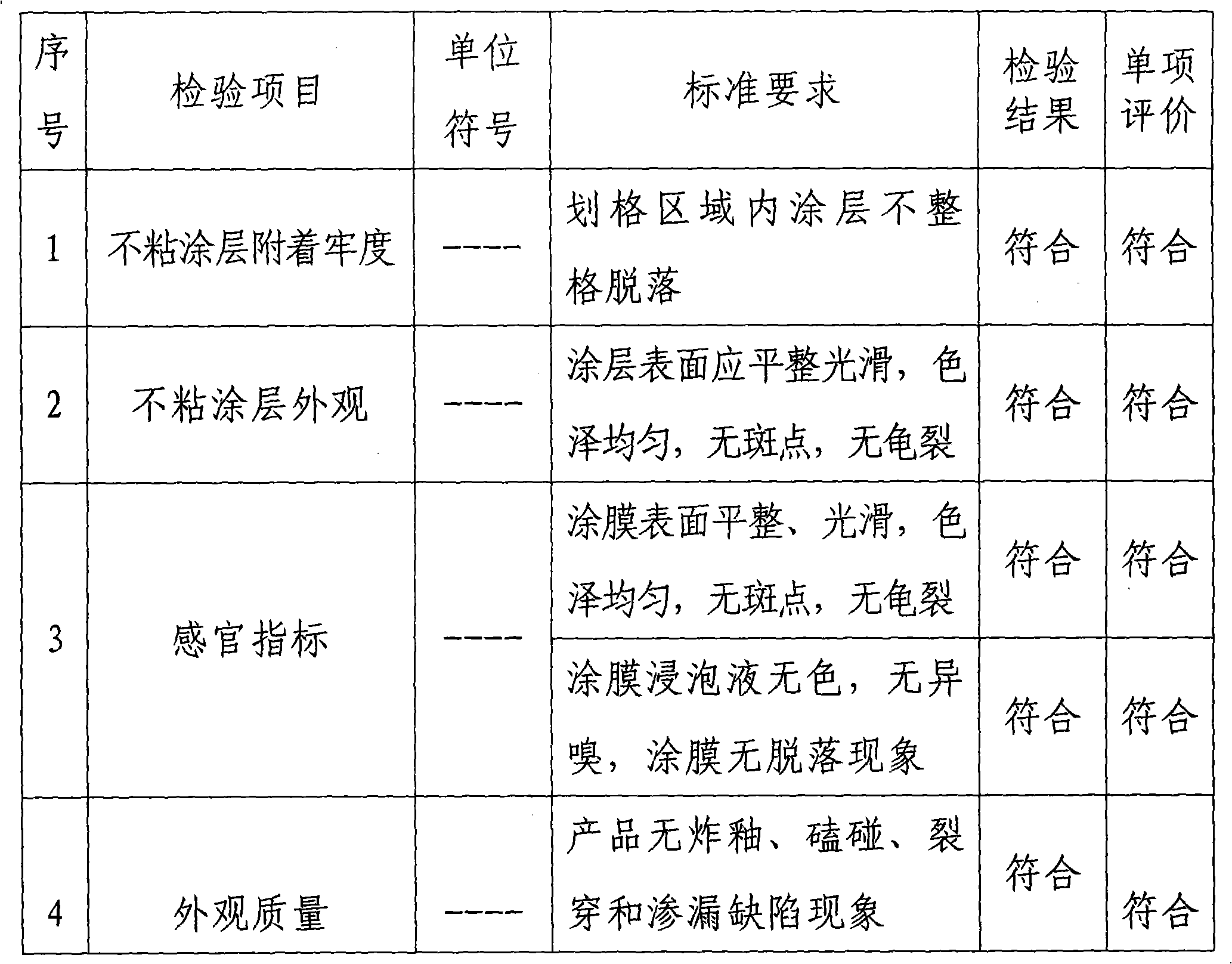

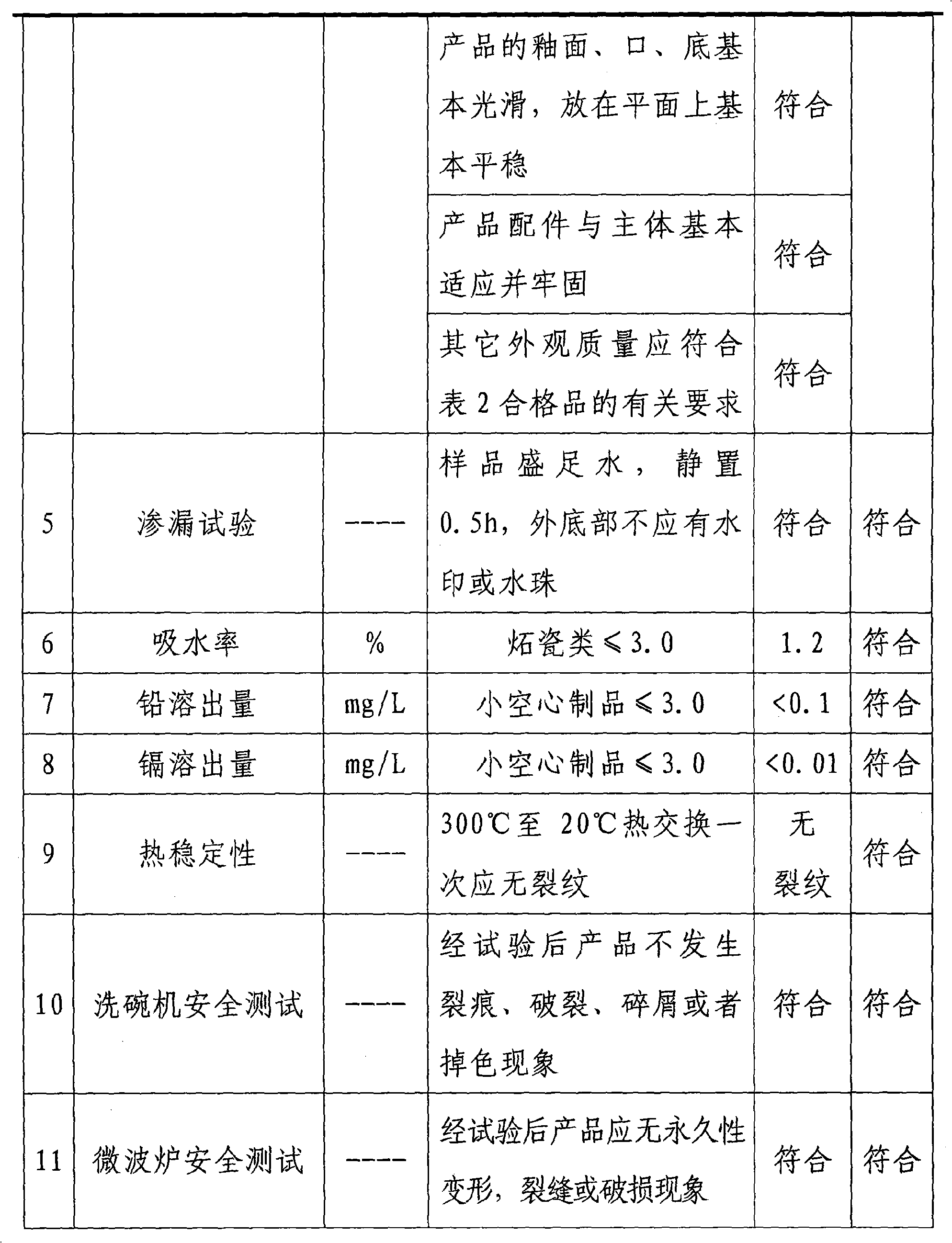

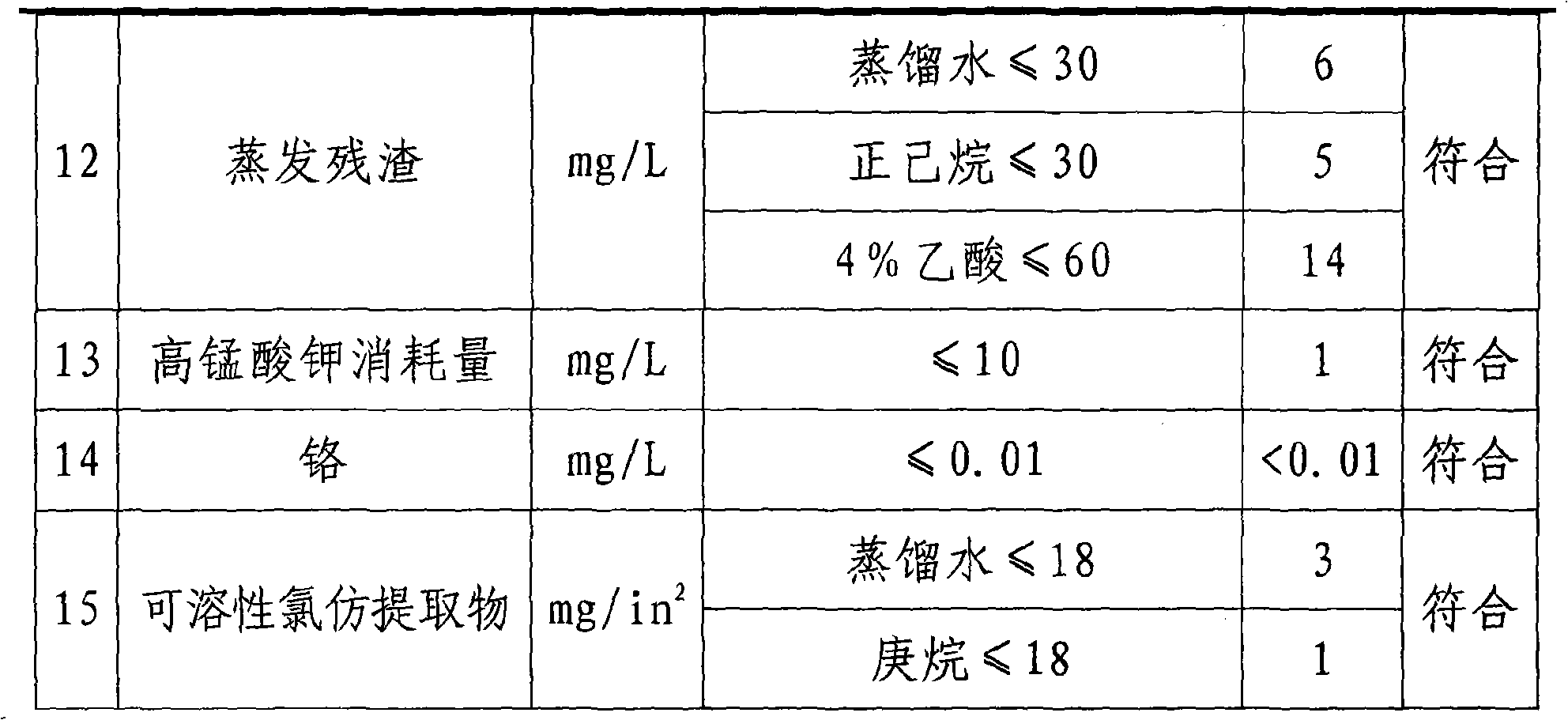

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below through examples.

[0029] Add cordierite to ordinary ceramic mud and mix evenly, the addition amount is 30% of the total weight of the mud, and heat-resistant ceramic mud is obtained; the earthy pot-shaped green body is made by rolling forming method; the earthy pot-shaped green body is made The body is repaired through a combination of mechanical trimming, manual trimming, and water washing; and partial glazing is performed on the outer surface of the earthy pot-shaped body; the body after partial glazing is placed in a gas tunnel kiln for firing. The temperature is 1250°C, the firing time is 9 hours, and the atmosphere is first oxidized and then reduced during firing; the inner cavity of the product is sandblasted and roughened with a mechanical sandblasting machine, and the surface of the product is dedusted with an air gun, and then the product is put into Dehumidification in the drying furnace, the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com