Hollow tube for filling concrete

A technology of hollow tubes and hollow components, applied in building components, floors, buildings, etc., can solve the problems of small deformation resistance, separation, and large difference in vertical and horizontal stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

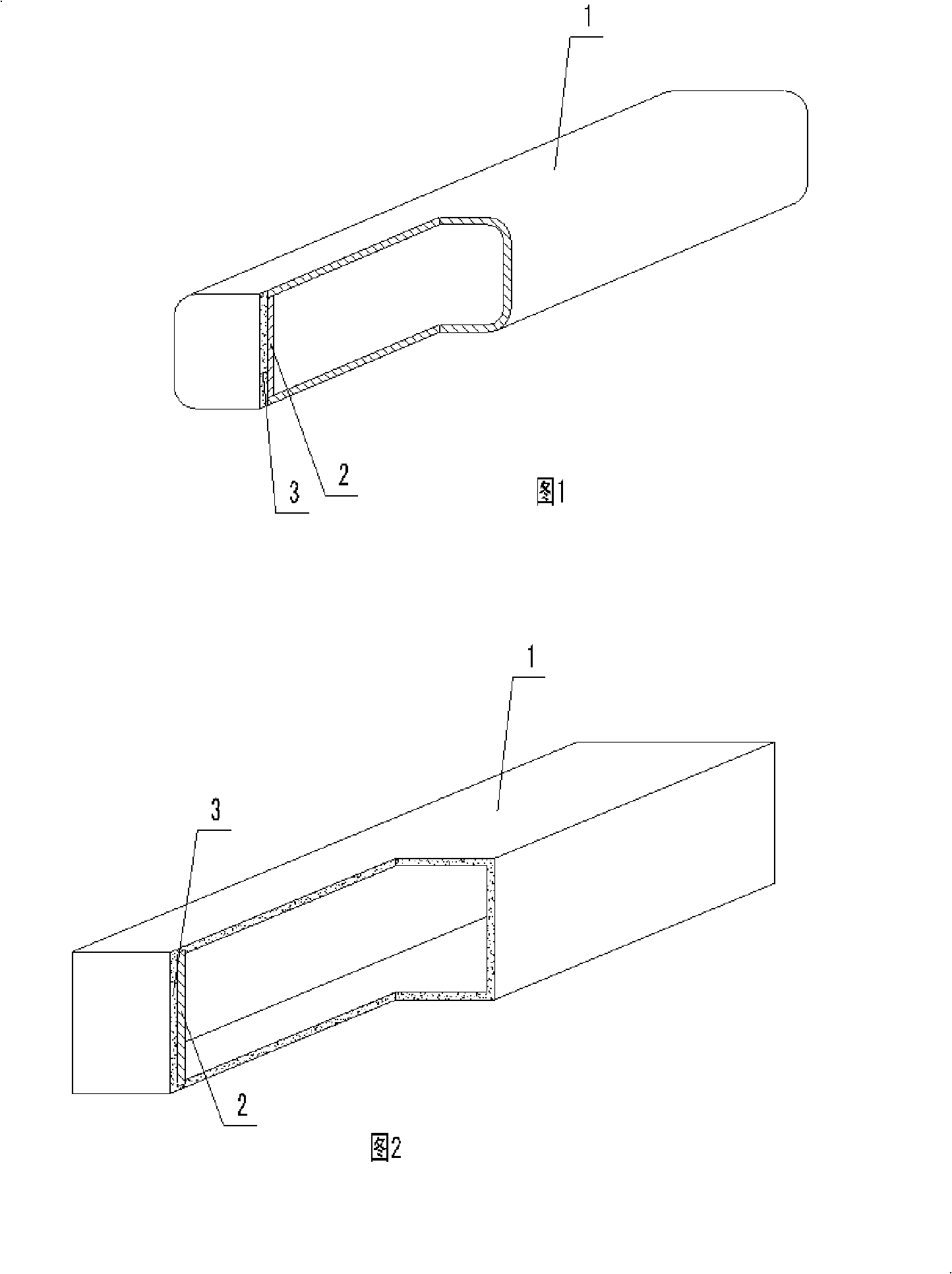

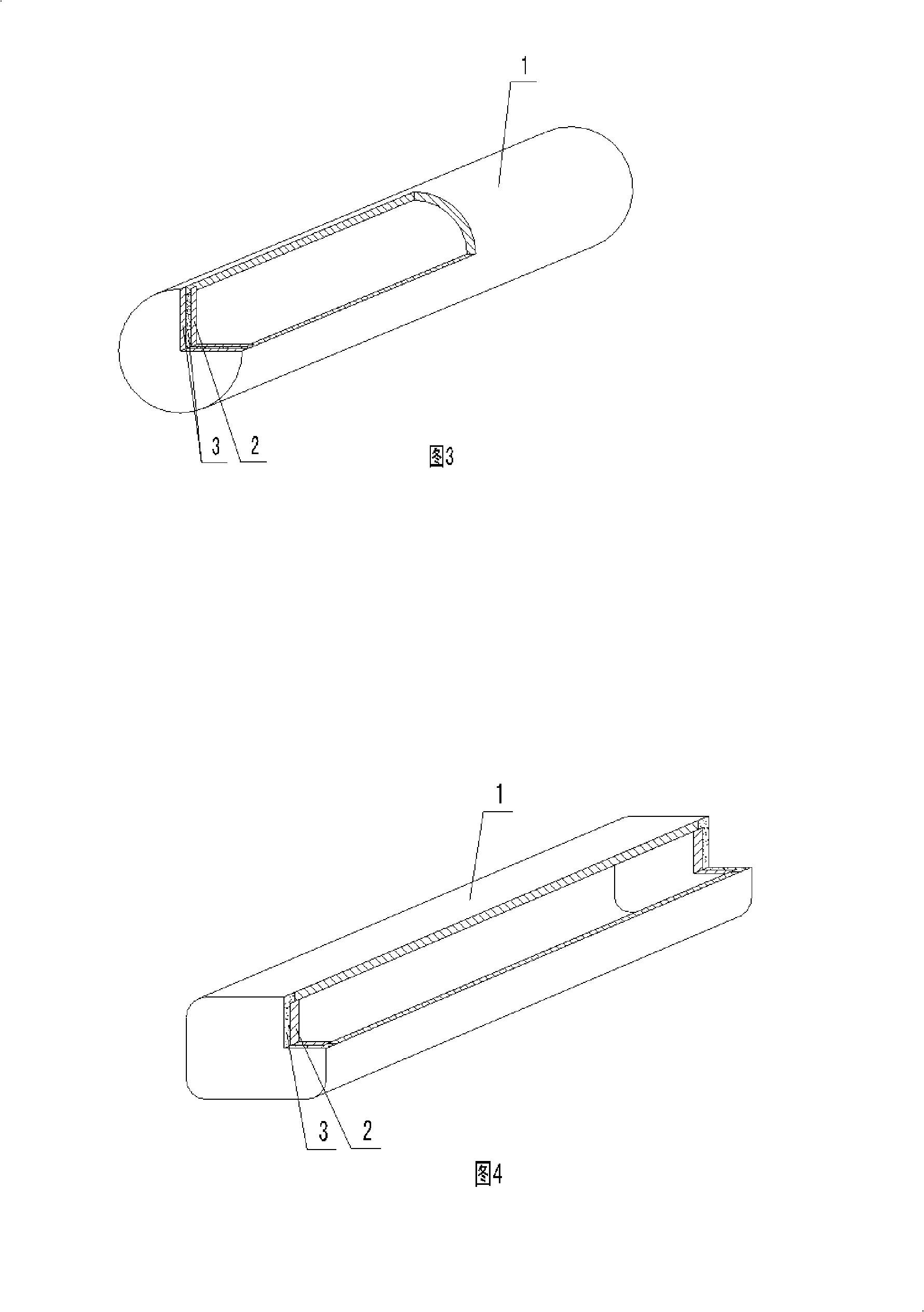

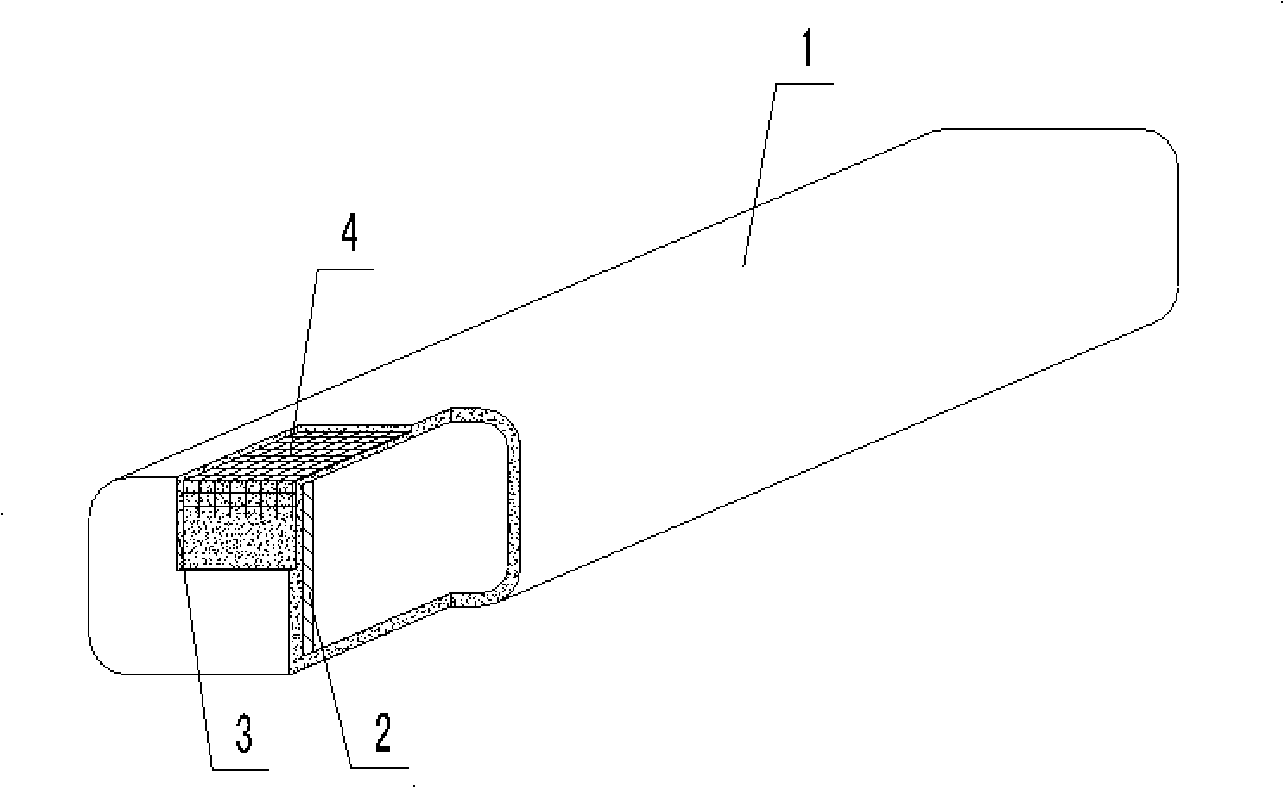

[0061] As shown in the accompanying drawings, the present invention includes a pipe body 1 and a prefabricated plug 2. Two prefabricated plugs 2 seal off both ends of the pipe body 1 to form a closed hollow pipe. It is characterized in that at least one end of the hollow pipe is prefabricated. The head 2 is provided with a post-adhesive lamination layer 3, and the post-adhesion lamination layer 3 bonds the prefabricated plug 2 and the pipe body 1 into an integral hollow member, and the pipe body 1 is provided with a reinforcing member 5, which is Stiffeners or / and stiffeners or / and ribs or / and cables. In each drawing, 1 is a pipe body, 2 is a prefabricated plug, and 3 is a laminated layer. In the following drawings, those with the same number have the same description. As shown in Figure 1, two plugs 2 close the two ends of the pipe body 1 to form a cl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap