Engine wind-guiding cover structure

A wind deflector and engine technology, applied in air cooling, engine components, machines/engines, etc., can solve problems such as shortened service life of the engine 1, reduced cooling efficiency of the engine 1, deformation of the engine 1 parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to understand the structure of the present invention and the effect that can be achieved more easily, it is described as follows in conjunction with the drawings:

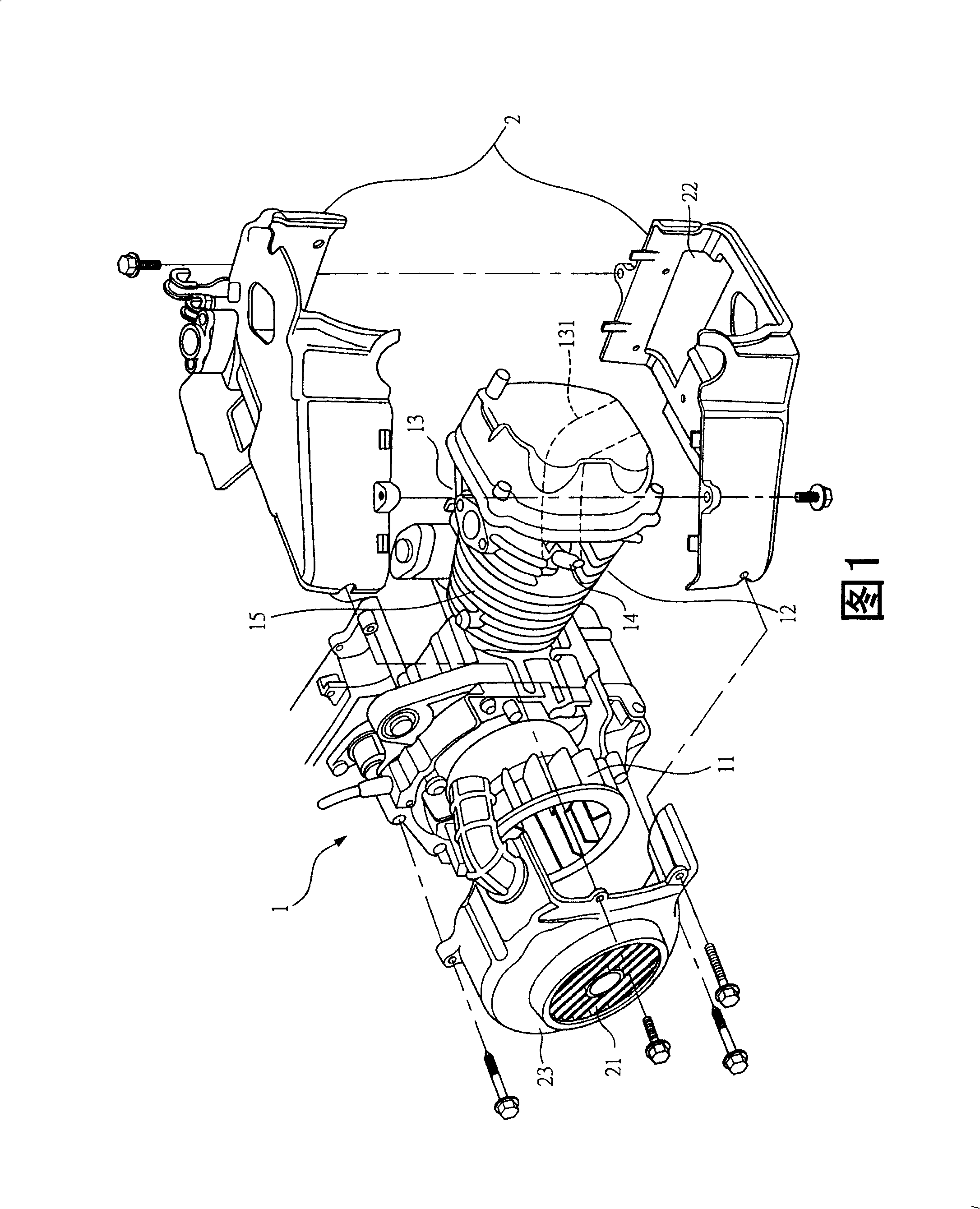

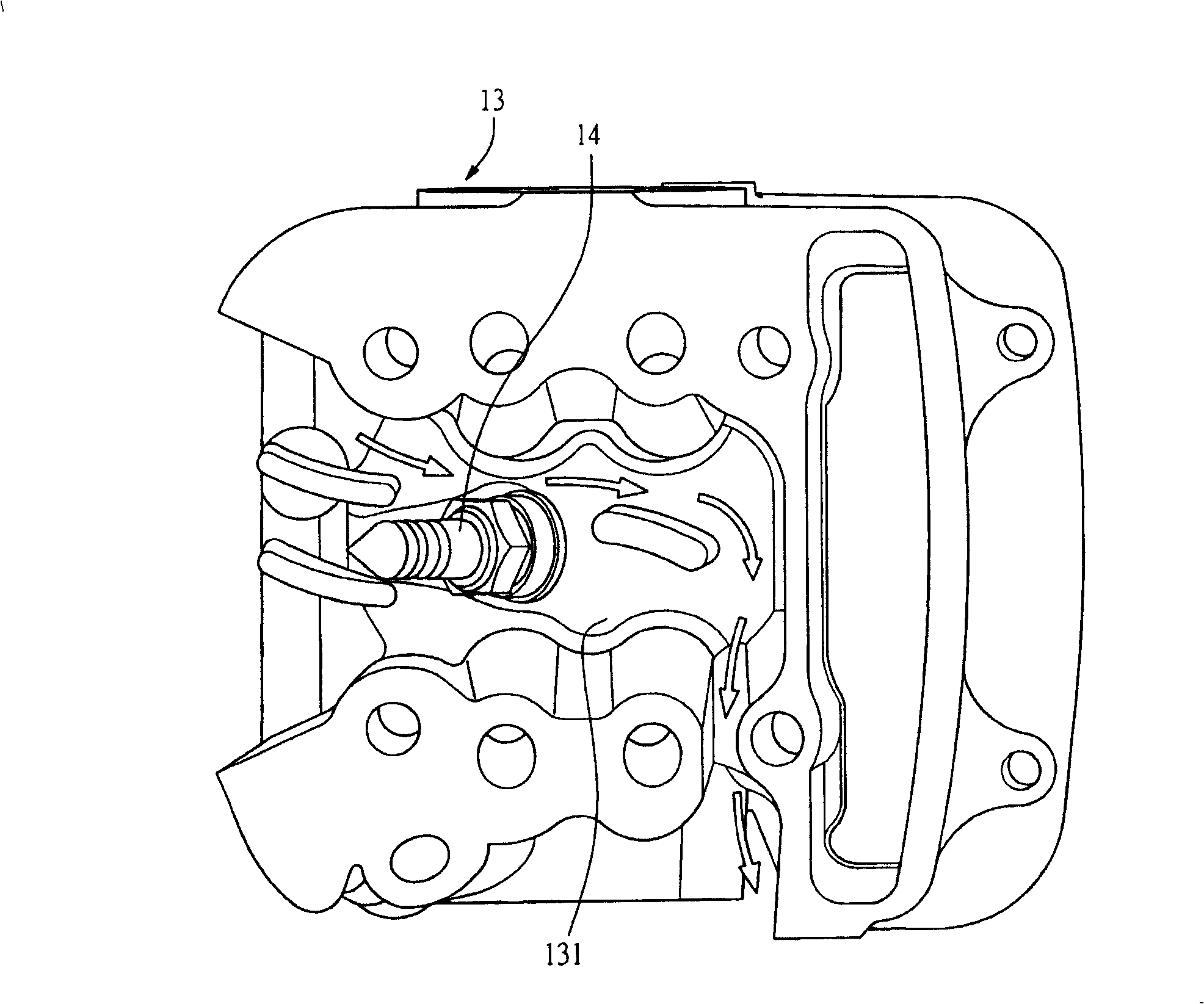

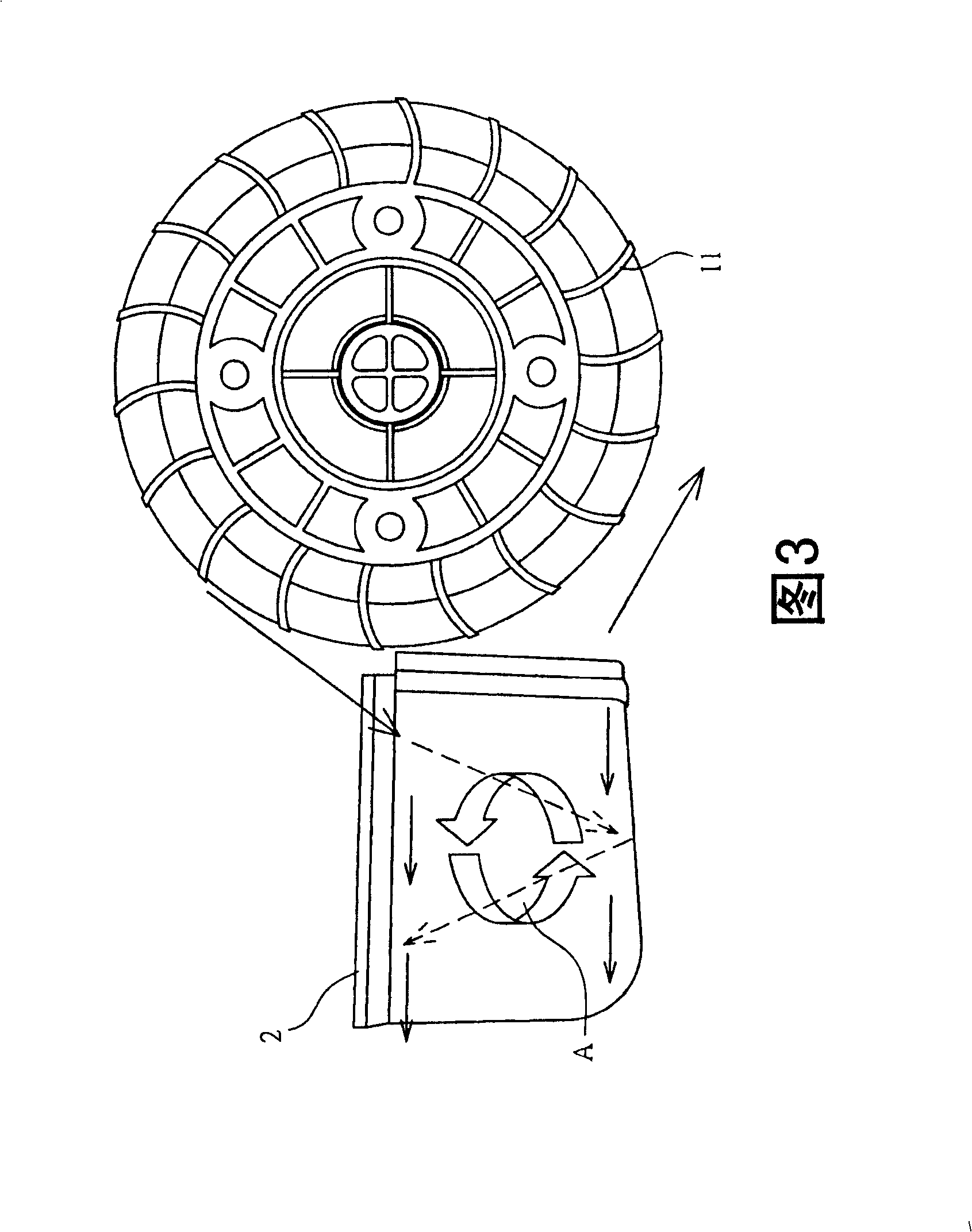

[0015] First, see Figure 4 As shown, the engine 3 of the engine air guide cover structure of the present invention includes a crankcase 31, a crankshaft 32 connected with the crankcase 31, a cylinder body 33 mounted on the crankcase 31, and a cylinder body 33 stretched in the cylinder body 33. The piston 34 , the cylinder head 35 arranged on the cylinder body 33 , and the cooling fan 36 driven by the crankshaft 32 . In addition, in order to increase the heat dissipation area of the cylinder body 33 and the cylinder head 35, a plurality of cooling fins 331 and 351 arranged at intervals will be arranged on the cylinder body 33 and the cylinder head 35; Explosion, the gas pressure of its expansion will produce a thrust to push the piston 34 to reciprocate up and down. When the piston 34 descends, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com