Floating shaft cog-wheel coupling correcting device

A technology of calibrating device and coupling, applied in the direction of angle/taper measurement, etc., can solve the problems of not very strict installation accuracy requirements, unusable couplings, increase the number of calibrations, etc., so as to shorten the maintenance time, reduce the maintenance cost, The effect of prolonging the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the calibration reference plane in this embodiment is the outer circular surface of the floating shaft 5 .

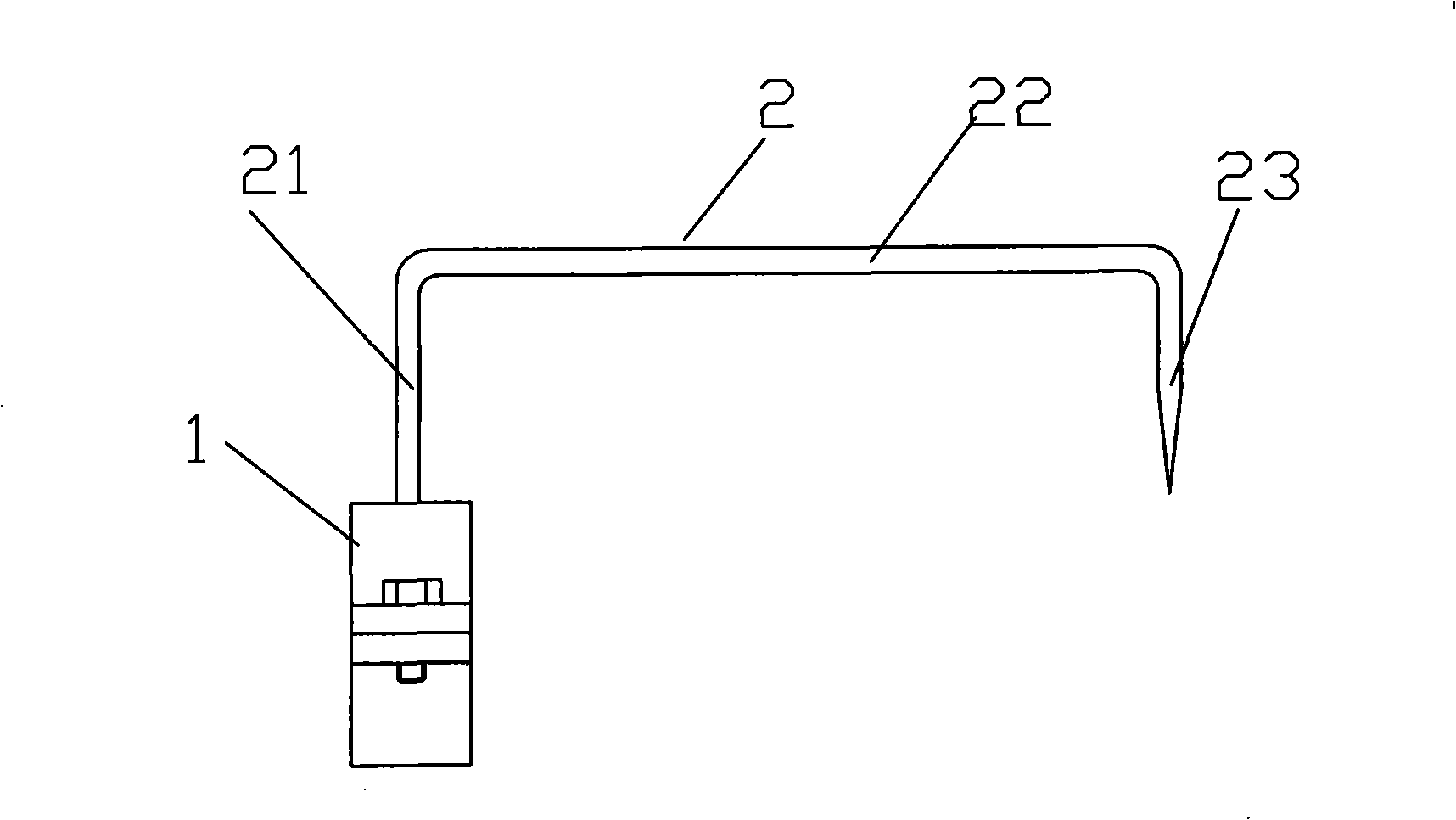

[0021] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention, figure 2 for figure 1 side view, Figure 5 It is a schematic diagram of the use state of the present invention, as shown in the figure: the floating shaft gear coupling correction device of this embodiment includes a ring body snap ring 1 and a correction rod 2 composed of two half rings, and the ring body snap ring 1. When in use, the gap fit is sleeved on the outer circle of the coupling 4 connected to the floating shaft 5. In this embodiment, the inner diameter of the ring snap ring 1 is equal to the outer diameter of the coupling 4 connected to the floating shaft 5, forming a ring One side of the two halves of the body snap ring 1 is connected by a hinge, and the other side is connected by bolts. During installation, the connecting bolts are adjust...

Embodiment 2

[0023] Embodiment 2, the calibration reference plane in this embodiment is the end face of the motor brake connected to the floating shaft.

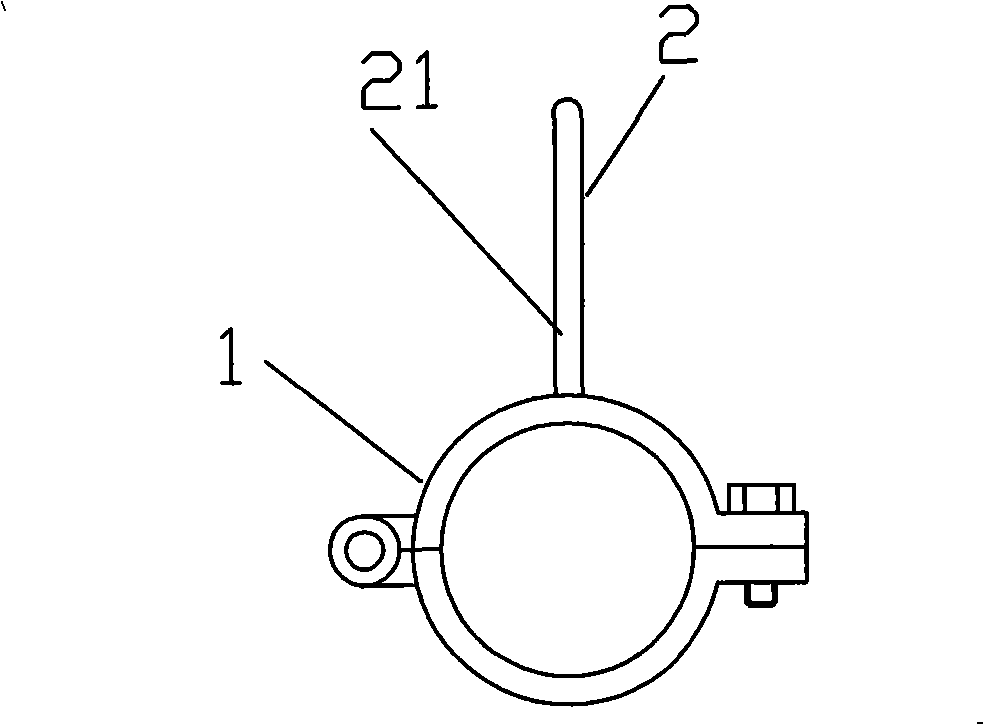

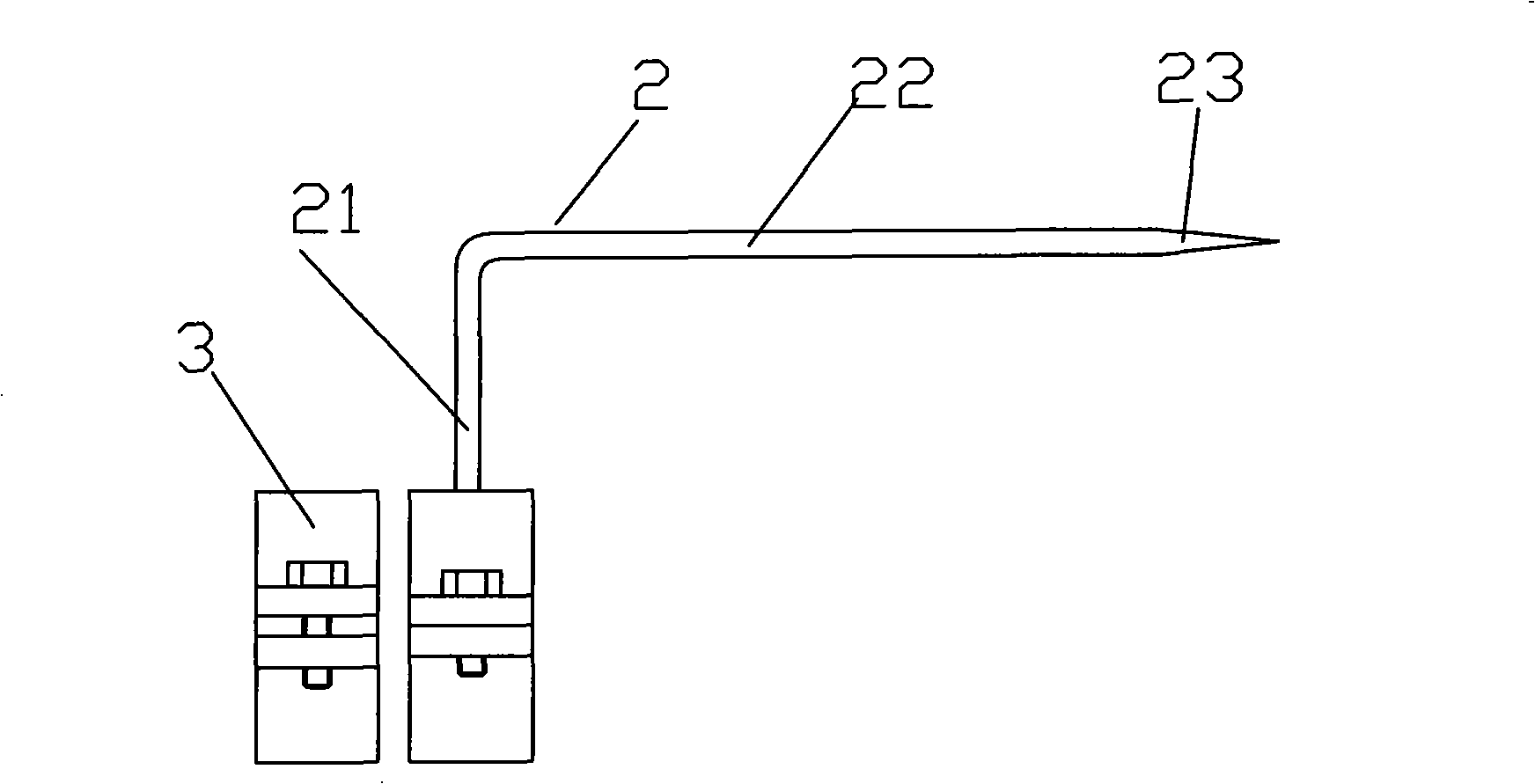

[0024] image 3 It is a schematic structural diagram of Embodiment 2 of the present invention, Figure 4 It is a schematic diagram of the structure of the fixed ring of the torus, Figure 5 It is a schematic diagram of the use state of the present invention, as shown in the figure: the floating shaft gear coupling correction device of this embodiment includes a ring body snap ring 1 and a correction rod 2 composed of two half rings, and the ring body snap ring 1. When in use, it fits loosely on the outer circle of the floating shaft 5. In this embodiment, the inner diameter of the torus clasp 1 is equal to the diameter of the outer circle of the floating shaft 5, and one side of the two halves of the torus clasp 1 is connected by a hinge. , the other side is connected by bolts. During installation, ensure that the ring body snap ring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com