Blast furnace hearth water temperature difference alarming control method

A control method and technology of water temperature difference, applied to blast furnaces, blast furnace details, blast furnace components, etc., can solve problems such as lagging of measures, achieve the effects of reducing impact, prolonging the life of one generation, and modifying the area and length of air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

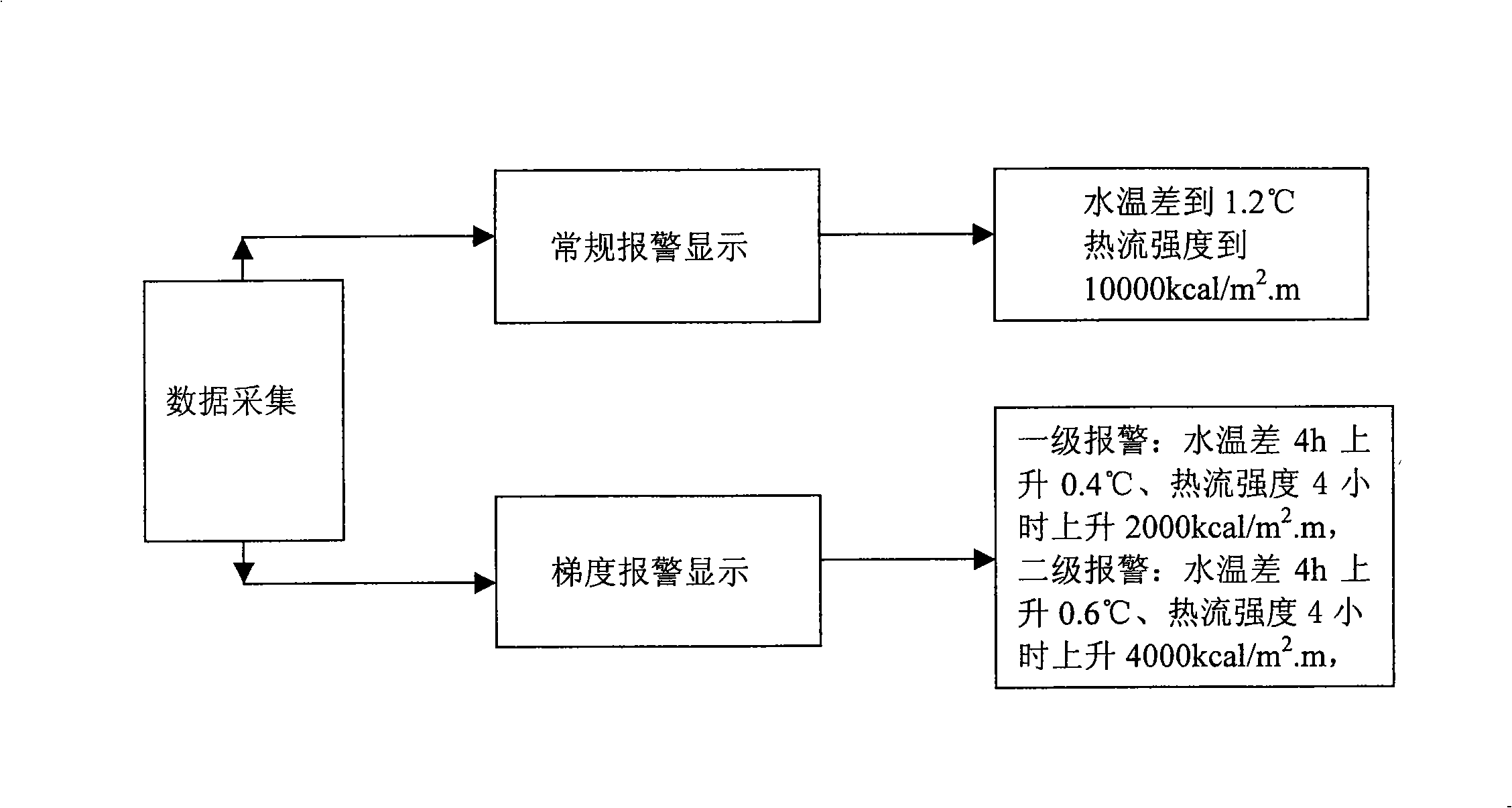

[0007] Referring to the accompanying drawings, a gradient alarm program is added to the operation software of the blast furnace hearth automatic monitoring system, so that the system can reach the set water temperature difference and heat flow intensity value of the hearth stave within the set time range, divided into Two-level alarm, the first level is a yellow alarm, that is, the water temperature difference rises by 0.4°C within 4 hours, and the heat flow intensity rises by 2000kcal / m (normally below 1.0°C) 2 .h, (normally at 8000kcal / m 2 .h or less) the second level is a red alarm, that is, the water temperature difference rises by 0.6°C and the heat flow intensity rises by 4000kcal / m within 4 hours 2 .h, in actual application, through the two-level gradient alarm, effective measures such as shutting off the wind and cooling the furnace, lengthening the tuyere and blocking the tuyere were adopted to avoid greater losses. Practice has proved that the gradient alarm system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com