Electrolyte for lithium ion rechargeable battery and lithium ion rechargeable battery including the same

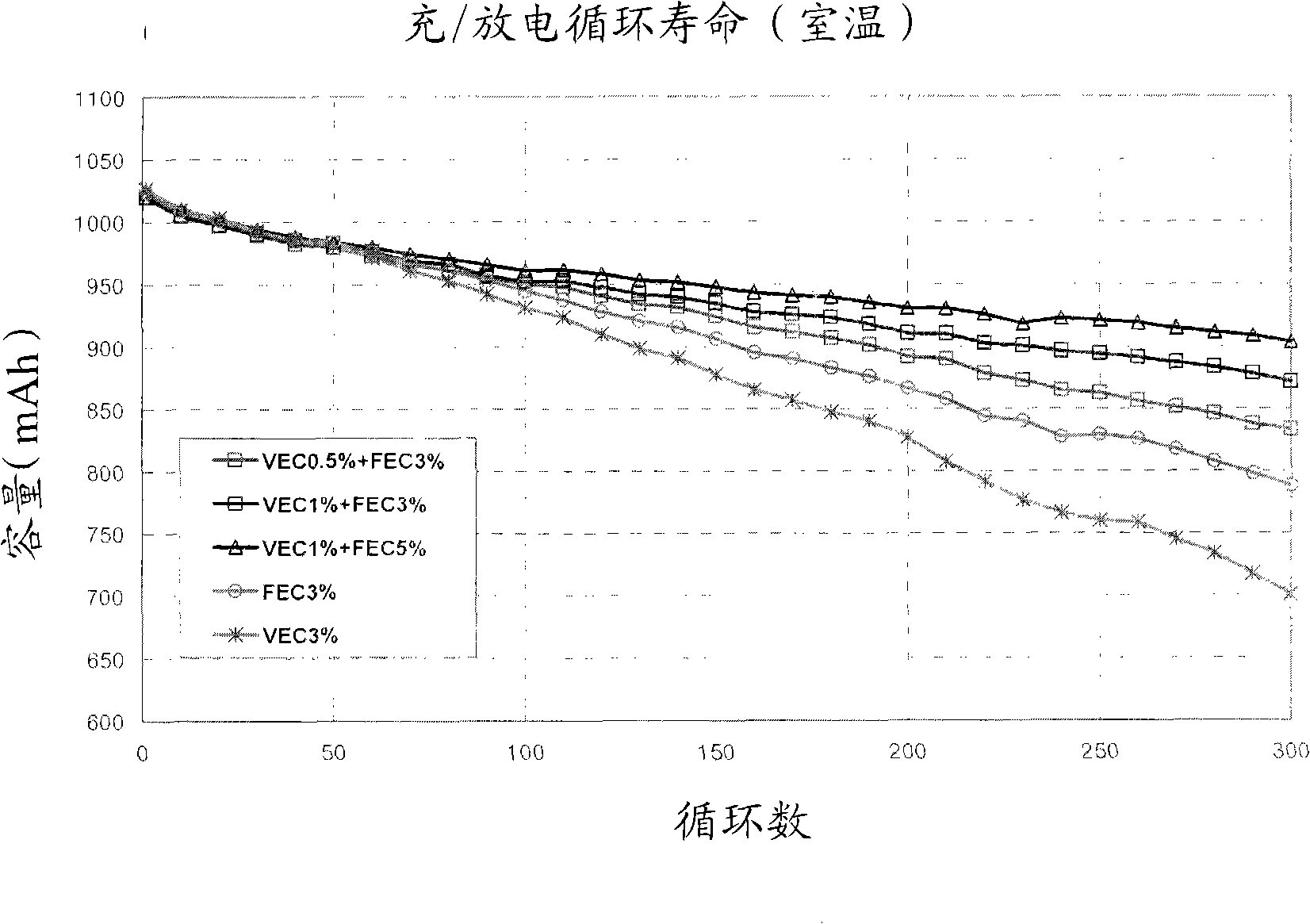

A recharging and electrolyte technology, applied in the field of electrolyte, can solve the problems of other battery performance deterioration, charge/discharge cycle performance reduction, etc., and achieve the effect of maintaining cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

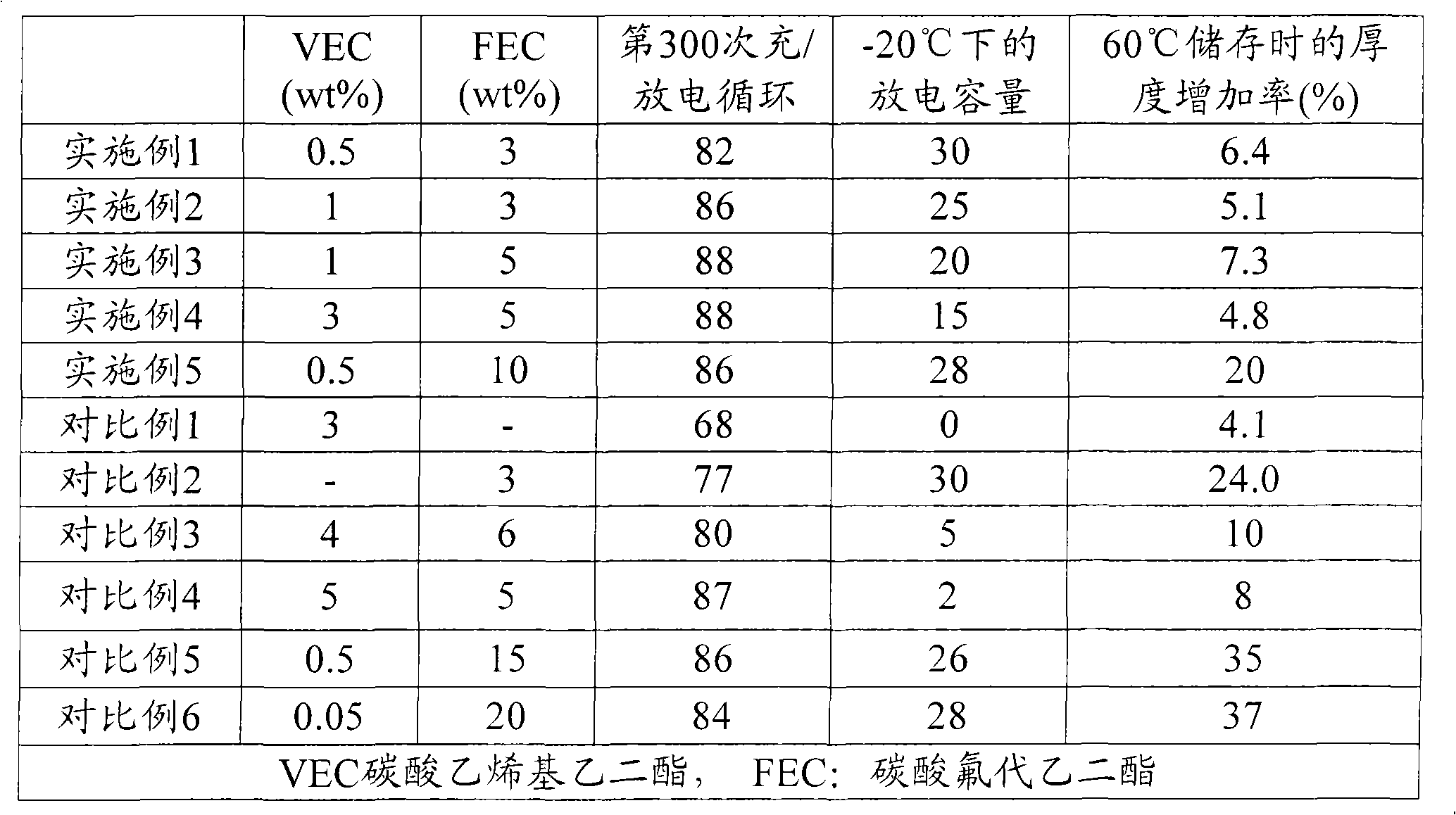

Embodiment 1

[0044] LiCoO as the cathode active material 2 , polyvinylidene fluoride (PVDF) as a binder and carbon as a conductive material are mixed in a weight percentage of 92:4:4, and then dispersed in N-methyl-2-pyrrolidone (NMP) to prepare a cathode slurry. The slurry was coated on a 20 micron thick aluminum foil, dried and rolled to obtain a cathode. Artificial graphite as an anode active material, styrene-butadiene rubber as a binder, and carboxymethyl cellulose as a thickener were mixed in a weight percentage of 96:2:2, and then dispersed in water to prepare an anode slurry. The slurry was coated on a 15 micron thick copper foil, dried and rolled to obtain an anode. After a 20 μm-thick film separator made of polyethylene was inserted between the above-mentioned electrodes, it was rolled up, compressed and inserted into an angular tank measuring 55×34×50 mm. An electrolytic solution was injected into the angular tank to prepare a lithium rechargeable battery. Described electrol...

Embodiment 2

[0046] This example was carried out in the same manner as Example 1, except that 1 wt% of vinyl ethylene carbonate and 3 wt% of fluoroethylene carbonate were added.

Embodiment 3

[0048] This example was carried out in the same manner as Example 1, except that 1 wt% of vinyl ethylene carbonate and 5 wt% of fluoroethylene carbonate were added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| face spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com