Method for improving the texture of fermented milk

A technology for fermented milk and lactalbumin, which is applied in the field of fermented milk, can solve the problems of quality decline, taste deterioration of fermented milk, and unsuitable for long-term fermentation to produce fermented milk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

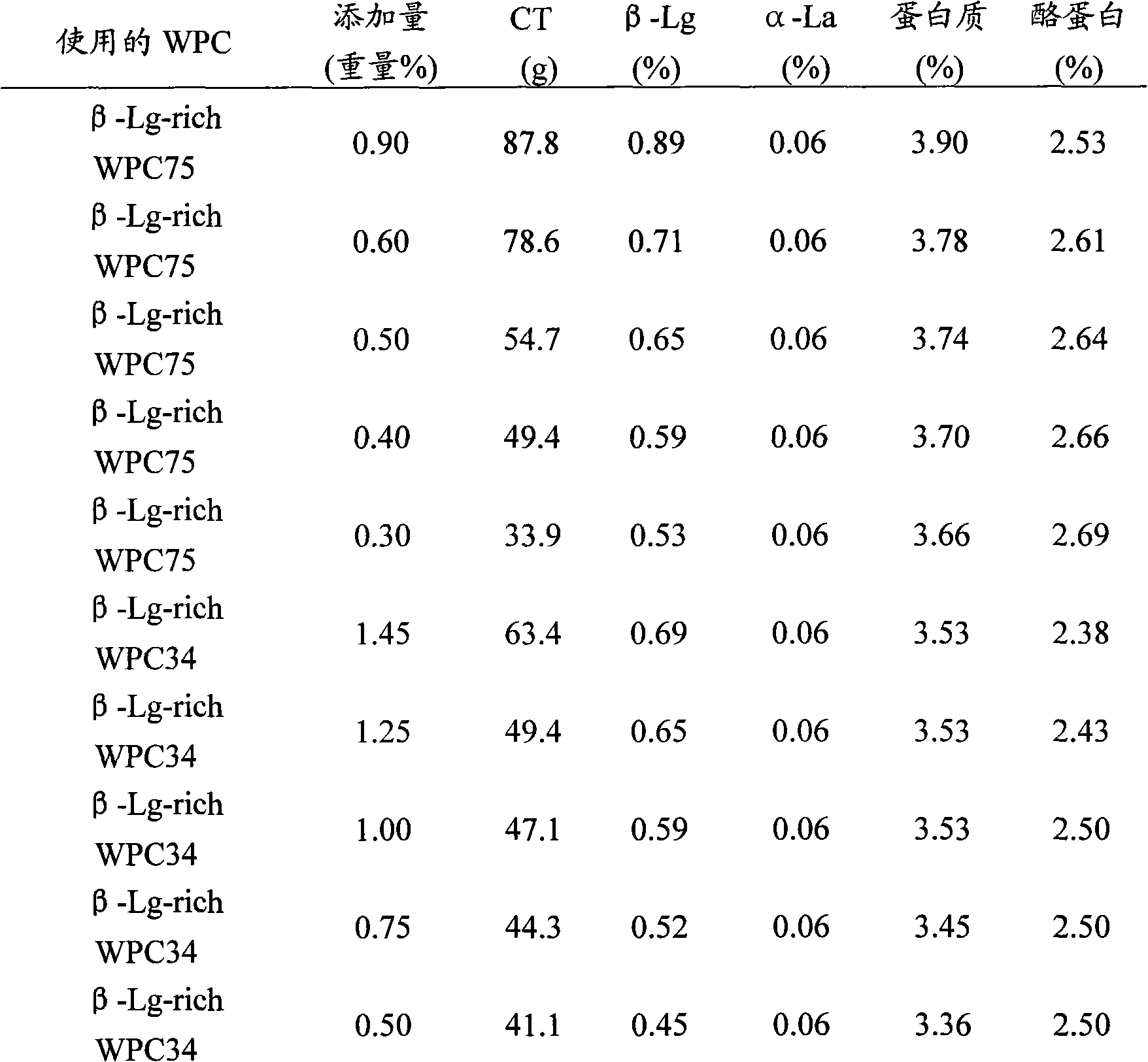

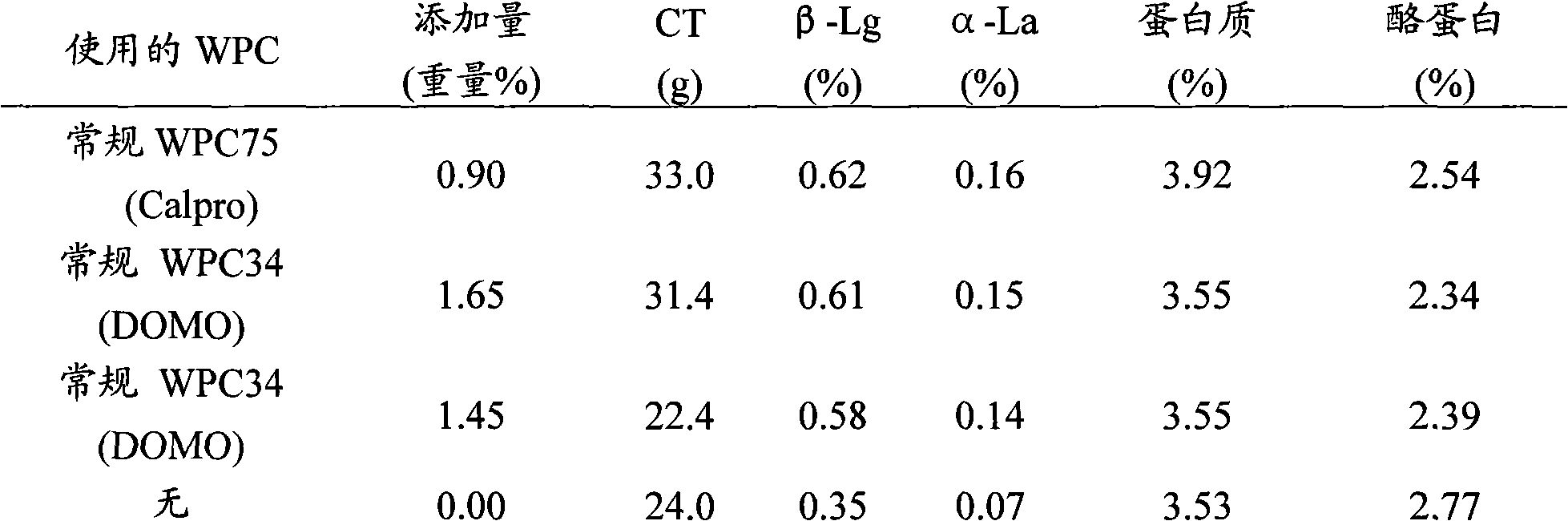

[0077] Example 1: Effect of β-Lg-rich WPC on physical properties of yogurt

[0078] In Example 1, the influence of β-Lg-enriched WPC on the physical properties of yogurt was examined. First, β-Lg-rich WPC (β-Lg-rich WPC75 or β-Lg-rich WPC34) manufactured by Friesland FoodDomo Inc. (Domo) and water were mixed with 77.5 kg of UHT sterilized milk and 2.9 kg of skim milk powder 17.6kg, to prepare the yogurt mix. It should be noted that the weight % of protein contained in β-Lg-richWPC75 was 75% by weight. On the other hand, the weight of protein contained in β-Lg-richWPC34 was 34% by weight. β-Lg-rich WPC75 and β-Lg-rich WPC34 were produced by adjusting the protein content to 75% by weight and 34% by weight with respect to the solid content, respectively. It should be noted that the amounts of milk, skim milk powder and water were adjusted so that the milk solids not fat (SNF) was 9.5% by weight of the total and the fat content was 3% by weight.

[0079] The yoghurt mixture wa...

Embodiment 2

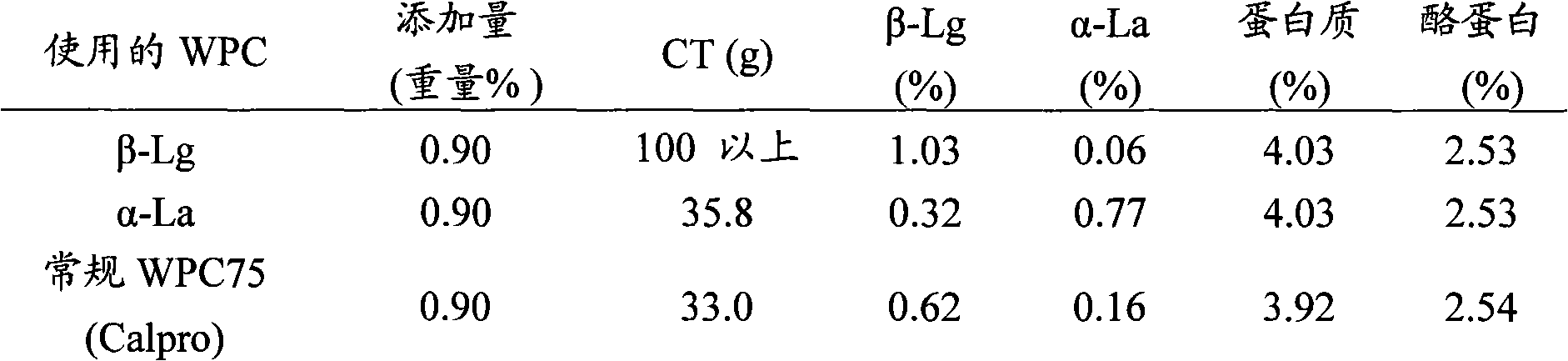

[0087] Example 2: Effects of β-Lg and α-La on Physical Properties of Yogurt

[0088] In Example 2, the effects of β-Lg and α-La on the physical properties of yogurt were examined. That is, when producing fermented milk, the β-Lg-rich WPC75 and β-Lg-rich WPC34 used in Example 1 were replaced with β-Lg and α-La manufactured by Davisco Inc. (DAVISCO), and the amounts added were 0.9 % by weight, except that, fermented milk was produced similarly to Example 1, and the curd strength (hardness) was measured. The results are shown in Table 3 below. In addition, the results of curd strength of fermented milk produced using conventional WPC (manufactured by Calpro, WPC75) are also shown in Table 3 as a control. It should be noted that the protein content of both β-Lg and α-La was 95% by weight, of which β-Lg or α-La accounted for 90% by weight. In addition, the addition amount (weight%) in Table 3 shows the weight% of the added β-Lg or α-La in the whole yoghurt mix.

[0089] Table 3...

Embodiment 3

[0092] Example 3: Sterilization conditions when using α-La-containing yogurt mix

[0093] In Example 3, the influence of the sterilization conditions at the time of using the yogurt mixture containing α-La on fermented milk was examined. When producing fermented milk, β-Lg-rich WPC75 and β-Lg-rich WPC34 used in Example 1 were replaced with α-La manufactured by Davisco Inc. (DAVISCO) in an amount of 0.9% by weight, and 95°C Fermented milk was produced and curd strength (hardness) was measured in the same manner as in Example 1, except that the high-temperature short-term sterilization treatment was replaced by ultra-high temperature sterilization treatment (120° C., 2 min) in an autoclave. . It should be noted that conventional WPC75 (manufactured by Calpro), was subjected to ultra-high temperature sterilization to produce fermented milk, and its curd strength was measured as a control group. The results are shown in Table 4 below.

[0094] Table 4: Curd strength of fermente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com