Return sludge separation technique for improving dephosphorization removing nitric efficiency factor of wastewater treatment

A technology for returning sludge and denitrification efficiency, which is applied in the field of returning sludge separation technology to achieve the effect of improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The implementation process of the present invention is described below

[0044] The experiment uses typical domestic sewage, and its main water quality indicators are as follows: pH is 7.3; COD is 250-400mg / L; BOD5 is 160-280mg / L; TN is 30-45mg / L; NH4+-N is 15-20mg / L ; NO3--N is 0.2mg / L; TP is 8-10mg / L; alkalinity is 380-440mg / L.

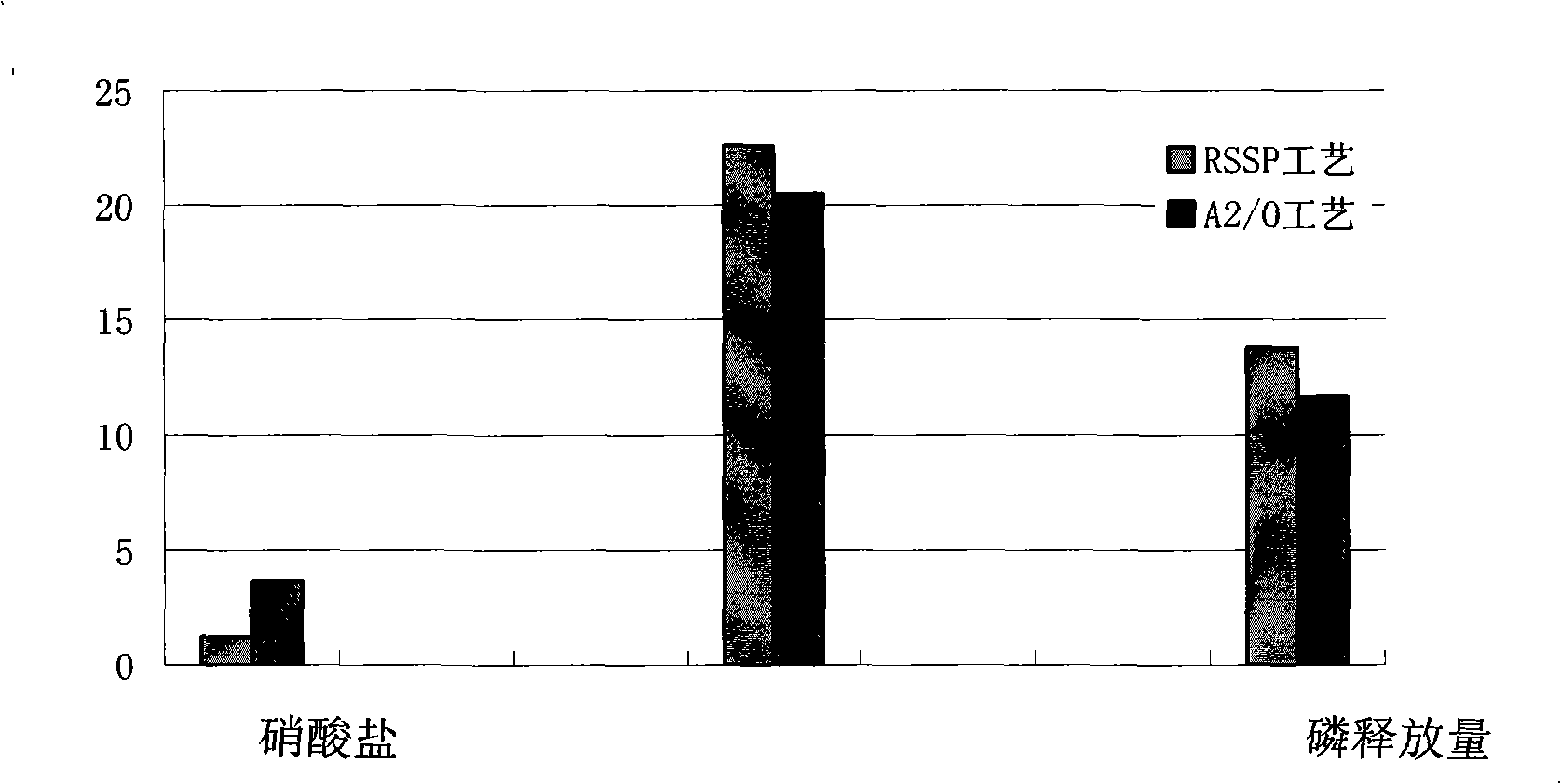

[0045] The return sludge separation process, abbreviated as RSSP (Return SludgeSeparate Process), was carried out at a scale of 0.5 cubic meters per day, and was compared with A 2 / O process for comparative study.

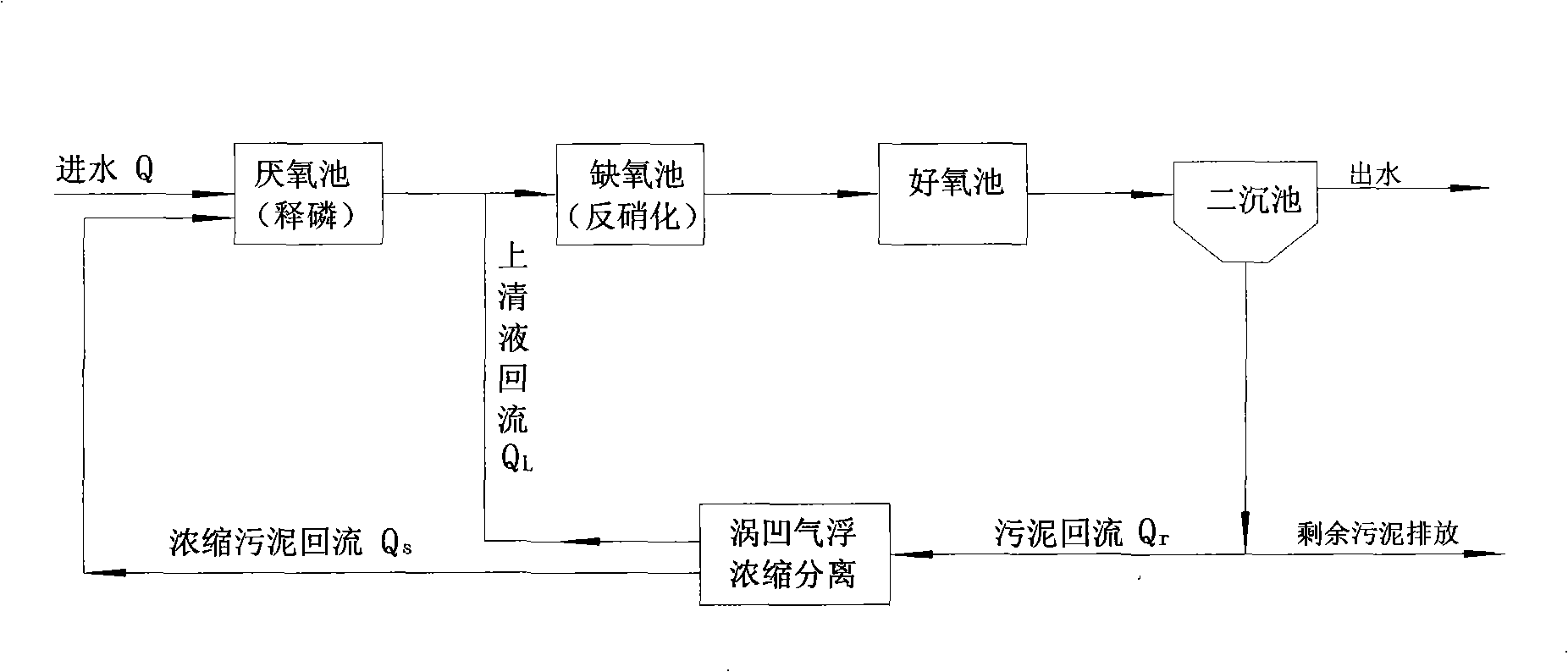

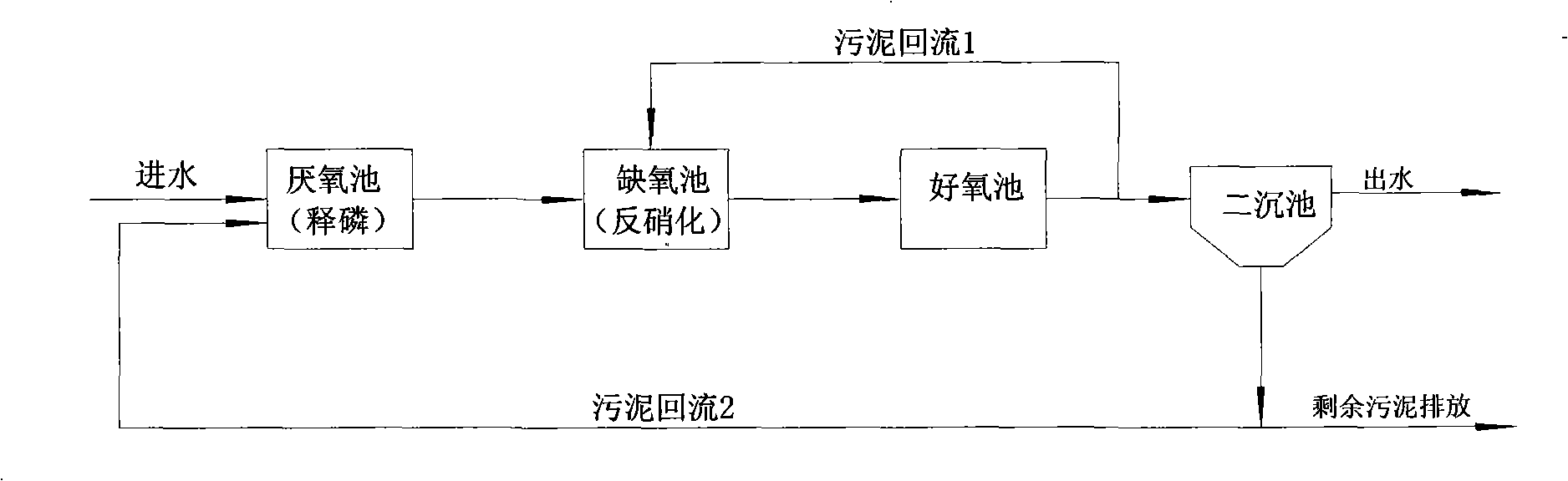

[0046] A 2 For the / O process, see Li Gendong, Diao Shushen. Discussion on biological phosphorus removal technology for wastewater, "Environmental Technology" 2005, Issue 1, 37-38. The main reaction zone is composed of anaerobic pool, anoxic pool and aerobic pool. The present invention improves the return sludge separation process (RSSP) of sewage treatment dephosphorization and denitrification efficiency, is in A 2 On the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com