Modeling method of moment-limited hydraulic coupler-driven complex mechanical system

A technology for hydraulic couplings and mechanical systems, which is applied in the fields of instrumentation, aerodynamic improvement, special data processing applications, etc., and can solve the problems of incomplete matching, neglect, affecting the accuracy, correctness and smooth implementation of complex mechanical systems. , to achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

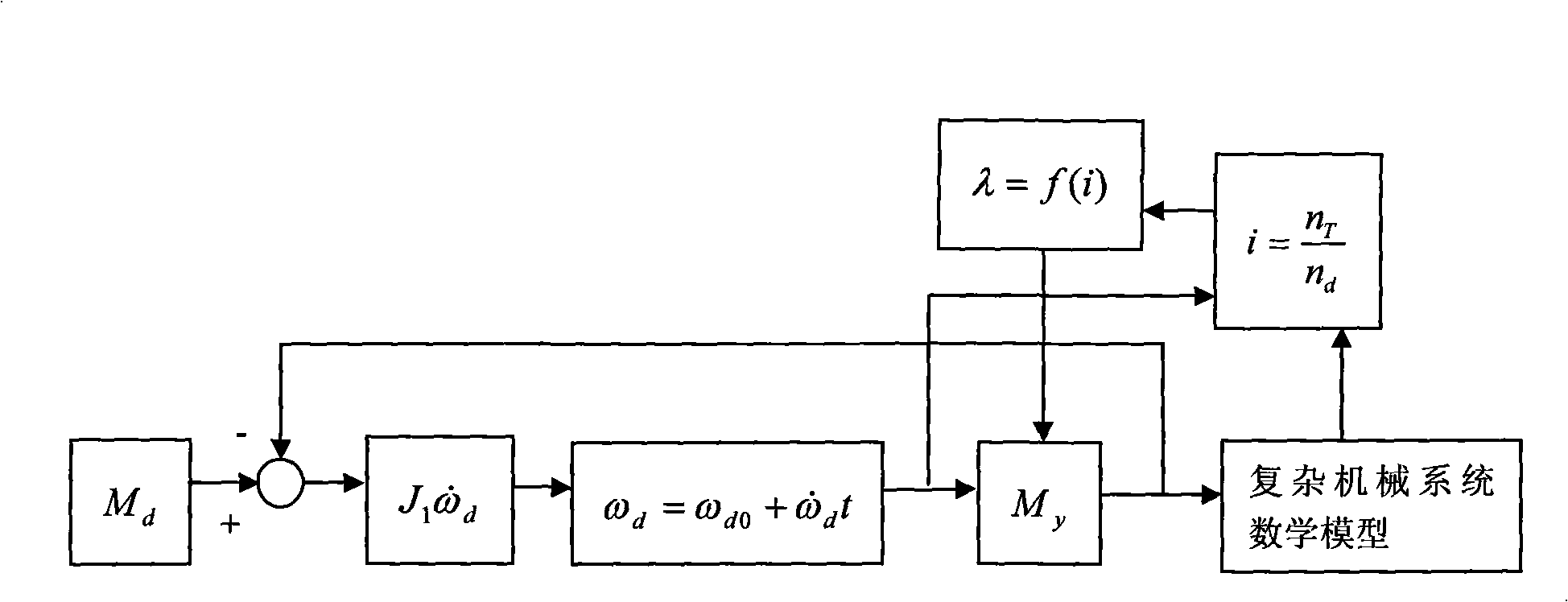

[0034] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0035] 1) First, in the initial stage, that is, when the motor is just energized, it generates the motor output torque M d ;

[0036] 2) Secondly, in the initial stage, the hydraulic coupling pump wheel has an initial output torque M y ;

[0037] 3) According to the formula M d - M y = J 1 ω · d and ω d = ω d 0 + ω · d Δt The angular acceleration, angular velocity and rotational speed of the motor and the pump wheel of the hydraulic coupling can be calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com