Convex point production method capable of preventing blue film

A fabrication method and bump technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as difficulty in removing blue film, and easy contamination of bumps made of lead and tin materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the method for manufacturing bumps that can avoid the blue film of the present invention will be further described in detail.

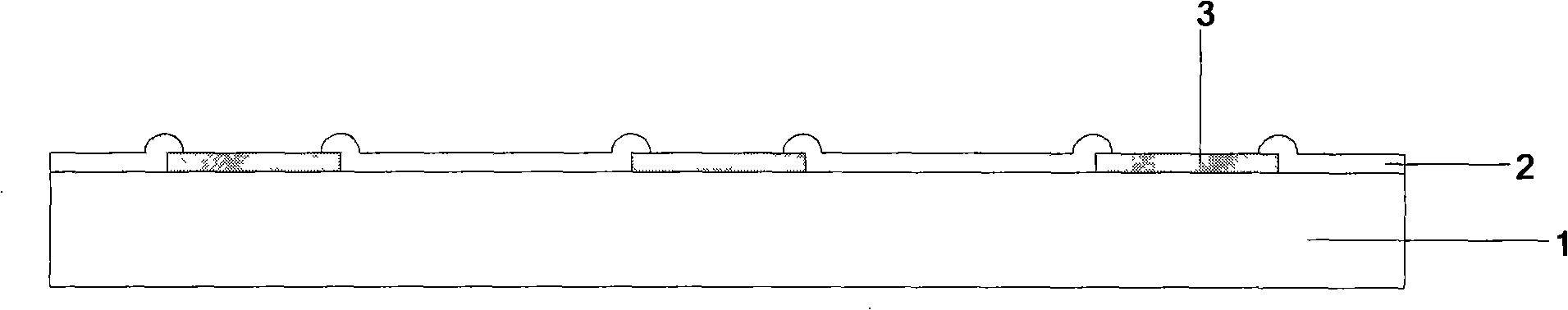

[0021] See figure 1 , Shows a cross-sectional view of a wafer using the present invention to avoid the blue film bump manufacturing method. As shown in the figure, a metal pad 2 and a passivation layer 3 are formed on the wafer 1.

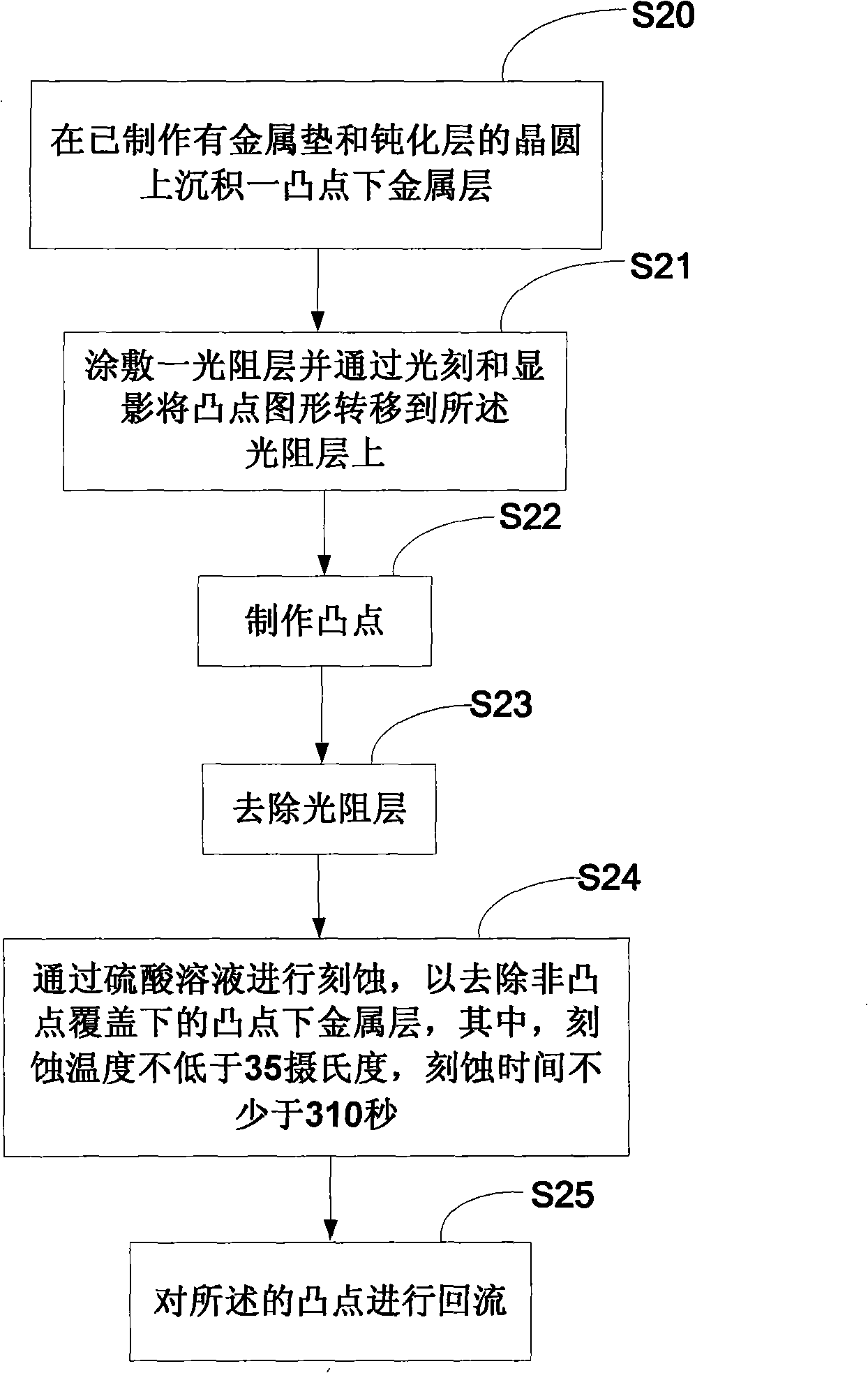

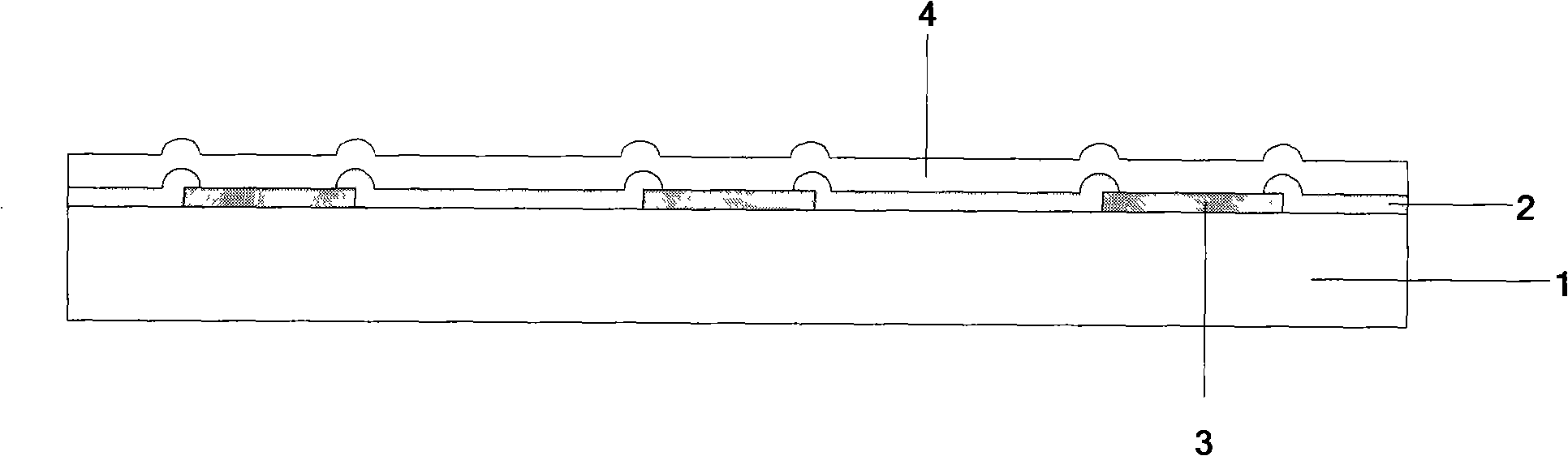

[0022] See figure 2 The method for manufacturing bumps that can avoid blue film of the present invention first proceeds to step S20 to deposit an under bump metal layer on the wafer on which the metal pad 2 and the passivation layer 3 have been fabricated. See image 3 , Showing the cross-sectional view of the wafer after step S20 is completed, refer to figure 1 As shown in the figure, the under-bump metal layer 4 is deposited on the metal pad 2 and the passivation layer 3.

[0023] Then continue to step S21, apply a photoresist layer and transfer the convex dot pattern to the photoresist layer by photol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com