High-frequency joint

A high-frequency and connector technology, applied in the field of high-frequency joints, can solve problems such as looseness, high torque value, and noise interference, and achieve the effects of preventing looseness and falling off, avoiding interference noise, and simple component processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

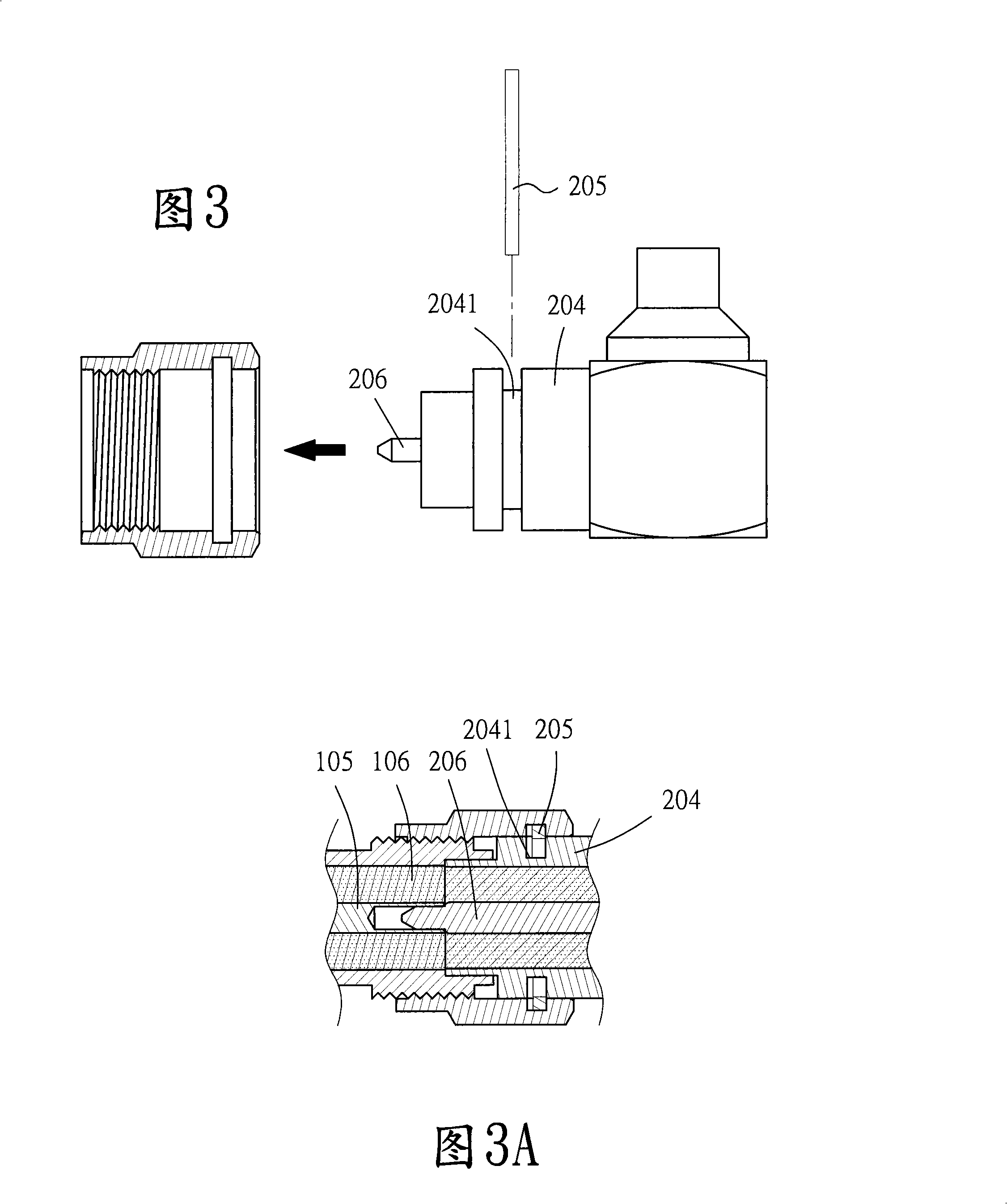

[0024] In order to illustrate the structure and the achieved effects of the present invention in detail, the following preferred embodiments are given below together with the accompanying drawings.

[0025] The high-frequency connector meter provided by the present invention, as shown in FIG. 8 and FIG. 9 , includes a first component 4 and a second component 9 . in:

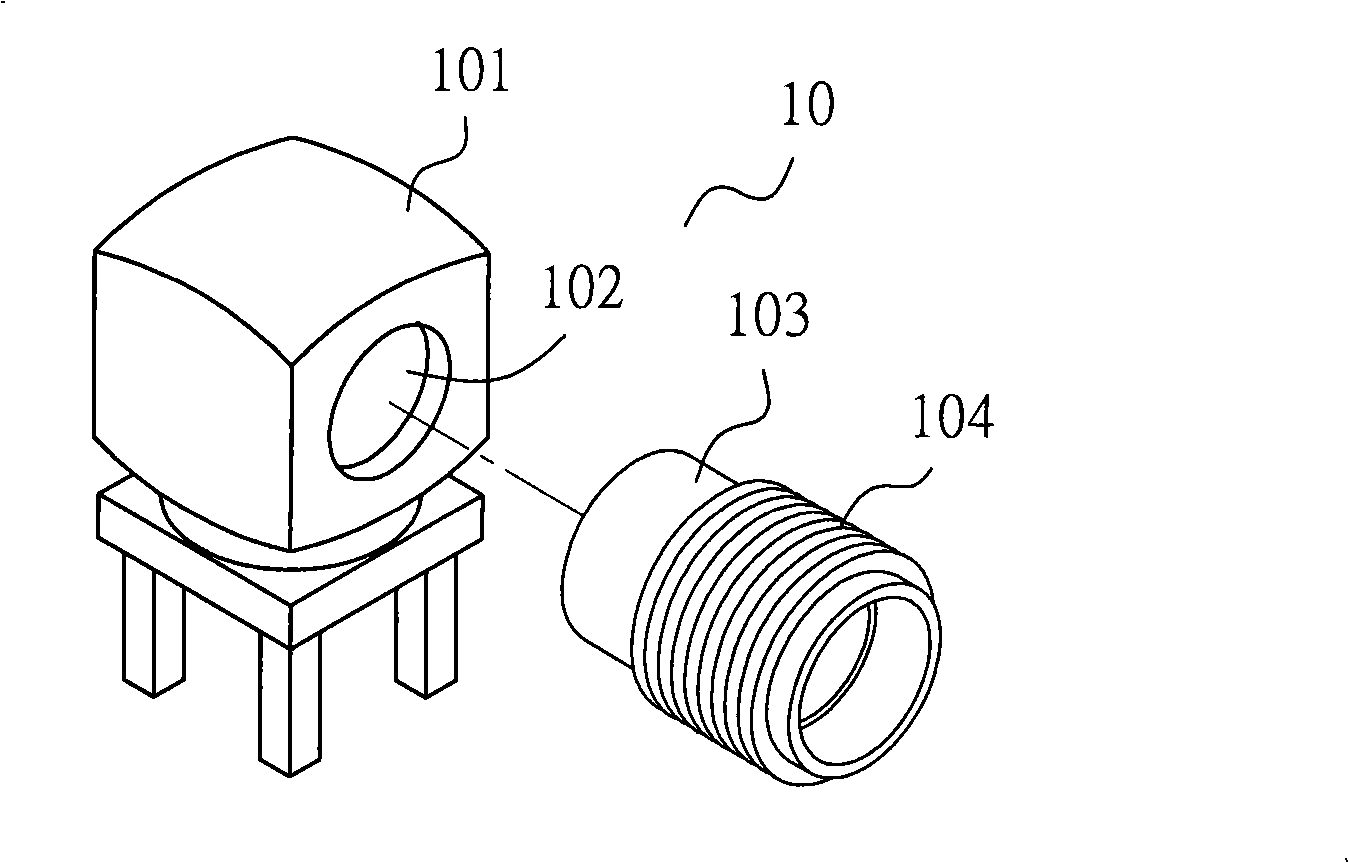

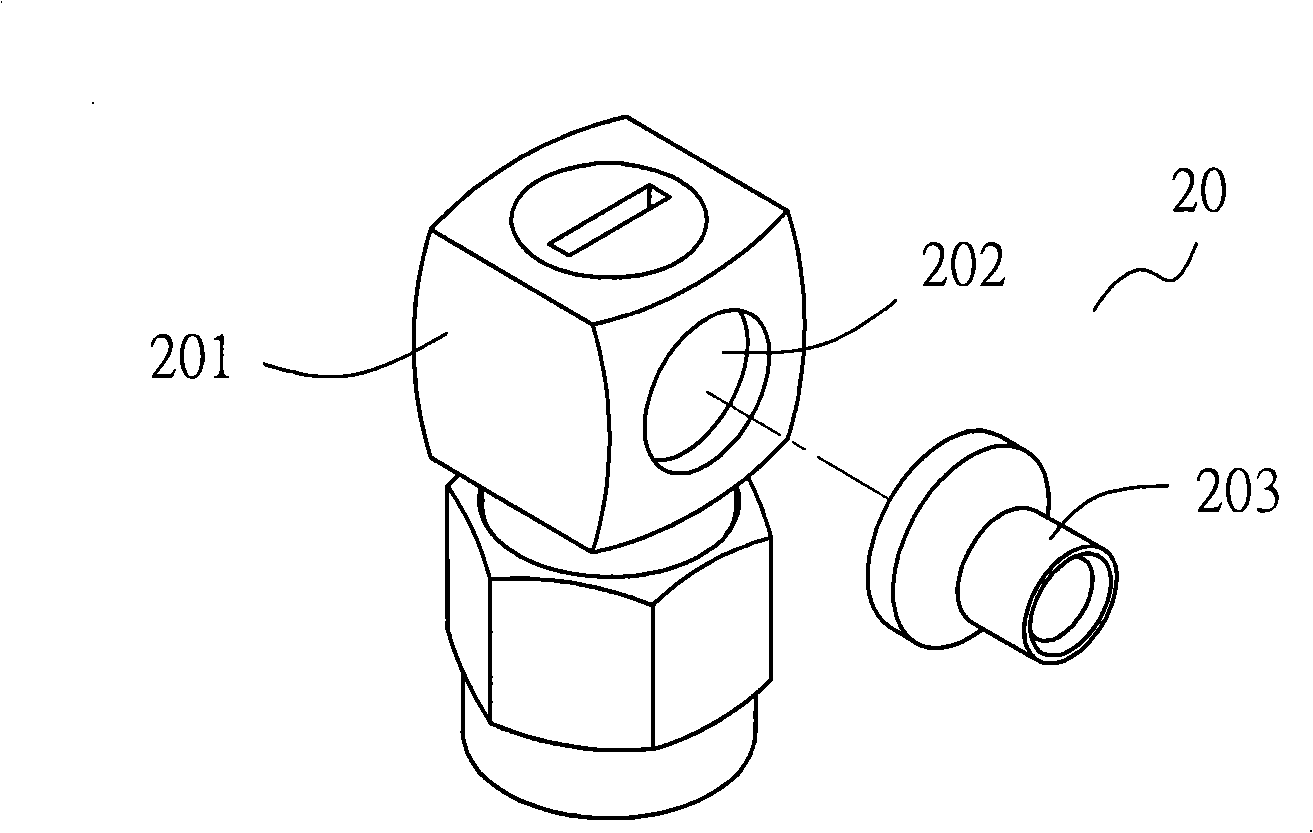

[0026] The first component 4, such as Figure 4 , Figure 5 As shown, it includes a connecting piece 1 with a through hole 11, a gap 12 is provided on one side of the connecting piece 1, an insulator 41 can be inserted in the through hole 11, and the notch 12 can make the connecting piece 1 and the joint 2 combine to increase the length. It can also cooperate with the L-shaped needle 3 to be inserted into the through hole 411 between the insulators 41, and can extend 90° through the horizontal section 21 between the joints 2, so the connecting piece 1 and the joint 2 will not rotate. An insulator 43 and a posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com