Ring shaped resonance cavity laser

A ring resonator and laser technology, applied in the field of lasers, can solve the problems of high installation accuracy, inability to produce on a large scale, and high manufacturing costs, and achieve the effects of low processing difficulty, convenience for large-scale production and application, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

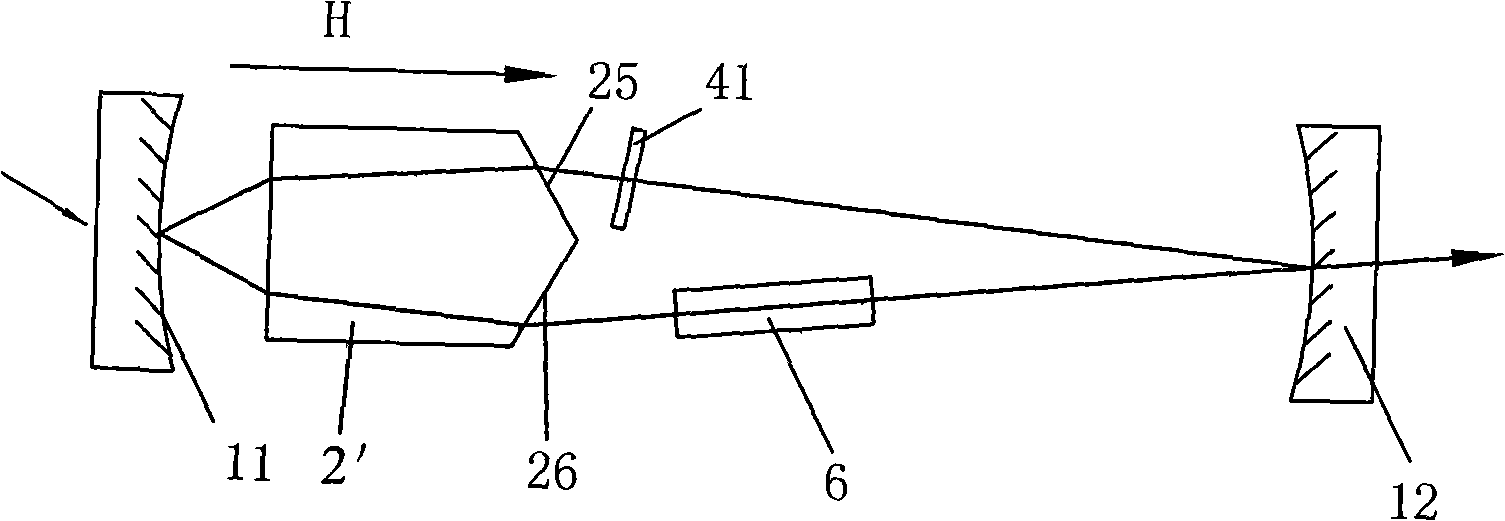

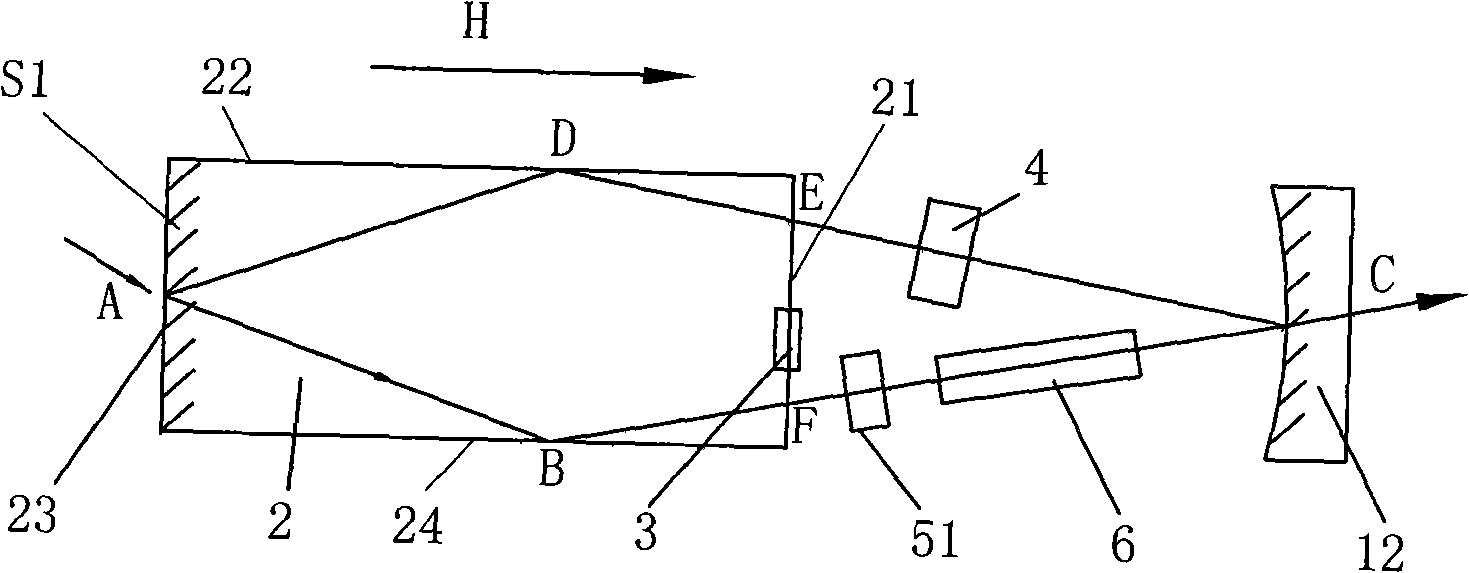

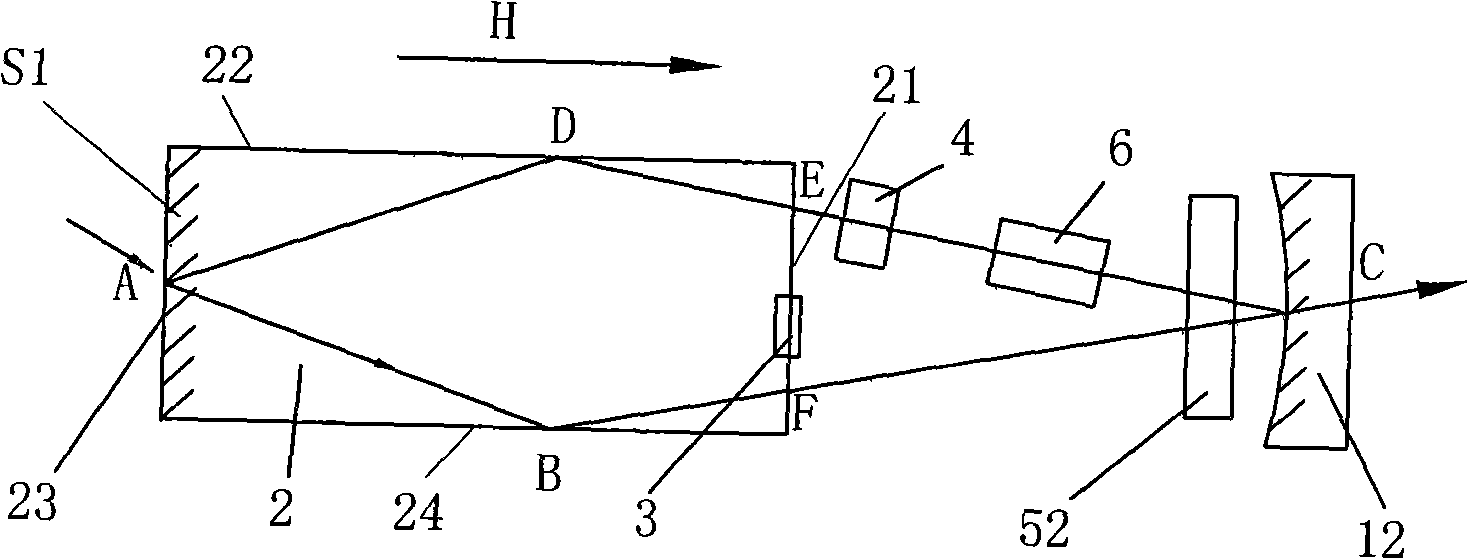

[0025] Please refer to figure 2 Or as shown in 3, the ring resonator laser of the present invention includes a rear cavity mirror 12 and a laser gain medium 2 with a magneto-optical rotation effect to form a ring optical path, and the laser gain medium 2 with a magneto-optical rotation effect is arranged in a magnetic field H, and the magnetic field H can be formed by a permanent magnets or electromagnets are provided. It is provided with an incident and outgoing end face 21 and three reflective surfaces 22, 23, 24, and the incident and outgoing end face 21 is centered with a light path blocking material 3, such as a non-optical surface, a film optical absorber or a hole, etc. Stop light from traveling vertically. Its reflective surface 23 facing back cavity mirror 12 is plated with high reflection film S1, and polarizing polarizer 4 and wave plate are located in the annular light path, as Figure 8 , 9 , 10, 11 or 12, the polarizing polarizer 4 can use Brewster plate 41, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com