Method for realizing digital control grinding roller curve by NC programming

A grinding and curve technology, applied in the direction of grinding machine parts, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc., can solve complex mechanical mechanisms, complex programming, and inaccurate adjustment of grinding curves. and other problems, to achieve the effect of simplifying the mechanical transmission structure, eliminating the tedious operation, and optimizing the development of special functions for the grinder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific embodiment:

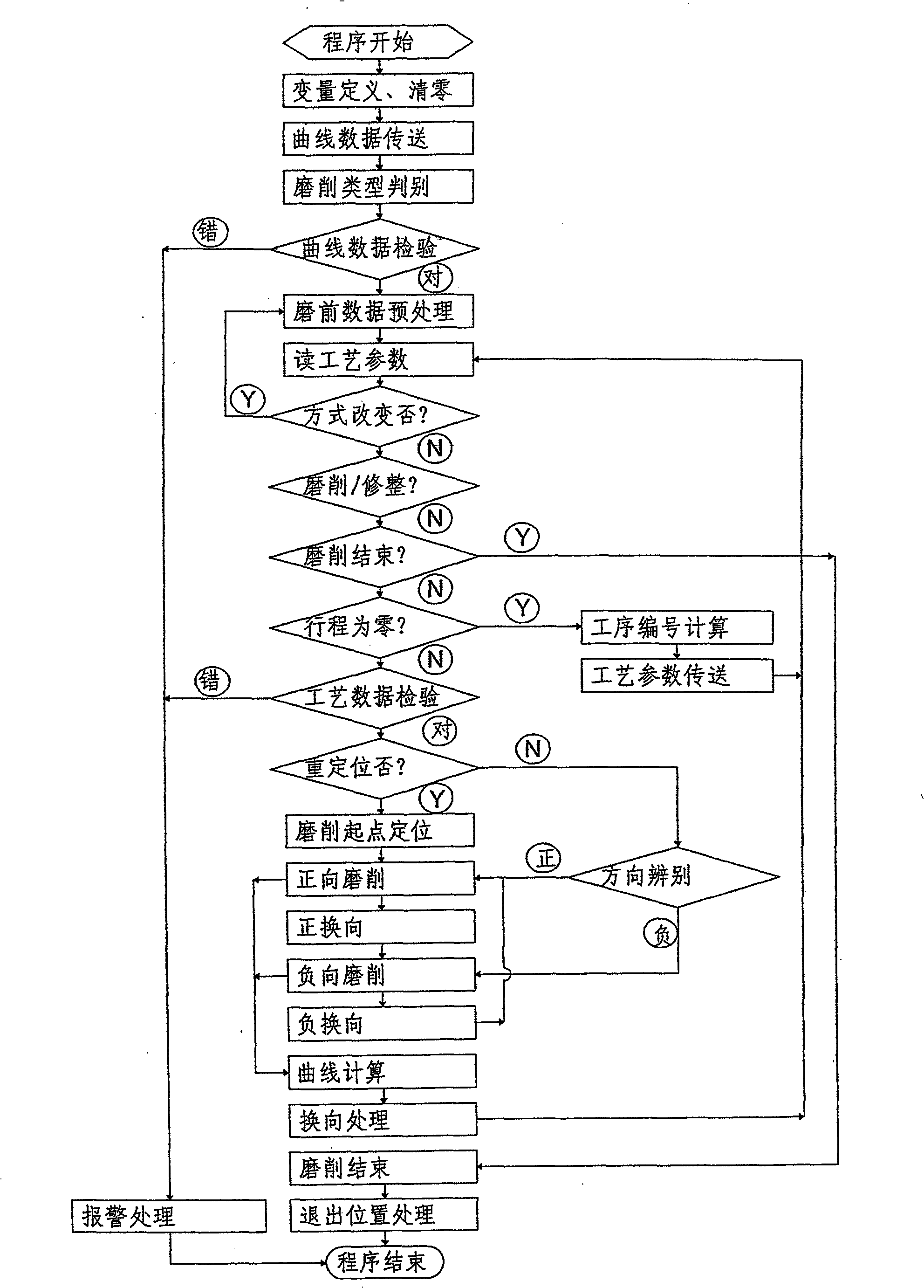

[0035] Such as figure 1 As shown, the specific steps are as follows:

[0036] 1) At the beginning of the program, use the R parameter table to input the characteristic parameters of the roll and the grinding process parameters, select the AUTO mode, press the start button to start the main grinding program, and call the main grinding subroutine; wherein, the R parameter table is:

[0037] R0~R9: current grinding process parameters

[0038] R0-----current process number, range: 0~9

[0039] R1-----current carriage speed, range: 0~4000mm / min

[0040] R2-----current continuous compensation, range: 0~1.2mm / min

[0041] R3-----current cycle feed, range: 0~0.12mm / time

[0042] R4-----current trip times, range: 0~100 times

[0043] R9-----Current process combination, range: 00000~099999999, each bit 0~9

[0044] R10~R19: current grinding curve parameters

[0045] R10-----Cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com