Construction method of micro point array in microchannel

A construction method and micro-channel technology, which are applied in the field of processing of micro-channels and their internal micro-dot arrays to achieve the direct effect of patterning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

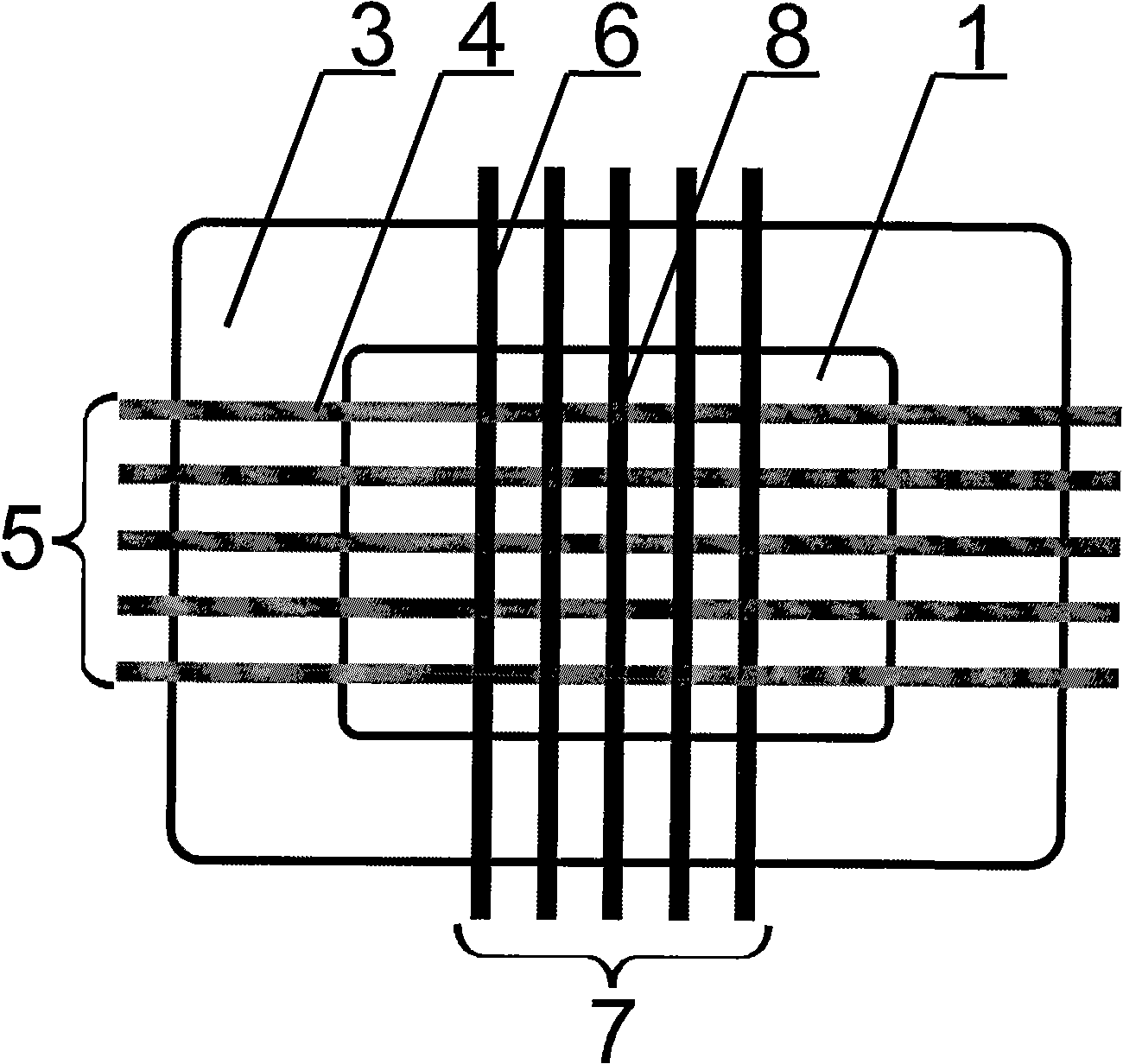

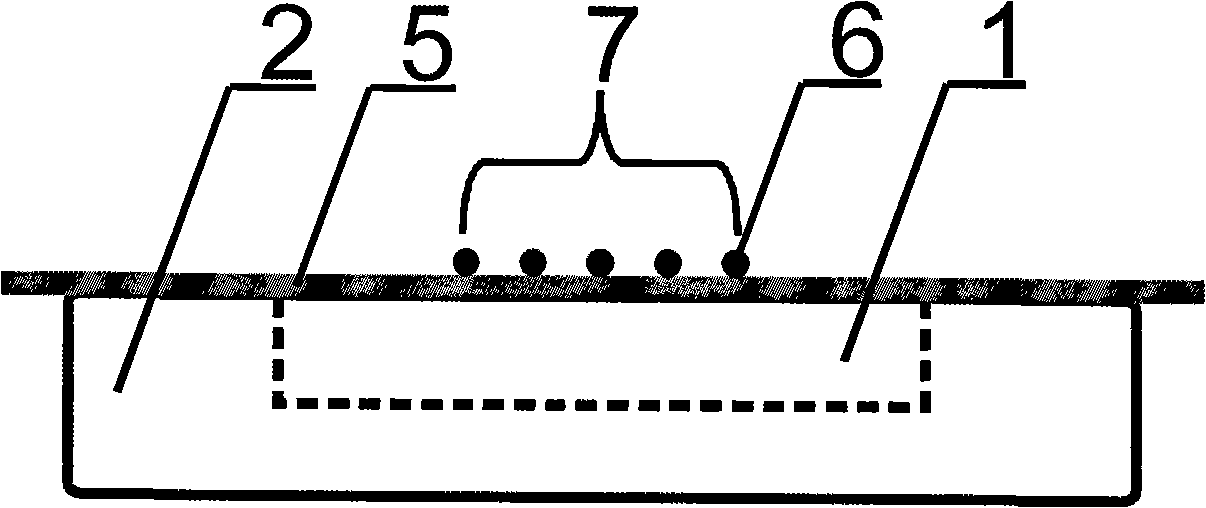

[0036] Such as Figure 1 to Figure 6 As shown, the process of constructing the micro-dot array in the planar micro-channel array according to the method of the present invention is described. The specific instructions are as follows:

[0037] The first step, cross wiring: such as figure 1 and figure 2 As shown, on the upper surface 3 of the substrate 2 with the recessed structure 1 in the center, the first kind of microwires 4 are arranged and fixed with a pitch of 90 microns along one direction to form the first microwire array 5, and the first microwire arrays 5 are arranged along the other direction. The second type of microwire 6 is laid out to form the second microwire array 7; the first microwire array 5 and the second microwire array 7 are intersected in pairs, and each intersection has a contact point 8. Then, press the cover sheet 10 with the through hole 9 in the center on the upper surface 3 of the base 2, so that the crossed first microwires formed by the first...

Embodiment 2

[0045] Such as Figure 7 As shown, this figure has described the micro-dot array in the single microchannel that is made by technical approach of the present invention. On the plexiglass substrate 2 upper surface 3 with rectangular groove (or recessed structure 1), arrange the nylon silk thread (as the II microfilament 6) of a diameter 40 microns along one direction and fix, on the other Dozens of platinum wires with a diameter of 20 microns (as the first kind of microwire 4) are arranged in parallel with a 10 micron pitch in the direction and fixed, and then the rectangular channel with the same size as the above-mentioned rectangular groove (or recessed structure 1) is passed The plexiglass cover sheet 10 of the hole 9 is covered on the base 2 and the groove 1 is aligned with the through hole 2 for fixing.

[0046] Proportion PDMS prepolymer and curing agent in a weight ratio of 10:1, mix evenly, place in a vacuum pump tank for about 40 minutes to remove the air in the poly...

Embodiment 3

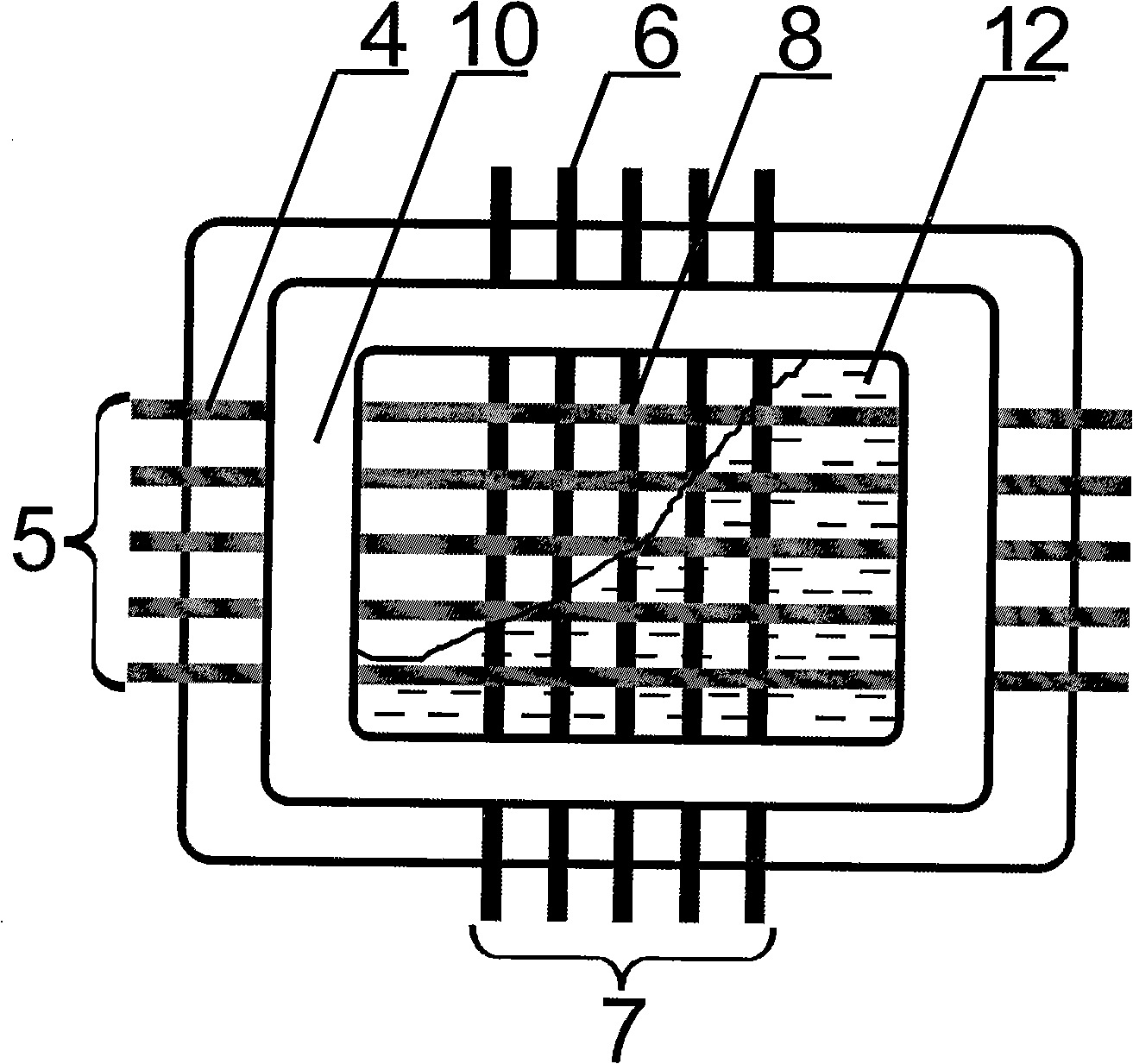

[0049] Such as Figure 8 and Figure 9As shown, the two figures describe the processing and formation of rectangular micro-dot arrays in micro-channels according to the technical approach of the present invention. Take stainless steel microwires with the same rectangular cross-section (i.e. the first microwire 4 and the second microwire 6), arrange them in an orthogonal array (i.e. form the first microwire array 5 and the second microwire array 7) and arrange them Fix it on the plexiglass substrate 2; take the cover sheet 10 and align it with the corresponding concave part on the substrate 2 and fix it, pour PDMS, and solidify, such as Figure 8 Shown in; After solidification, take out the II microwire array 7 arranged on top, promptly form the microdot array 15 in the microchannel 14, the shape of its point is a rectangle, and the length is the length of the I microwire 4 arranged below Width, the width is the width of the second kind of microfilament 6 arranged on top, as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com