Novel wastes incineration flue gas purification system and process thereof

A technology for incineration of flue gas and purification process, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as damage to the atmospheric environment, shortened service life, waste of activated carbon or slaked lime, etc., to improve purification capacity, ensure thorough purification, The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

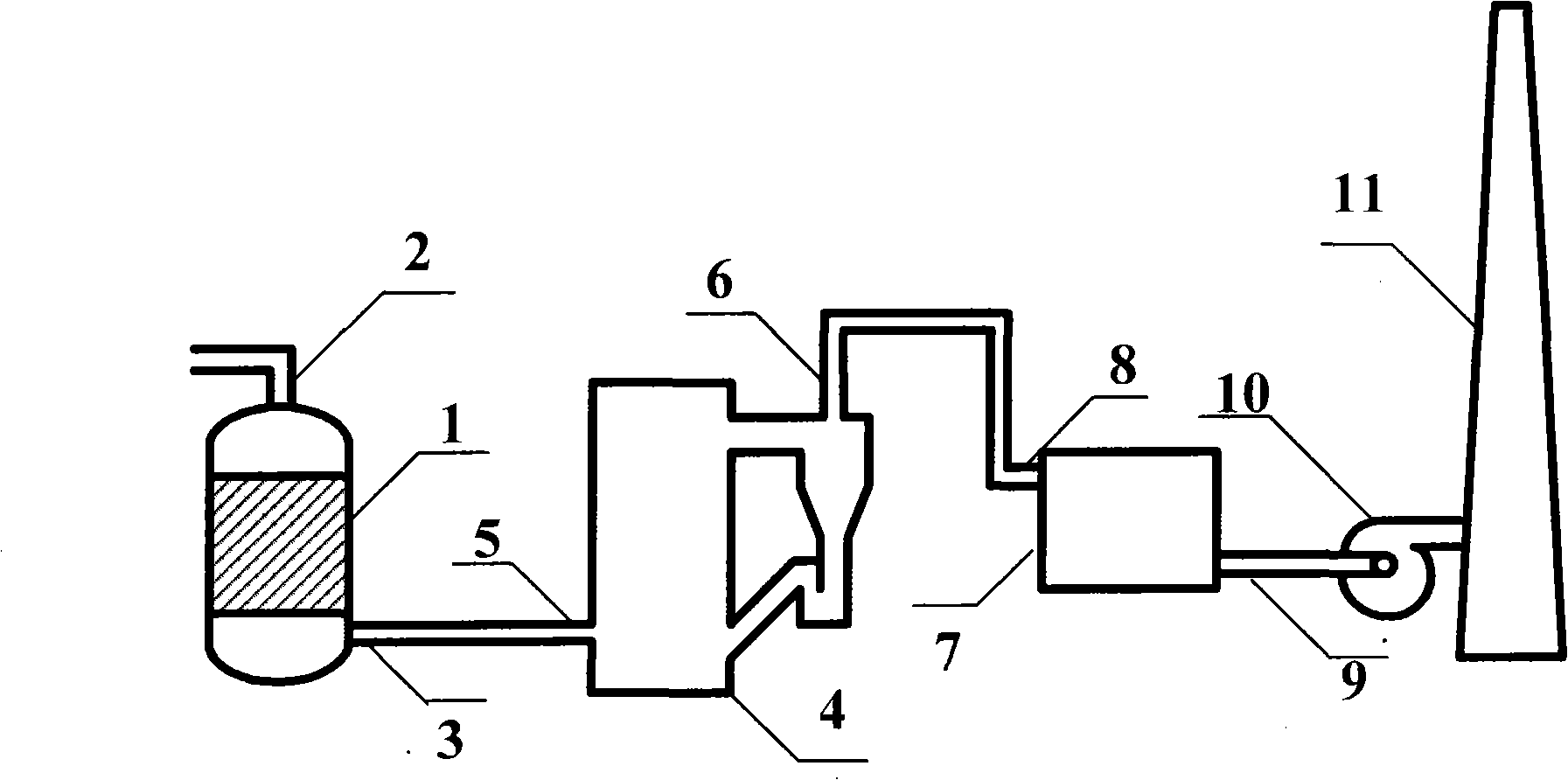

[0020] refer to figure 1 , the system is mainly composed of a semi-dry scrubber 1, a circulating fluidized bed 4, a bag filter 7 and a fan 10.

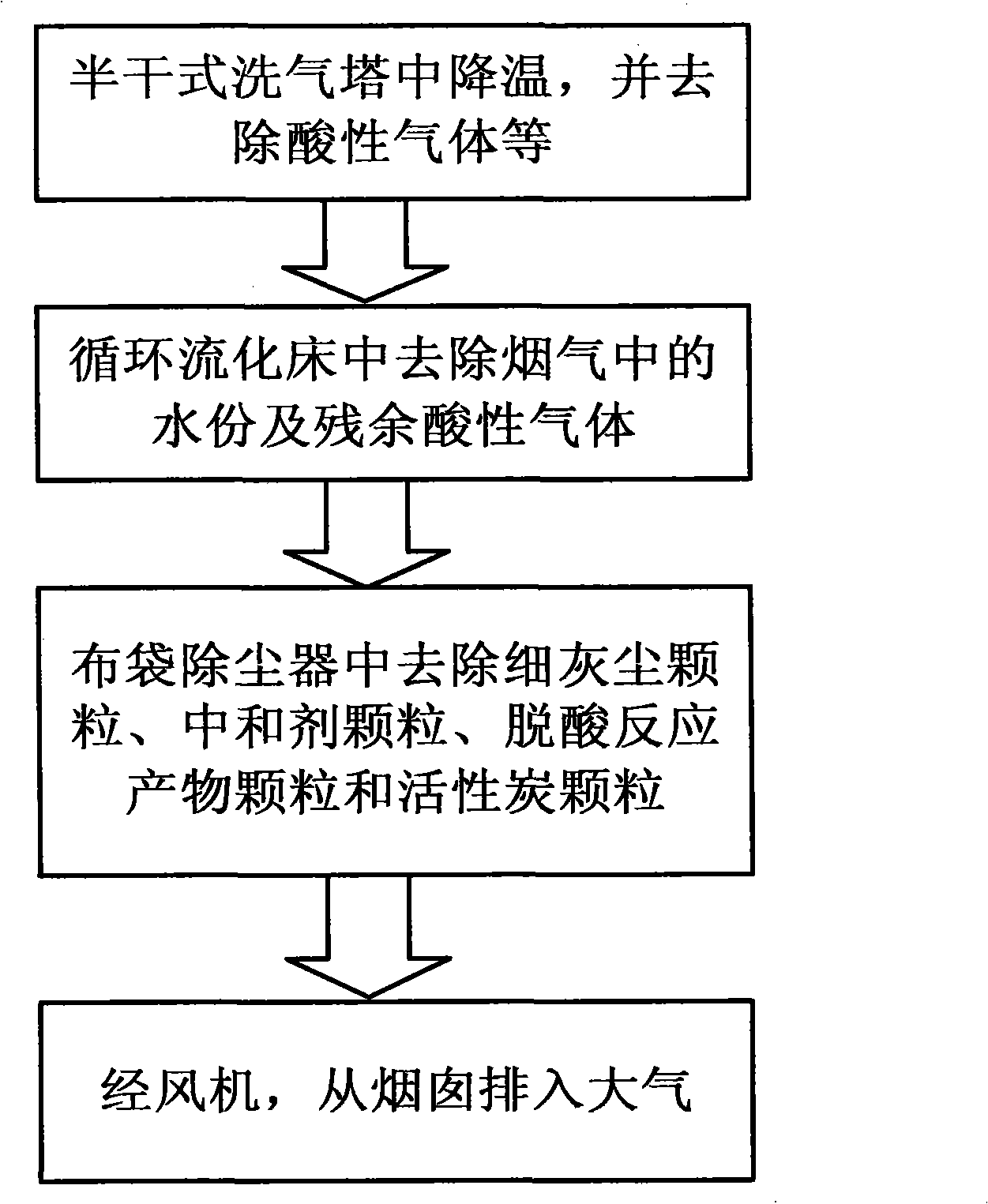

[0021] refer to figure 1 , figure 2 , the flue gas enters from the flue gas inlet 2 at the top of the semi-dry scrubber 1, and the slaked lime slurry is sprayed into the semi-dry scrubber 1 from the bottom of the tower upwards or downwards from the top of the tower, and is simultaneously sprayed by the internal high-efficiency atomizer Atomization makes it fully contact with high-temperature flue gas and produces neutralization effect, removes acid gas in flue gas, and rapidly cools flue gas. The flue gas temperature can be lowered below 200°C to prevent the regeneration of dioxins.

[0022] The flue gas enters the circulating fluidized bed 4 after coming out of the semi-dry scrubber 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com