Printing system, printing method and method for printing thin-film transistor and RLC circuit

A printing head and inkjet printing technology, which is applied in the fields of printed circuit, printed circuit manufacturing, circuit, etc., can solve problems such as difficulty in printing and forming, and achieve the effect of reliable printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

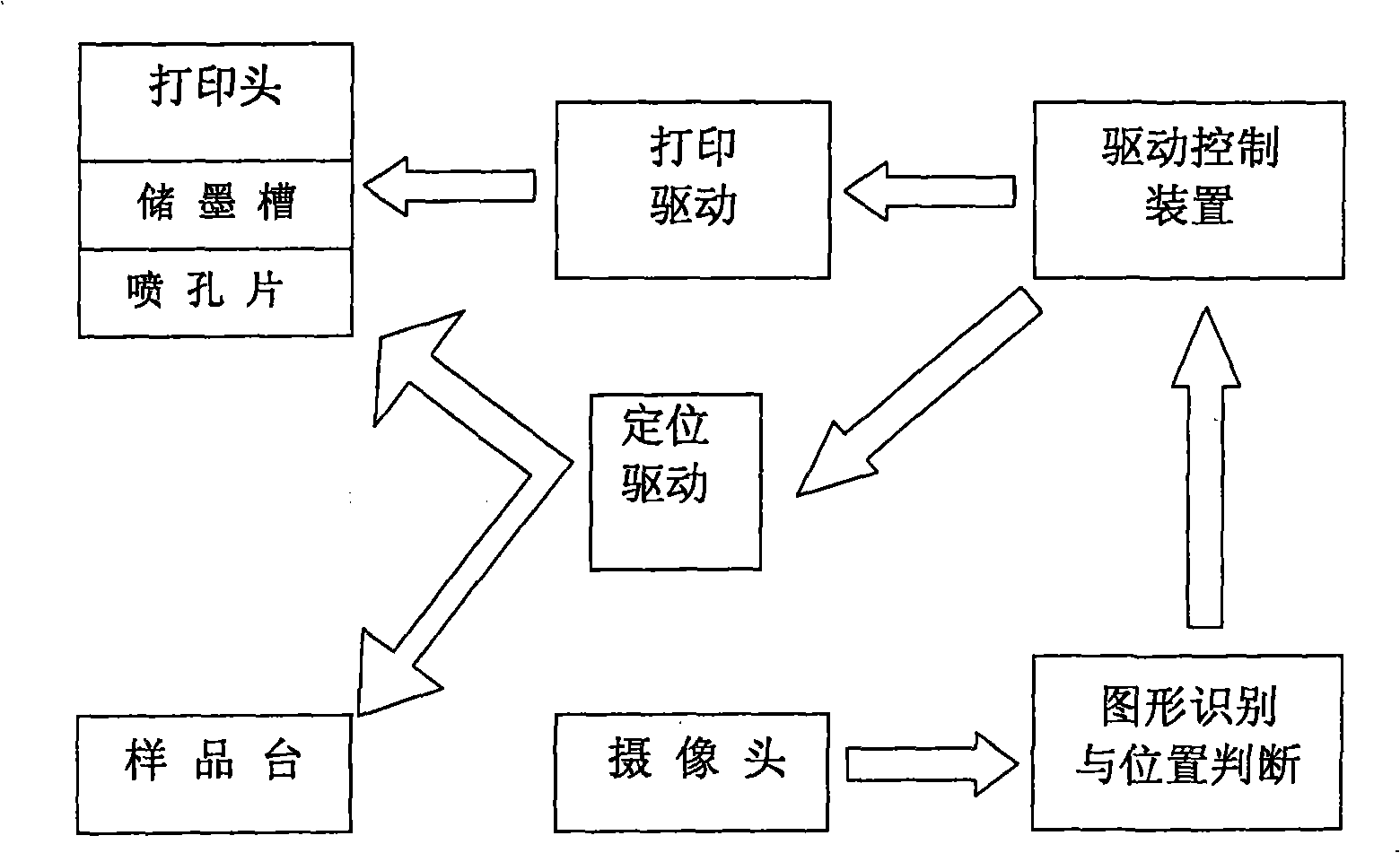

[0033] Embodiment 1 inkjet printing system

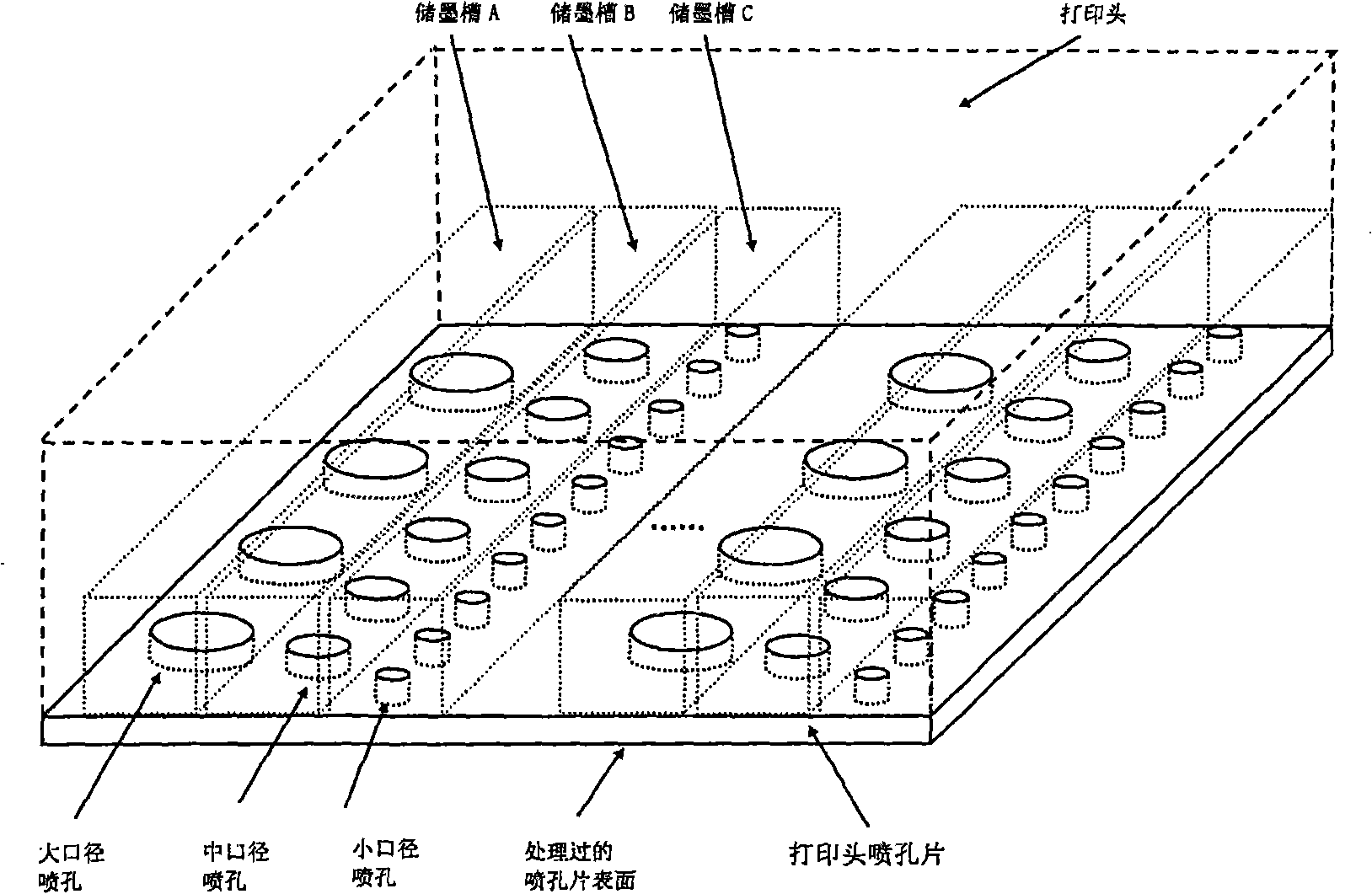

[0034] In order to solve the problems existing in the prior art, the present invention proposes a novel printing system of multi-aperture synthesis. In order to facilitate the understanding of the present invention, the existing inkjet printing system is briefly described here.

[0035] Figure 1a Shown is a schematic diagram of an existing inkjet printing system, Figure 1a The system includes:

[0036] sample stage;

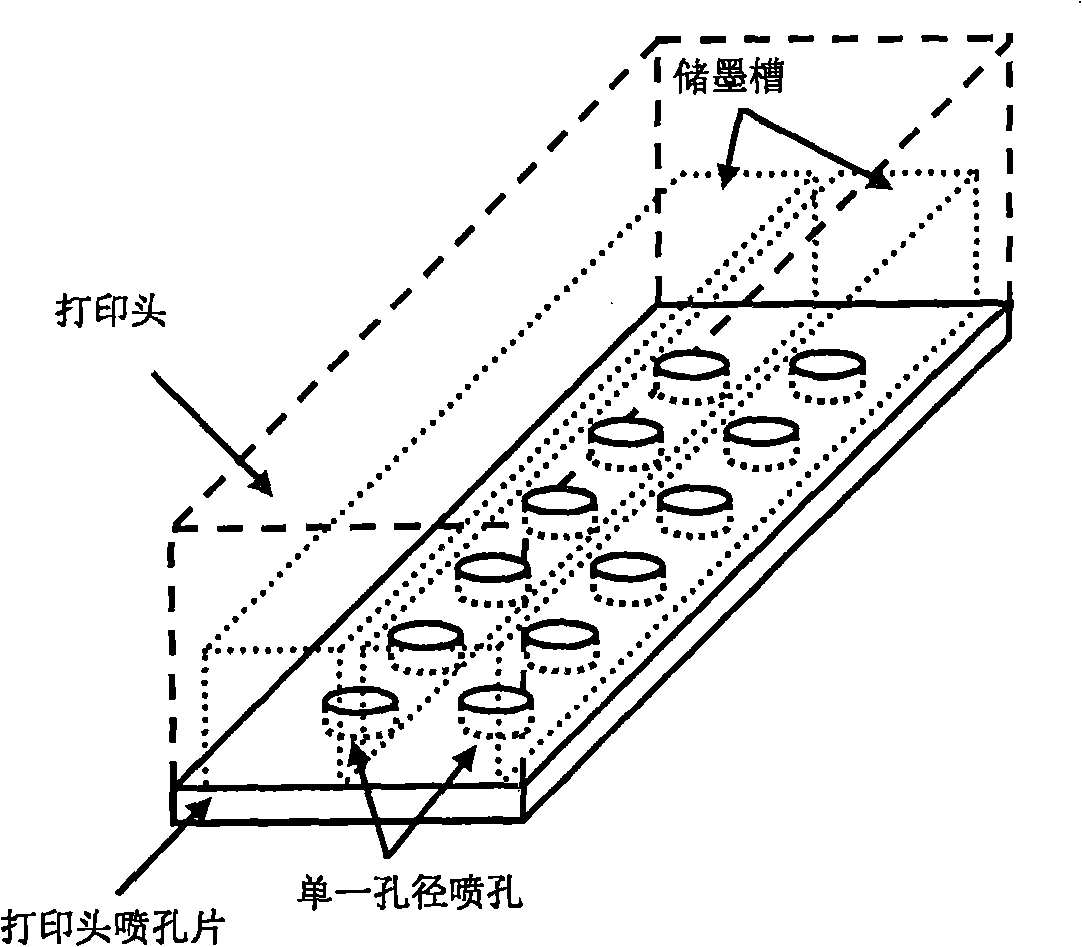

[0037] A printhead that includes ink reservoirs and orifice sheets, such as Figure 1b shown. The orifice sheet is provided with orifices of the same diameter, and each orifice can be driven independently for printing operation.

[0038] A printing driving device, used to drive the nozzle holes of the printing head to perform printing operation, the printing driving device may be, for example, a waveform generator;

[0039] The positioning driving device is used to drive the printing head or the sample stage to ...

Embodiment 2

[0056] Embodiment 2 carries out the method for inkjet printing

[0057] Traditional semiconductors are manufactured on silicon wafers, so they are also called silicon-based manufacturing. Semiconductor manufacturing technology is divided into front-end and back-end process parts. The front-end process flow includes deposition, removal, circuit routing and electrical property adjustment; the back-end process flow includes heat treatment and packaging technology. Most current fabrication of organic transistors is based on the fabrication process of silicon-based semiconductors. The specific process is: design the drain and source of the semiconductor device and circuit wiring, and make it into a mold. Coating photoresist on the surface of the base body, using photoetching technology in conjunction with the use of the mold, forming on the photoresist film. Then, it is placed in an evaporator, and the conductive metal is melted at high temperature to form a gaseous metal, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com