Four-phase solid-liquid separation method for well drilling wastes

A drilling waste, solid-liquid separation technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve problems such as groundwater pollution, COD, and difficulty in chromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

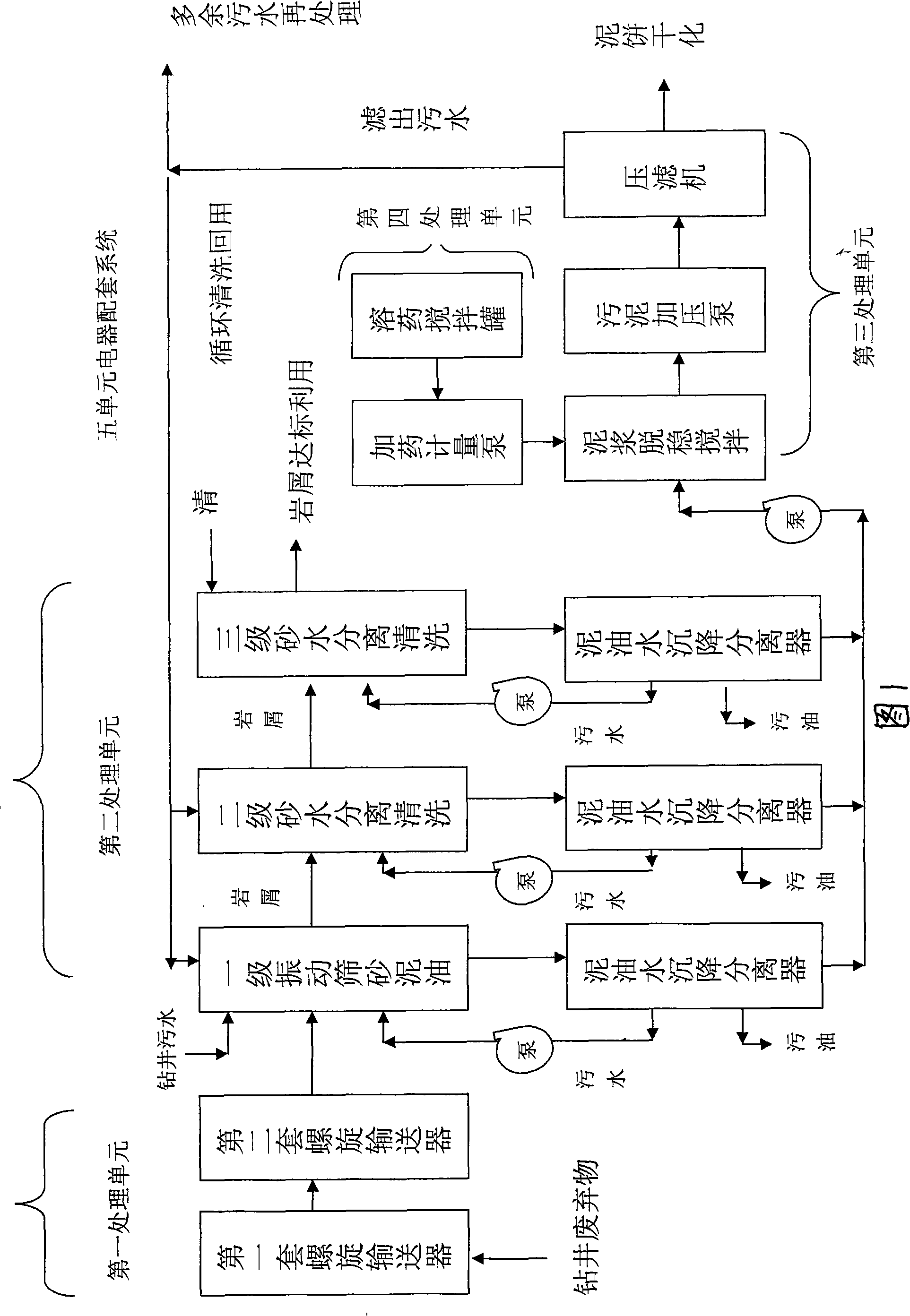

[0014] The present invention adopts pre-control, aims at eliminating the pollution of the drilling mud pool and reducing land occupation, and realizes that the drilling waste returned from the wellhead can be treated while drilling before landing, and the waste mud in the waste mud pool can also be diluted before to process. The principle of the process is that according to the different particle sizes and properties of the drilling waste, the cuttings are washed and separated in sequence, the settled sludge is pressed into a mud cake, the filtrate is formed into sewage, and the floating waste oil is automatically overflowed and discharged, so that the drilling waste is formed. The four phases are separated, creating conditions for subsequent classification, reprocessing and comprehensive utilization, so as to meet the environmental protection requirements of drilling waste not falling to the ground.

[0015] The process of the solid-liquid separation device for drilling waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com