Polarizing plate having optical compensation layer, liquid crystal panel using the polarizing plate having optical compensation layer, liquid crystal display device, and image display device

An optical compensation layer, liquid crystal panel technology, applied in the directions of optics, optical elements, polarizing elements, etc., can solve the problems of white turbidity of retardation film, damage of retardation film, cumbersome quality management, etc., achieve high contrast, achieve contrast, inhibit The effect of color shift

Inactive Publication Date: 2008-10-15

NITTO DENKO CORP

View PDF26 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in this laminated retardation layer, since the liquid crystal monomer is dissolved in an organic solvent and directly coated on the retardation film, the retardation film will be corroded by the organic solvent, resulting in damage to the retardation film. , leading to the problem of white turbidity in the retardation film

In addition, when forming a phase difference layer composed of a liquid crystal layer by coating, since the phase difference in the thickness direction is controlled by the thickness of the coating film after drying, it is necessary to control the thickness of the coating film with high precision, and It is necessary to pay attention to the problem that the quality control in the work process such as air bubbles or foreign matter mixed into the coating film is cumbersome, resulting in a decrease in the yield of manufacturing.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

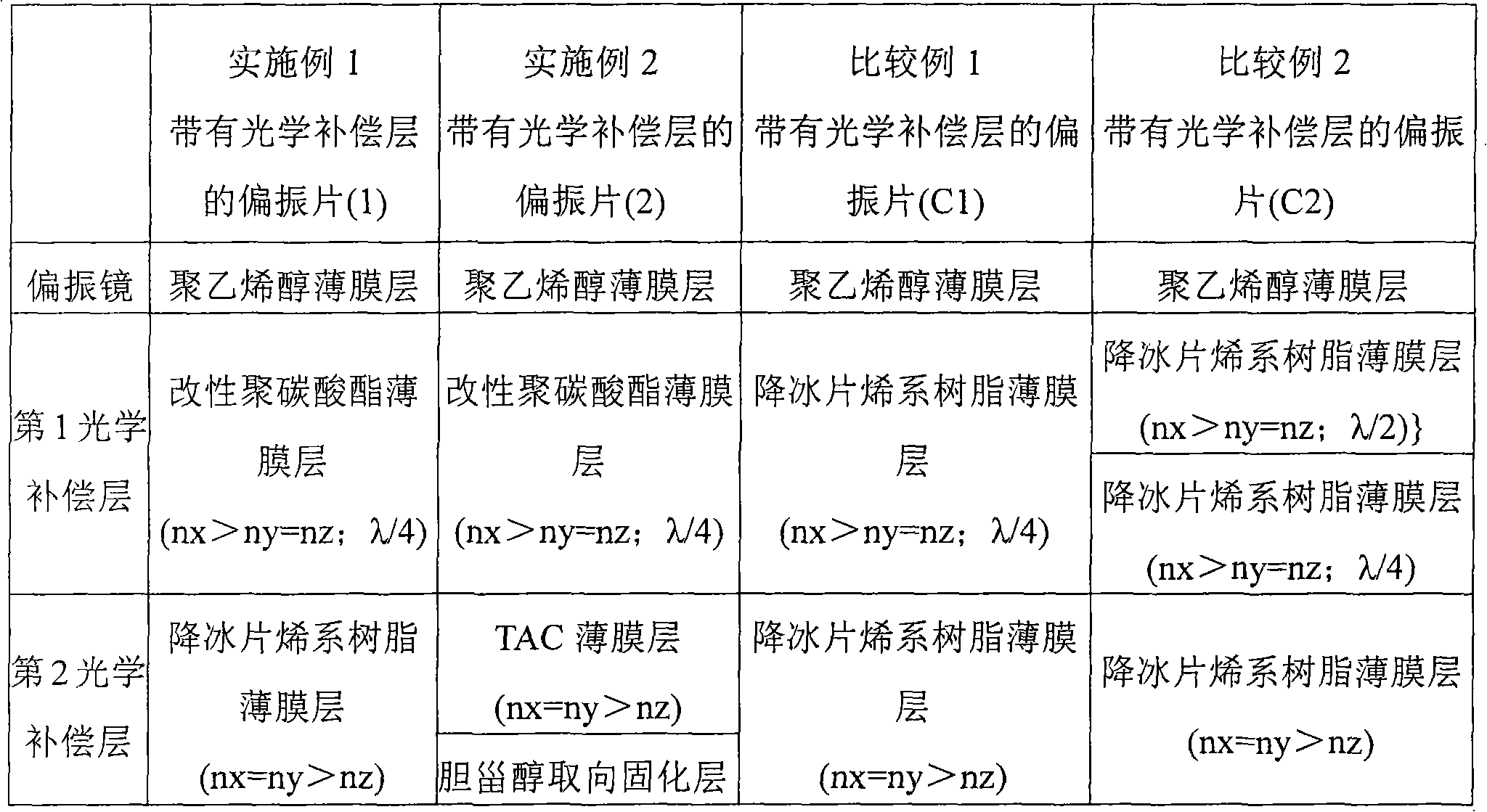

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| photoelasticity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

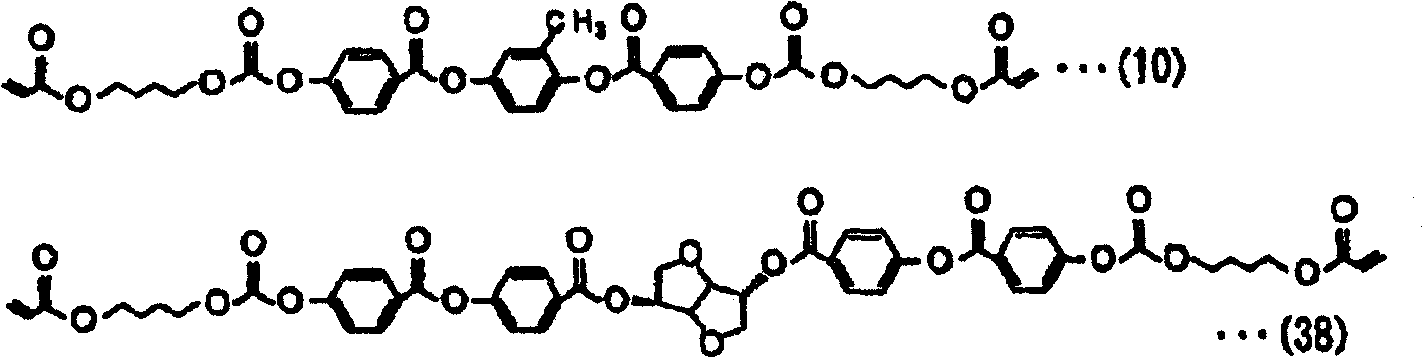

The present invention provides a thin polarizing plate having an optical compensation layer capable of improving visual angle characteristics, realizing a high contrast, preventing interference irregularities and thermal irregularities, suppressing a color shift, exhibiting a preferable color reproducibility, and effectively preventing light leak in the black display. It is also possible to provide a liquid crystal panel and an image display device using such a polarizing plate having an optical compensation layer. The polarizing plate having the optical compensation layer includes a polarizer, a first optical compensation layer, and a second optical compensation layer in this order. The first optical compensation layer has a refractivity distribution of nx > ny = nz and exhibits wavelength distribution characteristics in which the in-plane phase difference Re1 becomes smaller as the wavelength becomes shorter and the in-plane phase difference Re1 is 90 to 160 nm. The second optical compensation layer is a film layer having a refractivity distribution of nx = ny > nz, an in-plane phase difference Re2 0 to 20 nm, and a phase difference in the thickness direction Rth2 30 to 300 nm.

Description

Polarizing plate with optical compensation layer, liquid crystal panel using polarizing plate with optical compensation layer, liquid crystal display device, and image display device technical field The present invention relates to a polarizing plate with an optical compensation layer, a liquid crystal panel using the polarizing plate with an optical compensation layer, a liquid crystal display device, and an image display device. In more detail, the present invention relates to a polarizing plate with an optical compensation layer that contributes to thinning and can prevent hot spots, and can well prevent light leakage during black display, and the use of such a polarizer with an optical compensation layer. Liquid crystal panels, liquid crystal display devices, and image display devices of polarizers. Background technique As a VA-mode liquid crystal display device, in addition to a transmissive liquid crystal display device and a reflective liquid crystal display device,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02B5/30G02F1/1335G02F1/13363

CPCG02F1/133634G02B5/3033G02B5/305G02F1/133528G02B5/30G02F1/13363G02F1/1335

Inventor 首藤俊介冈田裕之千叶刚

Owner NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com