Speaker, speaker diaphragm suspension

A vibrating plate and loudspeaker technology, which is applied in the field of loudspeaker, high-fidelity loudspeaker, loudspeaker vibrating plate and suspension, can solve the problems of lowering the fidelity of reproduced sound and low rigidity, achieve inherent resonance suppression, and solve the problem of surface resonance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

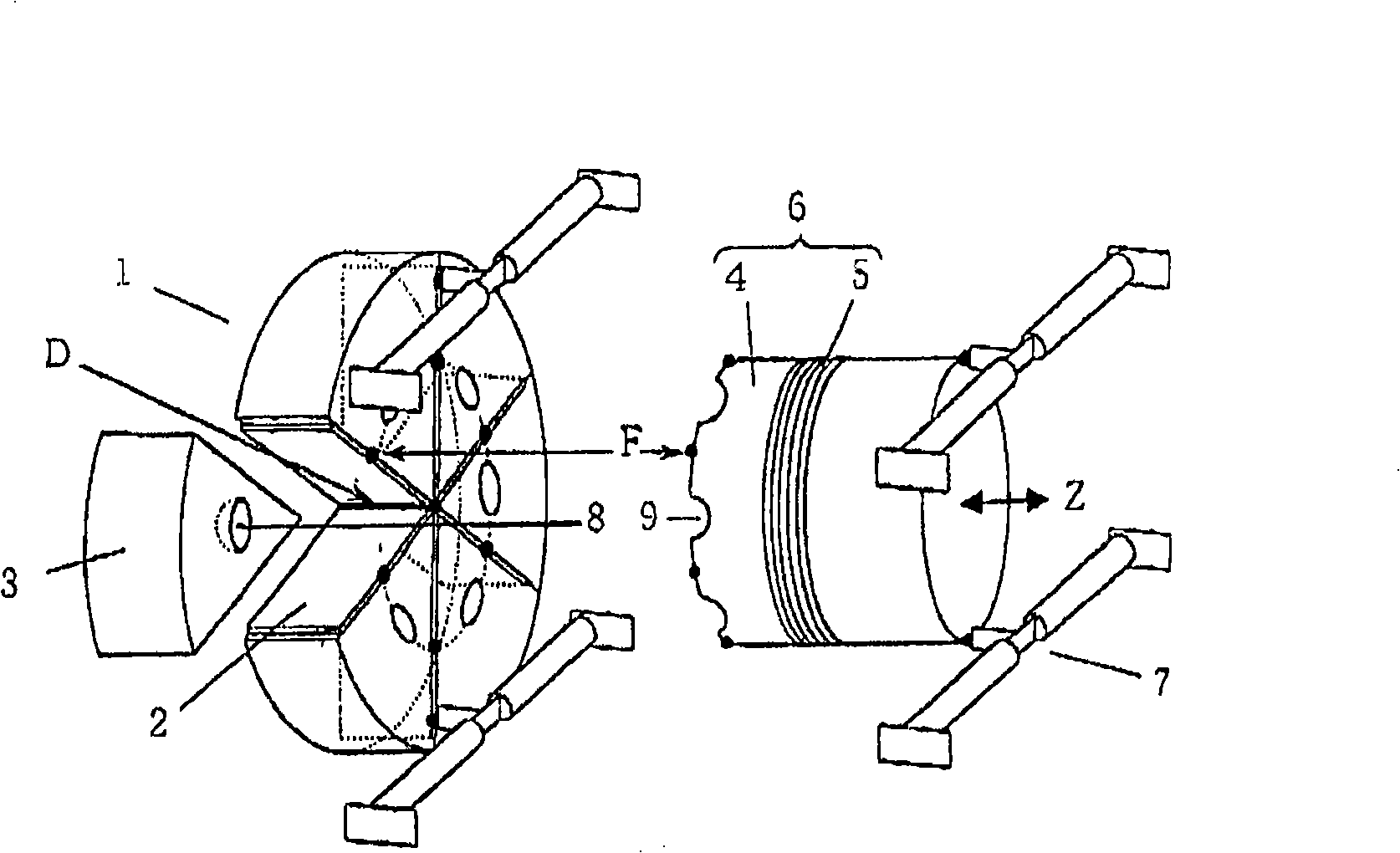

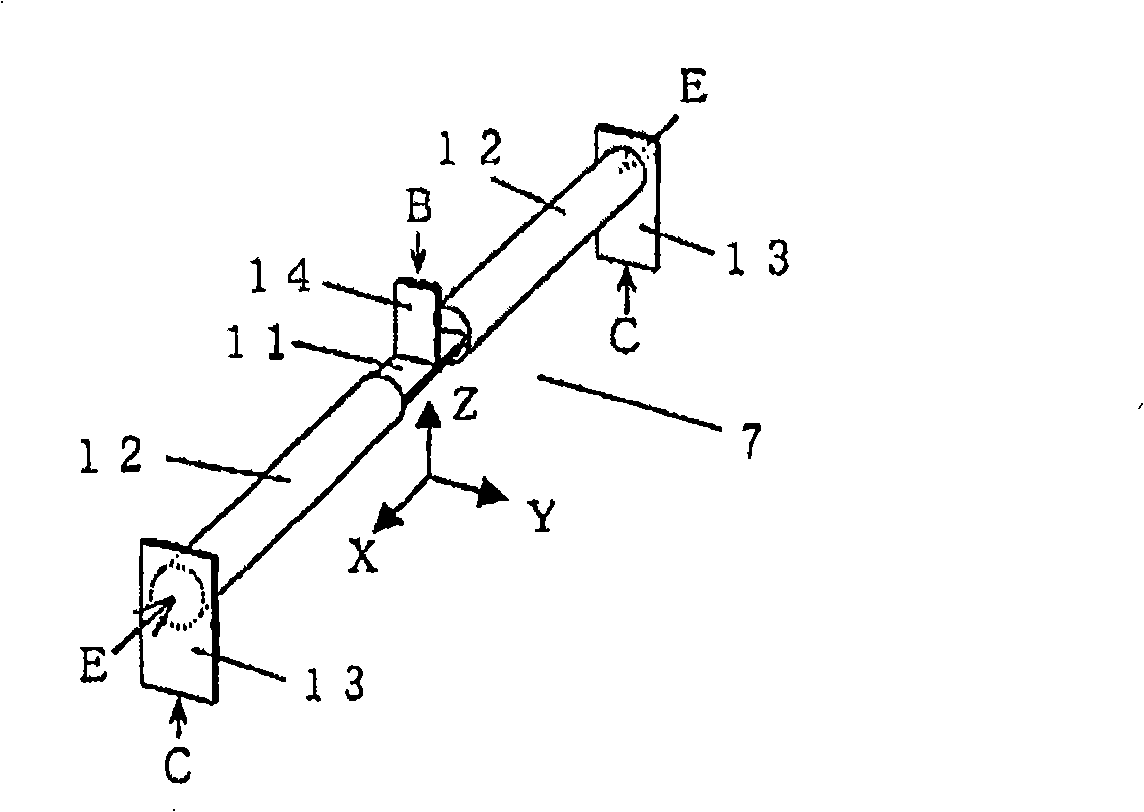

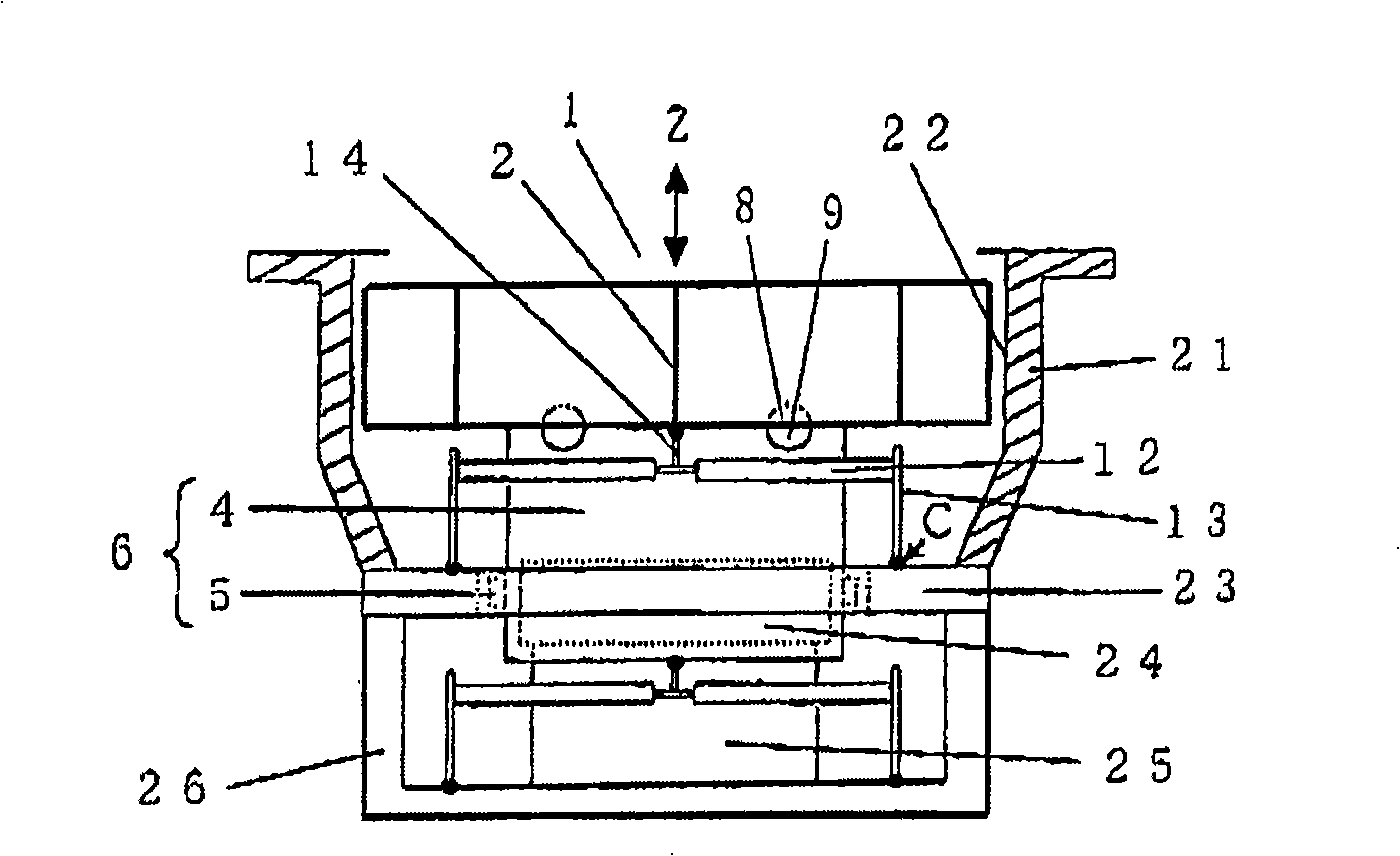

[0046] refer to Figure 1 to Figure 3 Embodiments of the present invention will be described. figure 1 Perspective view of the vibration system for the speaker. It includes a vibrating plate 1 , a driving part 6 and a suspension 7 . Z represents the vibration direction. The left side of the figure is the front, and the right side is the rear. For ease of understanding, one of the filling member 3 and the driving portion 6 is shown in a state separated from the member to which it is fastened.

[0047] figure 1 Among them, 1 represents a disc-shaped vibrating plate. The diameter is chosen to be eg 120 mm and the thickness eg 20 mm. Since this vibrating plate 1 has a small specific gravity, even if it is made to this thickness, the mass will not become too large.

[0048] 2 is a frame part. It consists of a number of flat plate parts of the same shape. In this embodiment there are six plate parts. All plate members are arranged at substantially equal angular intervals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com