Process for producing high purity meta-xylene, comprising simulated moving bed adsorption and crystallization

A technology for simulating moving bed and m-xylene, applied in the field of copolymers with terephthalic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

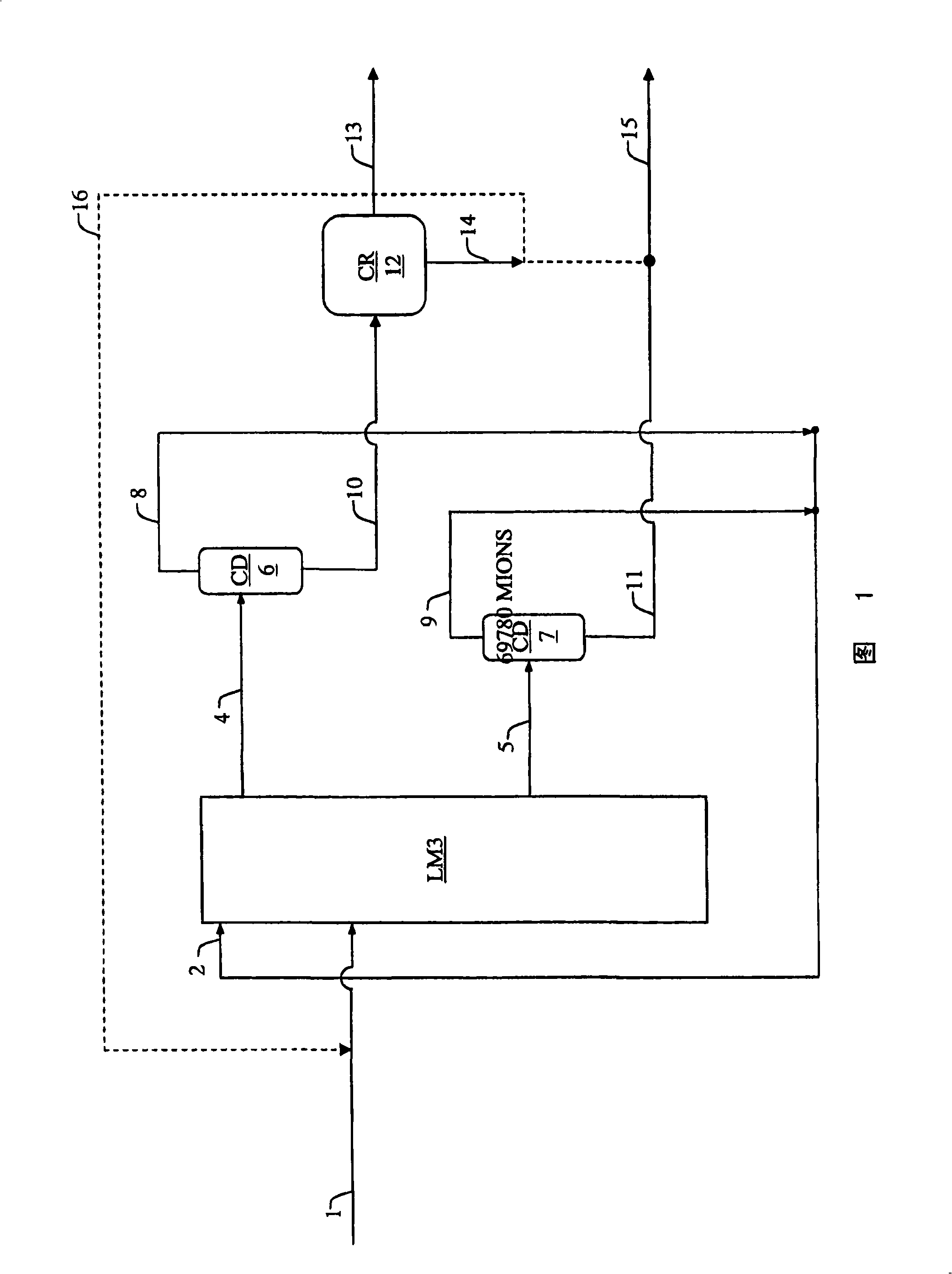

Image

Examples

Embodiment 1

[0077] Embodiment 1 (according to prior art)

[0078] The prior art process includes simulated moving bed separation equipment capable of producing meta-xylene with a purity of 99.1%.

[0079] This example illustrates the production of meta-xylene with a purity of 99.1%. m-xylene was separated by countercurrent simulated moving bed adsorption. The ortho-xylene-rich starting material has the following weight composition:

[0080] PX: 3.57% p-xylene

[0081] MX: 55.84% m-xylene

[0082] OX: 28.36% o-xylene

[0083] EB: 11.79% ethylbenzene

[0084] TOL: 0.44% toluene.

[0085] The pilot plant used consisted of 24 towers 1.1 m long and 0.021 m in diameter. Each tower is equipped with 240.6g of sodium-exchanged Y zeolite, and the moisture content represented by the loss on ignition at 900° C. is lower than 0.1%.

[0086] The operating temperature is 160°C and the suction pressure of the circulation pump is maintained at 10 bar.

[0087] All of these streams are continuou...

Embodiment 2

[0101] Embodiment 2 (the present invention)

[0102] This example illustrates the plant of the invention comprising 15 adsorbent bed adsorption plants coupled to the crystallization section and capable of producing m-xylene with a purity of 99.7%.

[0103] The pilot plant used consists of 15 towers with a length of 1.1 m and a diameter of 0.021 m. Each tower is equipped with 240.6 g of sodium-exchanged Y zeolite, and the moisture content expressed by the loss on ignition at 900° C. is less than 0.1%. The operating temperature is 160°C and the suction pressure of the circulation pump is maintained at 10 bar.

[0104] All of these streams are continuously injected or withdrawn under flow control, with the exception of raffinate, which is continuously withdrawn under pressure control, said injection and withdrawal rates being expressed under the conditions of the process.

[0105] The total number of beds is 15, which are allocated in the following manner.

[0106] - 3 beds b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com