Planet speed regulator

A speed governor, planetary technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem that cannot be applied to the field of large industrial test bench, the speed control device is not widely used, and the support at both ends is inconvenient, etc. problems, to achieve the effect of ensuring durability and flexibility, small size and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

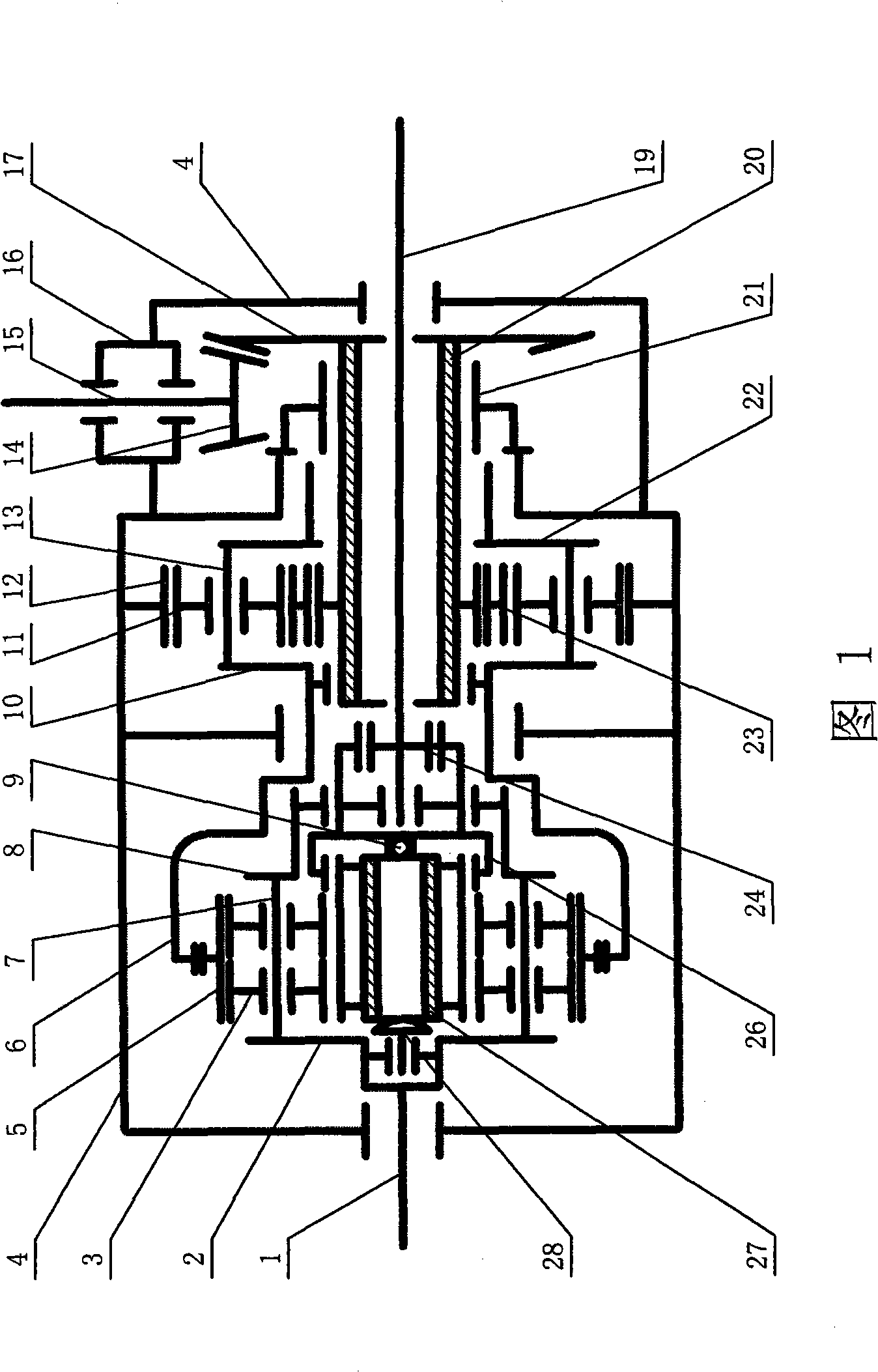

[0040] Embodiment 1: As shown in FIG. 1, the planetary governor includes a base 4 in which a main power flow transmission mechanism and a secondary power flow transmission mechanism are connected by a coupling disk 6.

[0041] In this embodiment, the main power flow transmission mechanism adopts a single-pair double-row planetary gear transmission mechanism, and the secondary power flow transmission mechanism adopts a single-row planetary gear reduction mechanism to form a two-disk combined planetary gear transmission mechanism, and the transmission pair adopts bevel gear pairs. .

[0042] A low-speed output speed regulating device is formed by a single-pair double-row planetary gear transmission mechanism, a bevel gear pair-single-row planetary gear reduction mechanism.

[0043] The single-pair double-row planetary gear transmission mechanism includes: an internal gear 26 connected with the main power shaft 19, a first internal gear 5 connected with the coupling plate 6, a first ...

Embodiment 2

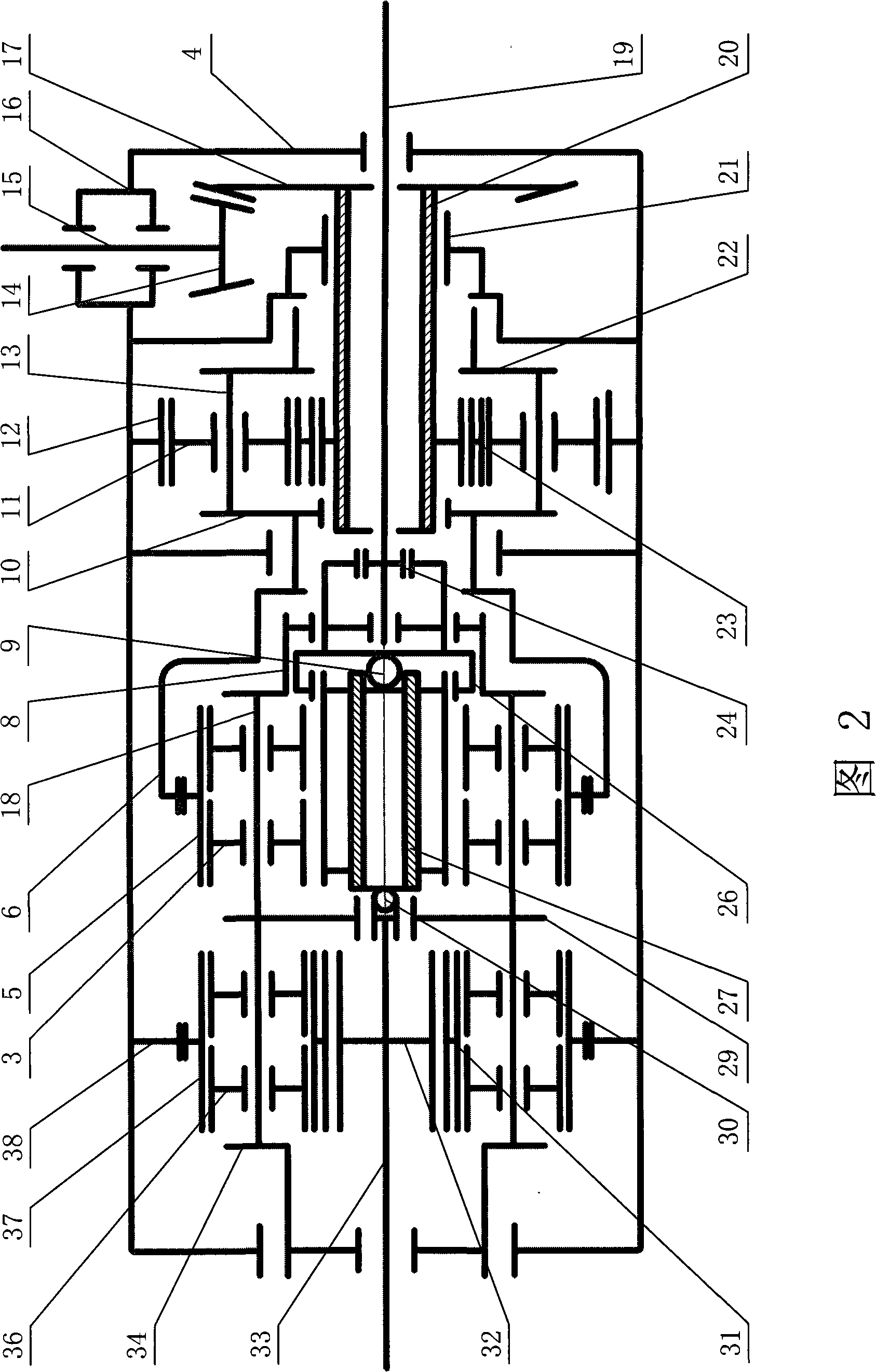

[0054] Embodiment 2: As shown in Figure 2, compared with Embodiment 1, this embodiment has the same secondary power flow transmission mechanism, and a planetary gear transmission mechanism is added to the main power flow transmission mechanism, that is, the main power flow transmission mechanism includes Two pairs of double-row planetary gear transmission mechanisms with different structures. In this way, this embodiment is mainly composed of two pairs of double-row planetary gear transmission mechanisms, a bevel gear pair-single-row planetary gear reduction mechanism together to form a three-disc combination with high speed output (the output speed can be lower or higher than the main motor speed) Speed regulating device.

[0055] In the main power flow transmission mechanism, the two pairs of double-row planetary gear transmission mechanisms include a pair of double-row planetary gear transmission mechanisms that have been described in Embodiment 1, that is, the first internal...

Embodiment 3

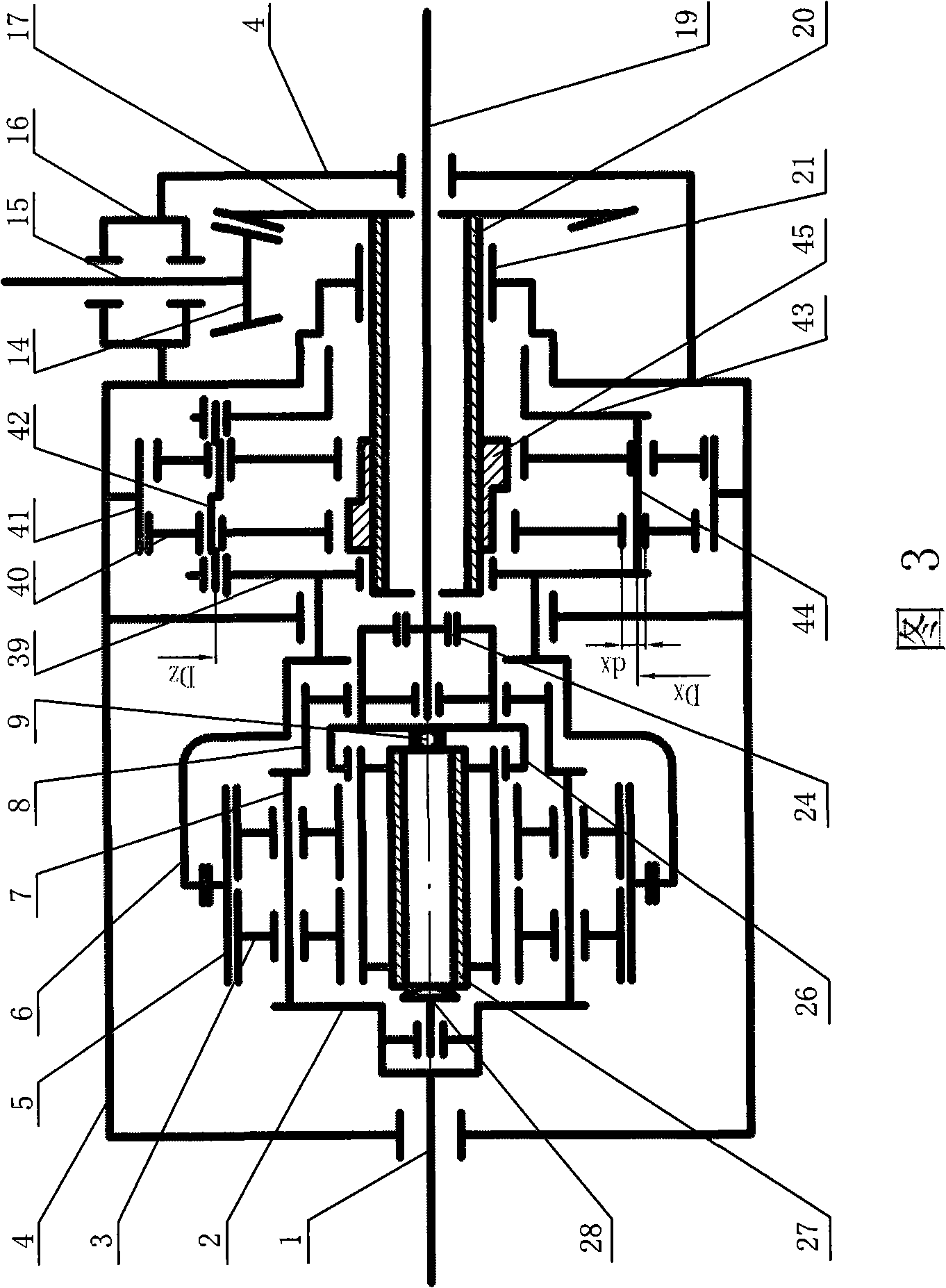

[0060] Embodiment 3: As shown in FIG. 3, in this embodiment, the structure of the main power flow transmission mechanism is the same as that of Embodiment 1, and the secondary power flow transmission mechanism adopts a bevel gear pair-star gear transmission mechanism. That is, it is mainly a two-disk combined speed regulating device composed of a single pair of double-row planetary gear transmission mechanism and a bevel gear pair-star gear transmission mechanism.

[0061] The single-pair double-row planetary gear transmission mechanism has been described in the first embodiment.

[0062] In the bevel gear pair-star gear transmission mechanism, the bevel gear pair includes a small bevel gear 14 and a large bevel gear 17 connected with the control shaft 15.

[0063] The planetary gear transmission mechanism includes: a hollow sleeve 20 with a double crank eccentric sleeve 45 fitted on the large bevel gear 17, a third internal gear 41 fixed on the base 4, two technical parameters ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com