Heat reclamation method for wastewater of dyeing and printing industry

A technology for heat recovery and waste water, applied in separation methods, chemical instruments and methods, filtration circuits, etc., can solve problems such as difficult removal, easy fouling, troubles, etc., and achieve the effect of fast cost recovery and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

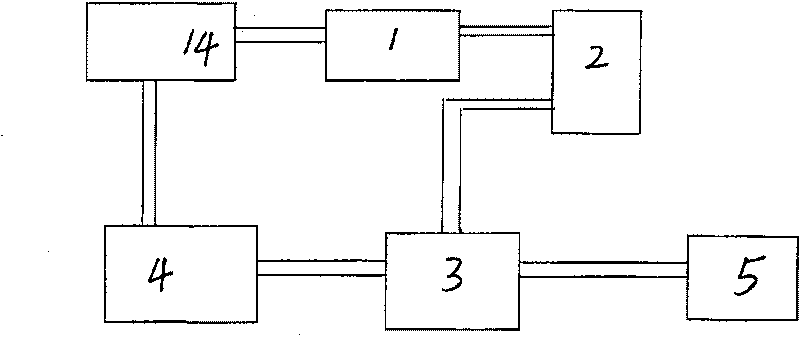

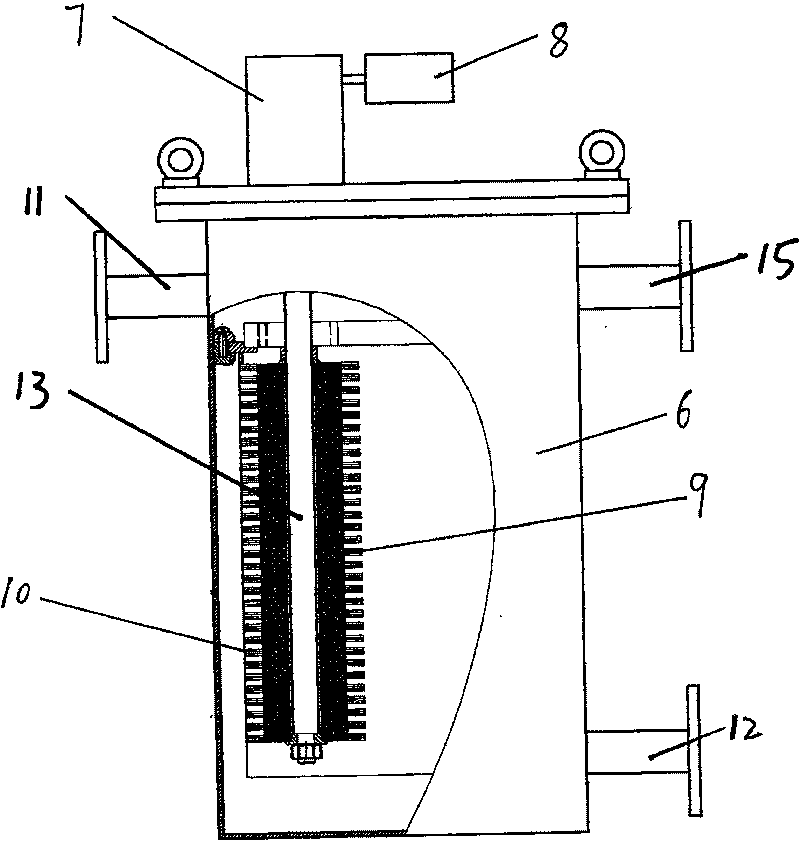

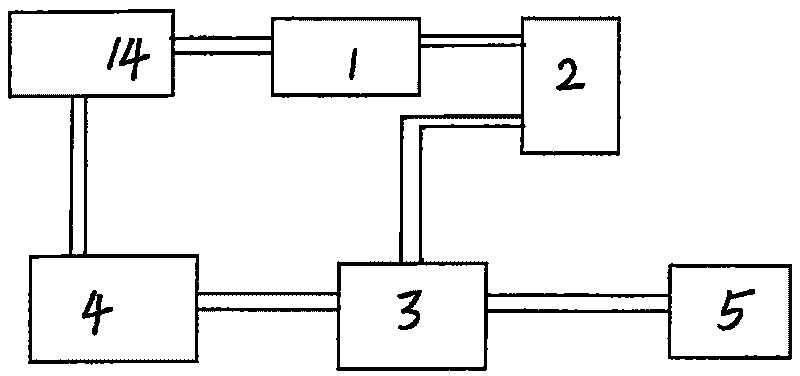

[0011] The process was tested in a printing and dyeing factory, in figure 1 , figure 2 The waste heat sewage from the printing and dyeing factory in China Printing and Dyeing Factory passes through the primary filter 1, and the waste hot water passes through the secondary filter device 2, flat plate heat exchanger 3, and the exchanged cold water becomes hot water to the heat preservation hot water tank 4 for standby, in the heat preservation water tank The hot water becomes waste hot water after use, and the water in the heat preservation water tank is transported to the printing and dyeing factory for printing and dyeing 14, and the waste water exchanged by the plate heat exchanger 3 is treated in the sewage processor 5 and then discharged; the secondary filter device 2 includes a closed hollow cylinder 6, a reducer 7, a motor 8, a filter cleaning brush 9, and a filter 10. The cylinder 6 has a water inlet 11 and a water outlet 12; the motor 8 and the reducer 7 The reducer 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com