High-salt complex wastewater reuse and zero discharge integrated equipment and technology

A zero-discharge, complex technology, applied in general water supply conservation, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as waste of water resources, low water recycling rate, and large discharge volume. Reliable operation, inhibition of silicon scaling and organic contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

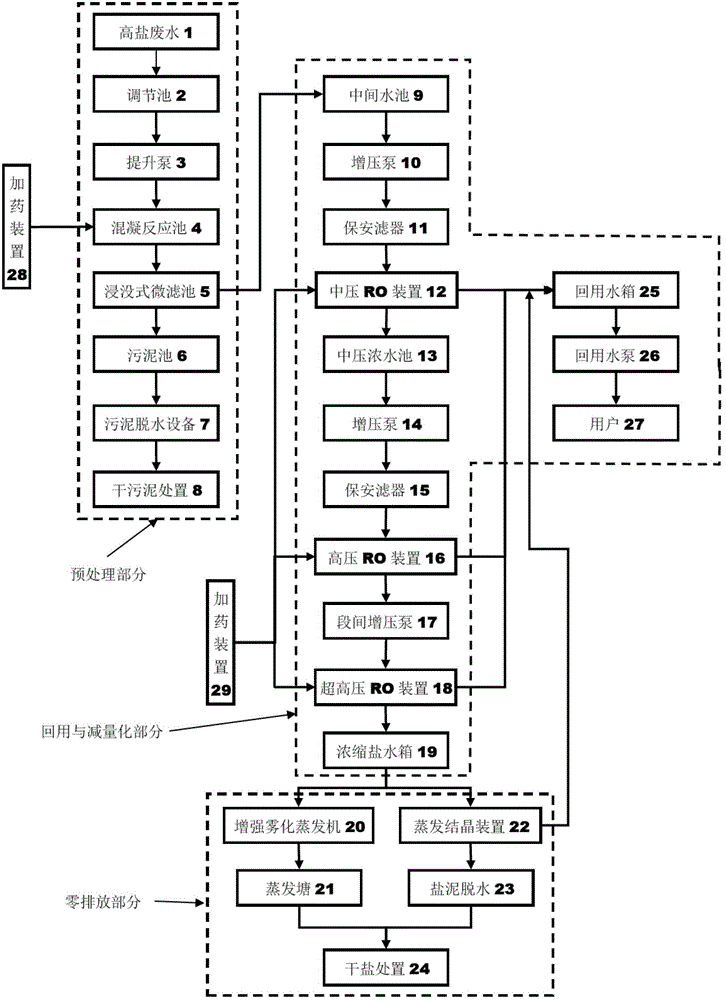

[0035] like figure 1 As shown, this integrated equipment is used to treat complex wastewater with high salt content in coal chemical industry. The wastewater comes from reverse osmosis concentrated water for sewage reuse and reverse osmosis concentrated water from desalination station.

[0036] First, the high-salt complex wastewater is homogenized and equalized through the regulating tank, and the raw water is sent to the coagulation reaction tank through the lift pump, where lime or sodium hydroxide, sodium carbonate, PAC, and PAM are sequentially added from the dosing device. Sodium hydroxide is formulated into a 20% concentration solution according to the raw water concentration of 1.5g / L, and sodium carbonate is formulated into a 15% solution according to the raw water concentration of 3.2g / L. The solution is added at a concentration of 30mg / L, and the solution made of PAM with a concentration of 0.3% is added at a concentration of 3mg / L. Membrane fouling affects the ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com