Integral immobilization pH gradient production method and application thereof

An integral, gradient technology, applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., to achieve stable gradient, low cost, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

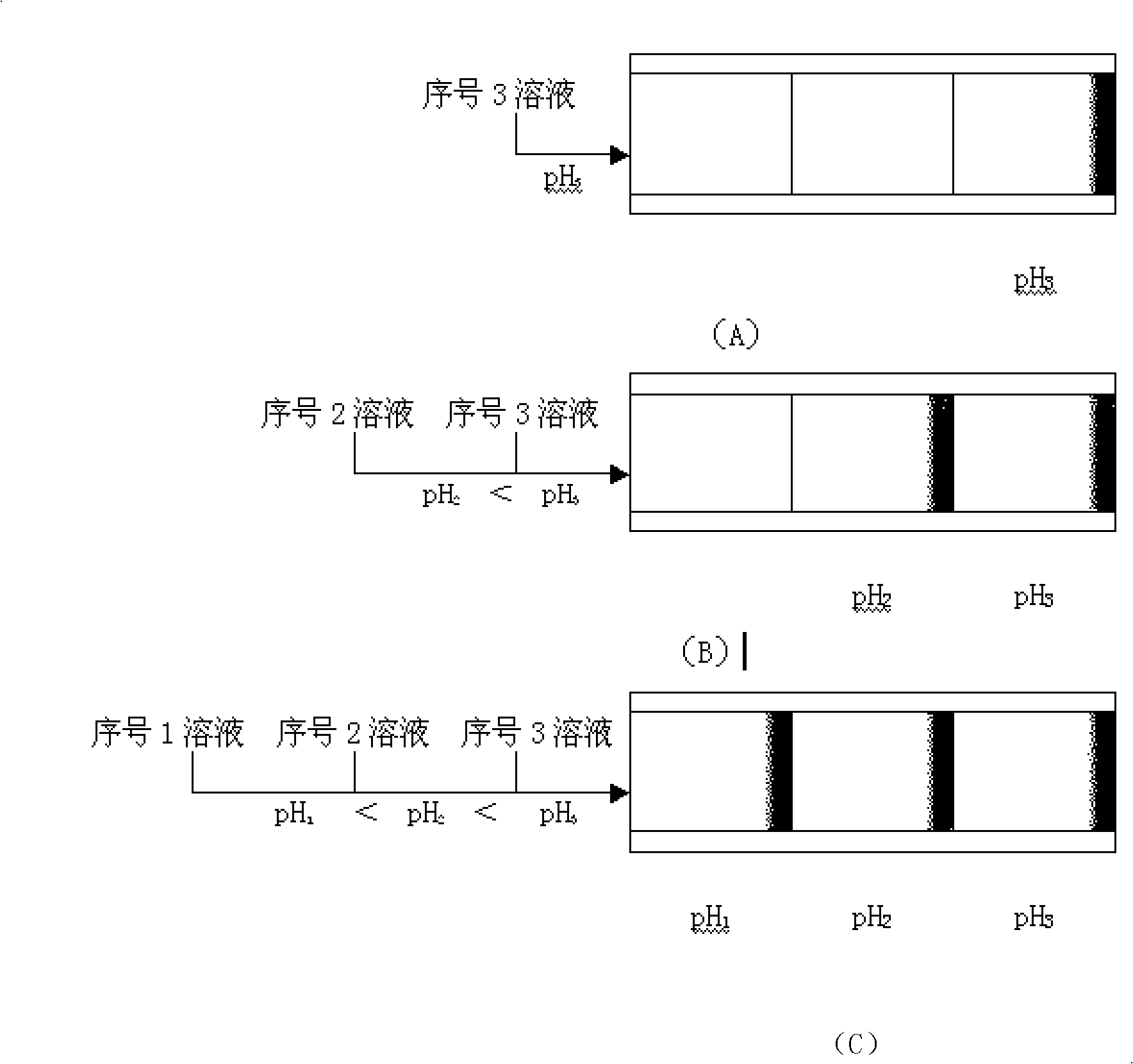

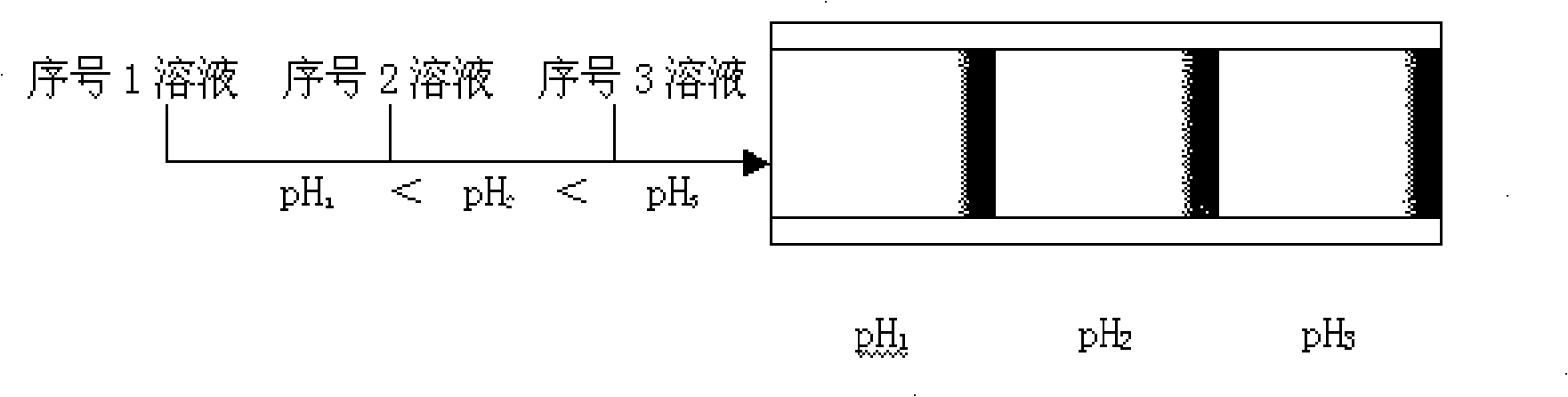

Method used

Image

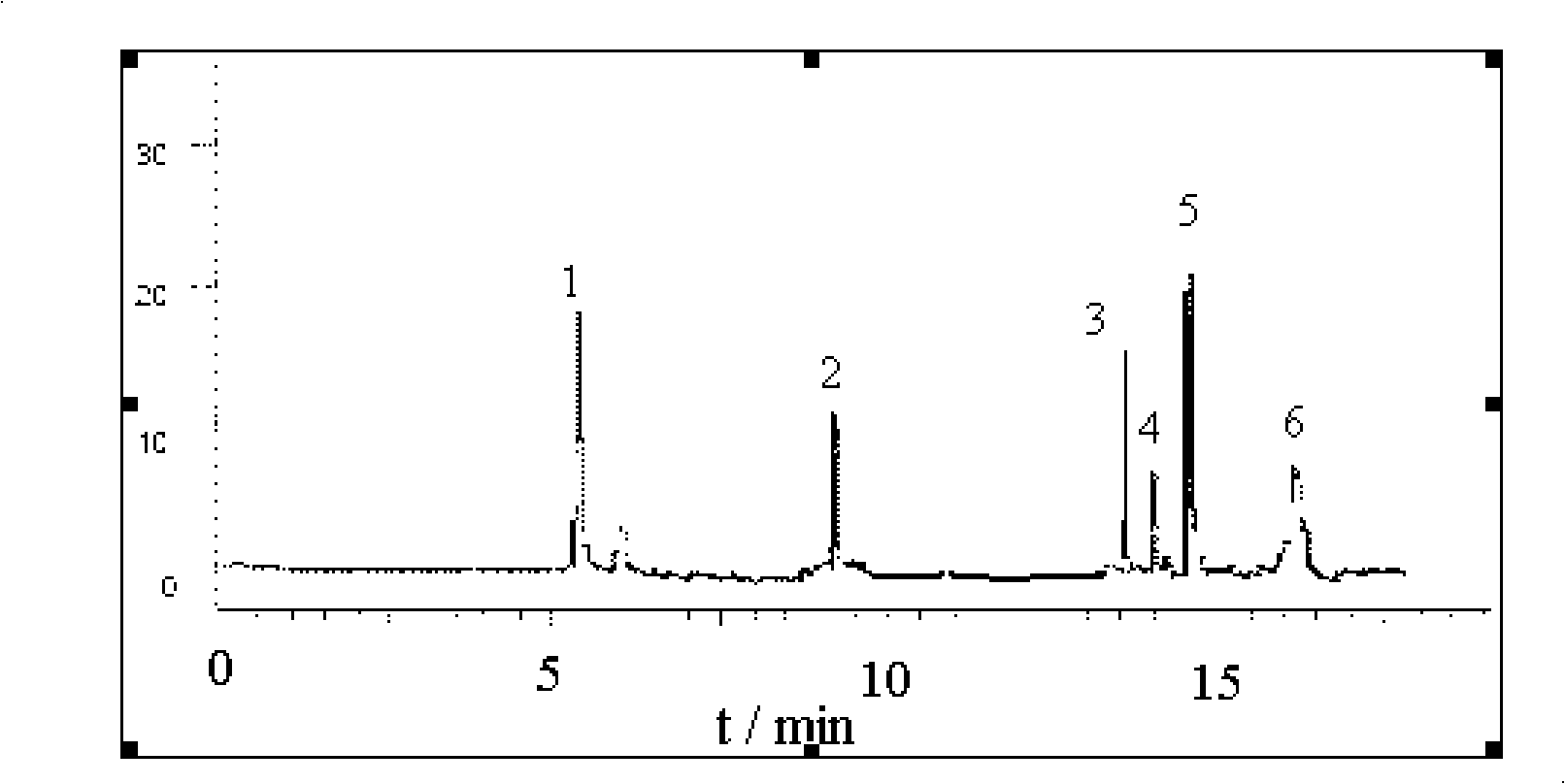

Examples

Embodiment 1

[0040] Example 1: Weigh (quantify) the medicines listed in Table 1 with serial numbers 1-22, put them in 22 1L volumetric flasks, stir them in an ice-water bath to make a solution, and store it in a refrigerator at -20°C. When using a pipette, take out the required amount for use. This series of solutions can establish a pH gradient between pH 2-11. The polymerization reaction is carried out in a 60°C water bath, and the polymerization time is 5 to 48 hours.

Embodiment 2

[0041] Example 2: Compared with Example 1: In this example, the concentrations of acid and basic monomers used are different while keeping the concentrations of neutral monomers and initiators unchanged. By increasing the amount of AMPS in the serial numbers 1, 2, and 3 in Table 1 to reach 20, 18, and 16 grams, respectively, the pH range was extended to pH=1 in the low pH direction; by increasing the serial numbers 20 and 21 in Table 1 The amount of DEAEMA in, 22 is 230, 270, and 300 grams, respectively, so that the pH range is extended to pH=14 in the high pH direction. At the same time, the polymerization temperature and time remain unchanged.

Embodiment 3

[0042] Example 3: Compared with Examples 1 and 2: This example uses different acidic monomers (such as vinyl sulfonic acid or sodium vinyl sulfonate) and basic monomers (such as vinyl amine). At the same time, the polymerization reaction The temperature and time remain unchanged, so as to achieve a gradient between pH=1-14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com