Automotive fuels and fine chemicals from crude tall oil

A technology of tall oil and esterification, applied in the field of manufacturing fatty acid alkyl esters, can solve the problem of high content of sulfur compounds, and achieve the effects of increasing yield and improving oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

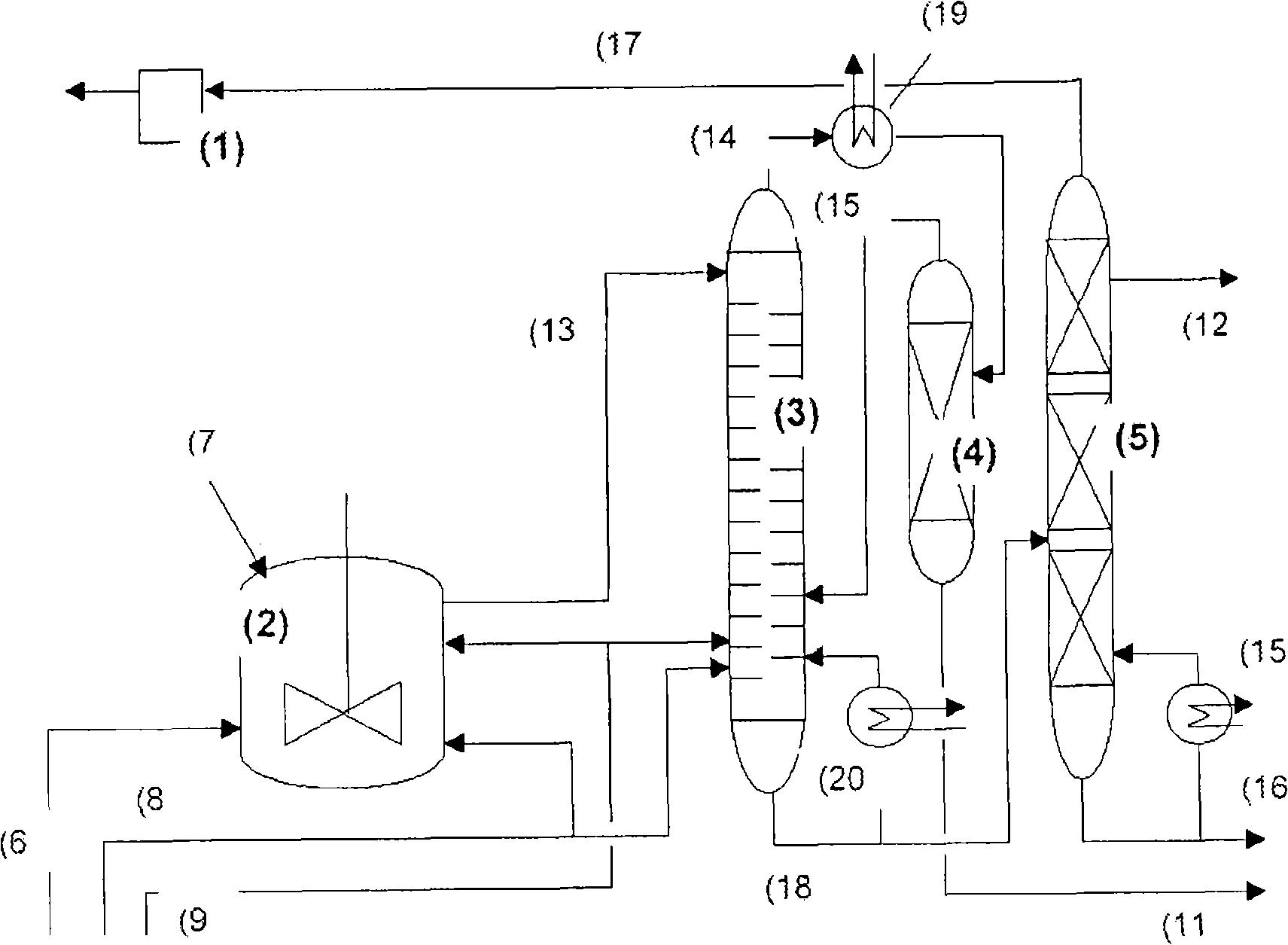

[0028]The inventors of the present invention have discovered a new and efficient process for the preparation of pure fatty acid alkyl esters (fatty acid alkyl esters) in high yields from fatty acids present in tall oil. In addition, a valuable by-product stream containing resin acids was also found. Optionally, a stream of neutral components can be recovered as another valuable by-product stream.

[0029] The feed material of the present invention is tall oil derived from crude tall oil soaps traditionally recovered in alkaline pulp mills. Crude tall oil soap contains fatty and resinic acid soaps, neutral organic components and a small portion of entrained black liquor components (lignin, sulfur compounds and fibers). As a first step, most of the entrained black liquor components in the crude tall oil soap can be removed by mechanical / physical separation using, for example, a decanter centrifuge. The mechanically / physically purified crude tall oil soap may then be further pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com