Four-air valve motorcycle engine valve clearance adjustment structure

A technology for engine valve and clearance adjustment, which is applied to engine components, machines/engines, mechanical equipment, etc., and can solve problems such as poor repeatability, low adjustment accuracy, and large elastic deformation of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

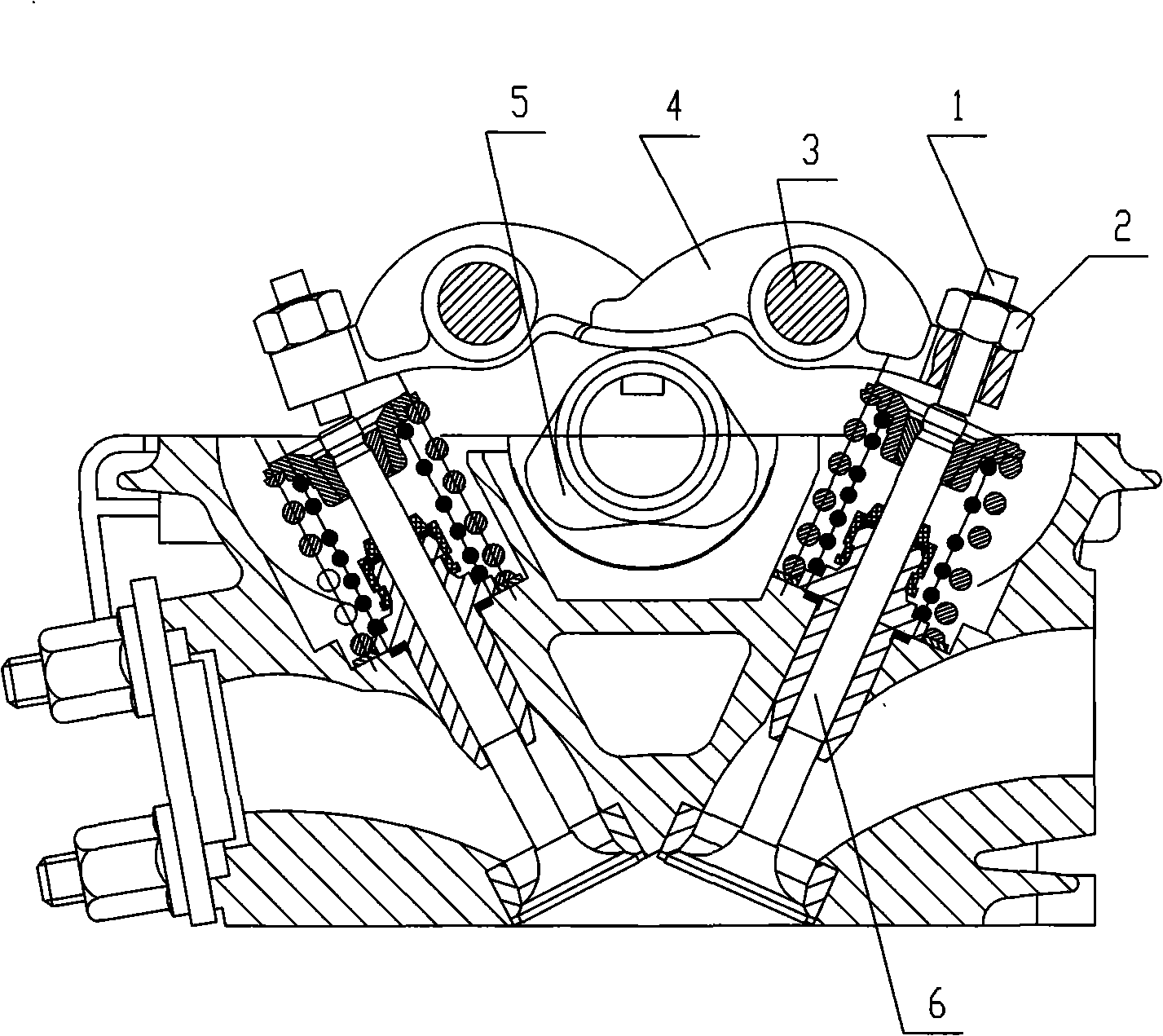

[0015] Embodiment 1: a kind of four-valve motorcycle engine valve clearance adjustment structure such as figure 2 shown, including:

[0016] - the cam 7 in the middle of the engine cylinder,

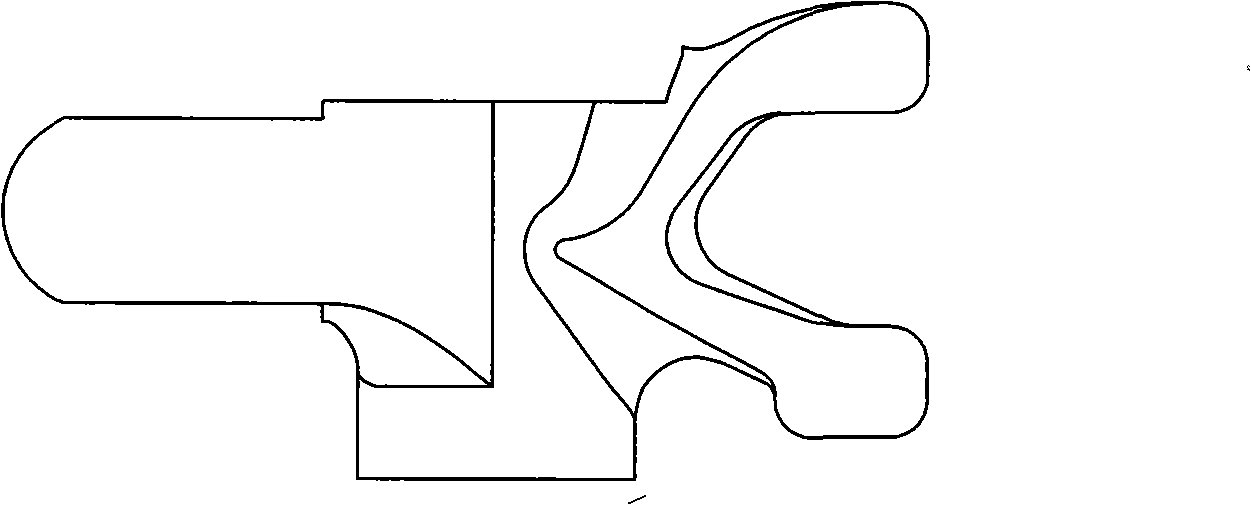

[0017] ——The intake rocker arm 8 is positioned on and moves around the intake rocker shaft 9, the active end of the intake rocker arm 8 is connected to the engine cam 7, and the output end of the intake rocker arm 8 is as follows image 3 As shown, it is a Y-shaped bifurcation, and the ends of the two bifurcations respectively drive an intake valve stem 14, and the upper top of the intake valve stem 14 is fixed with a threaded connection. Valve clearance adjusting gasket 10. The output end of the intake rocker arm 8 is arc-shaped and directly contacts the upper plane of the intake valve clearance adjustment gasket 10, and the surface roughness of the contact surface between them is Ra0.050.

[0018] ——The exhaust rocker arm 11 is positioned on and moves around the exhaust rocker shaf...

Embodiment 2

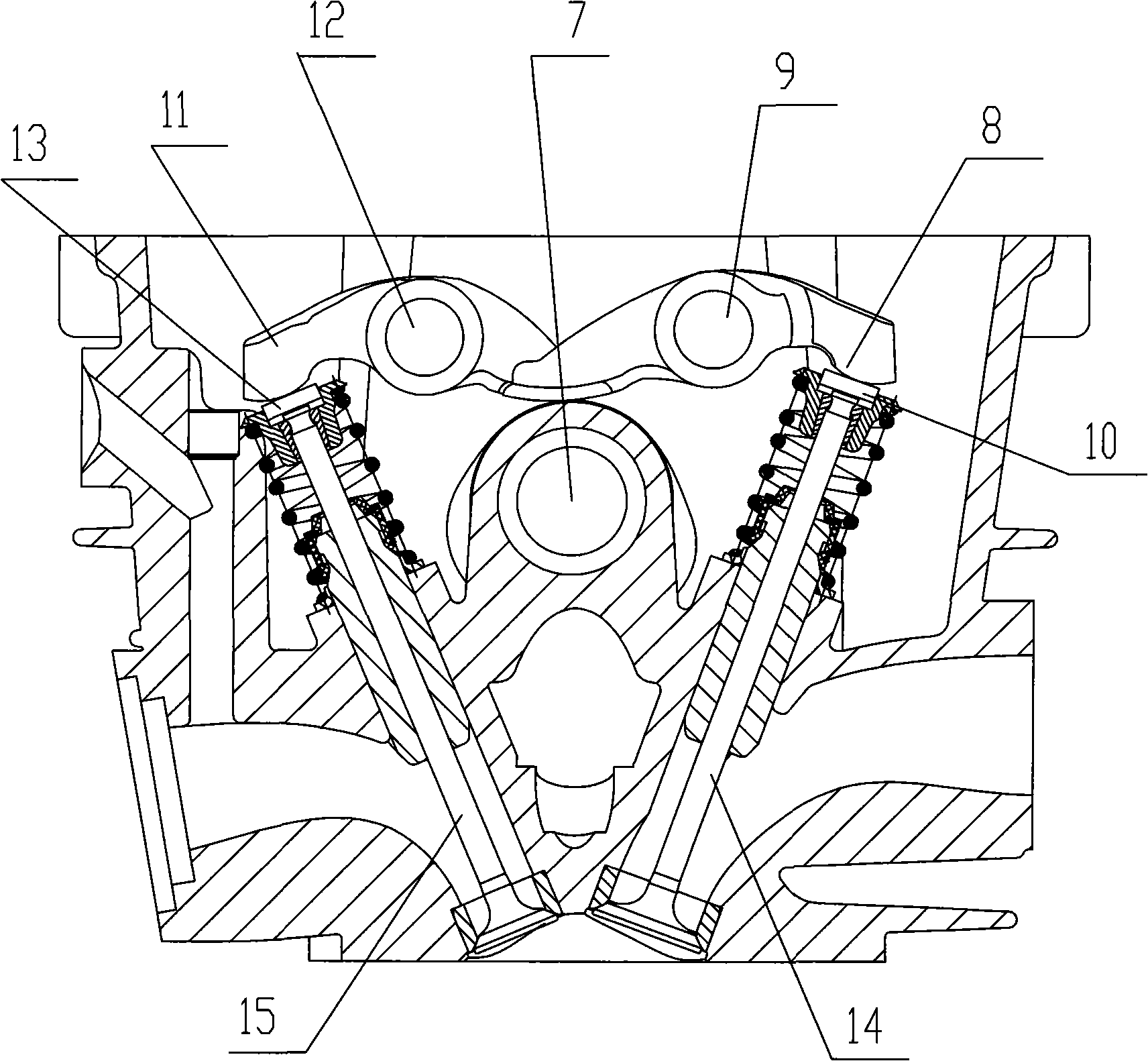

[0019] Embodiment 2: a kind of four-valve motorcycle engine valve clearance adjustment structure such as Figure 4 As shown, it is mainly on the basis of the above-mentioned embodiment 1, mainly changing the contact mode between the intake and exhaust valve rocker arms and the intake and exhaust valve clearance adjustment gaskets. details as follows:

[0020] Take the intake valve transmission structure as an example (the exhaust valve transmission structure is similar), such as Figure 5 As shown, the upper top of the intake valve rod 14 is fixed with mortise and rivet interference fit-an intake valve clearance adjustment gasket 10 with a corresponding specific height with a hemispherical top surface according to different intake valve clearance requirements. The output end of the intake rocker arm 8 cooperates with the spherical shape of the intake valve clearance adjustment gasket 10 to be provided with a semi-concave spherical pit, so that the output end of the intake roc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com