Load angle direct measurement method of hydroelectric synchronous machine

A technology of synchronous generator and measurement method, which is applied in the direction of motor generator testing, etc., to achieve the effect of convenient real-time calculation, avoiding modification, and convenient and fast solution

Active Publication Date: 2010-09-08

NARI TECH CO LTD +1

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But in fact, due to the fact that a large number of gear plates of generator sets that have been put into operation have already been opened, and the importance of power generation equipment, it is very difficult to re-modify the gear plate of generators in practical engineering applications.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

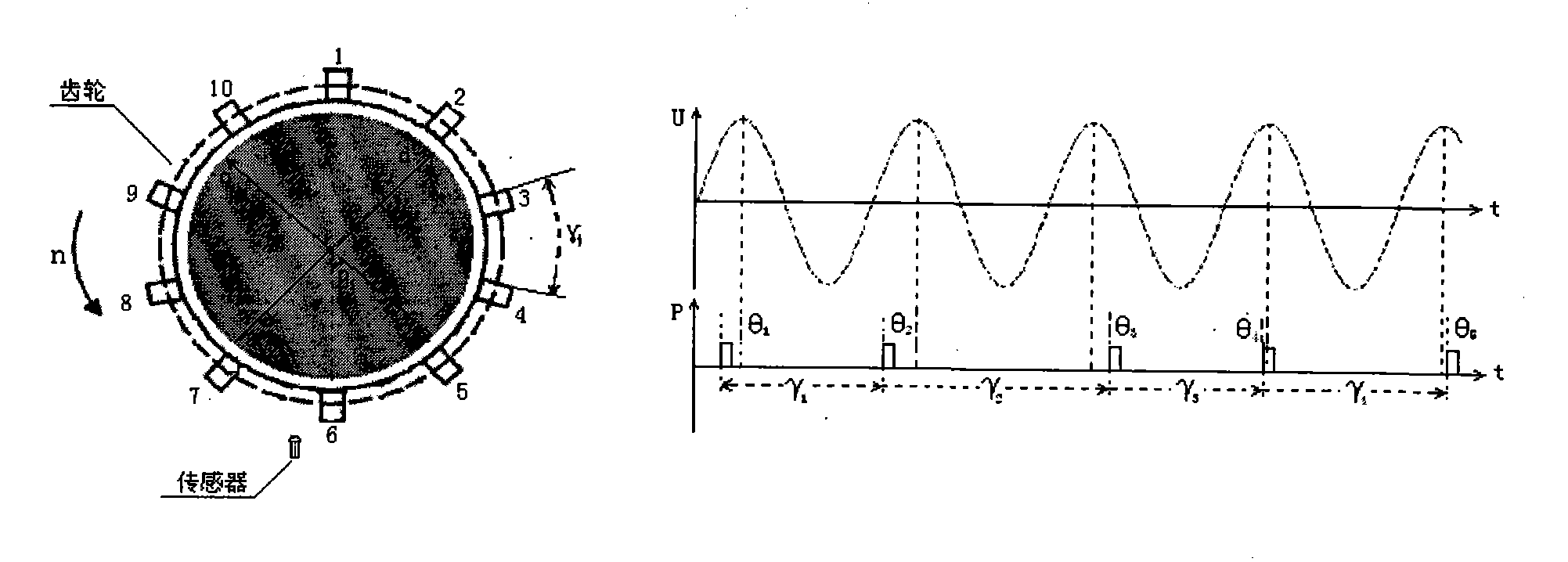

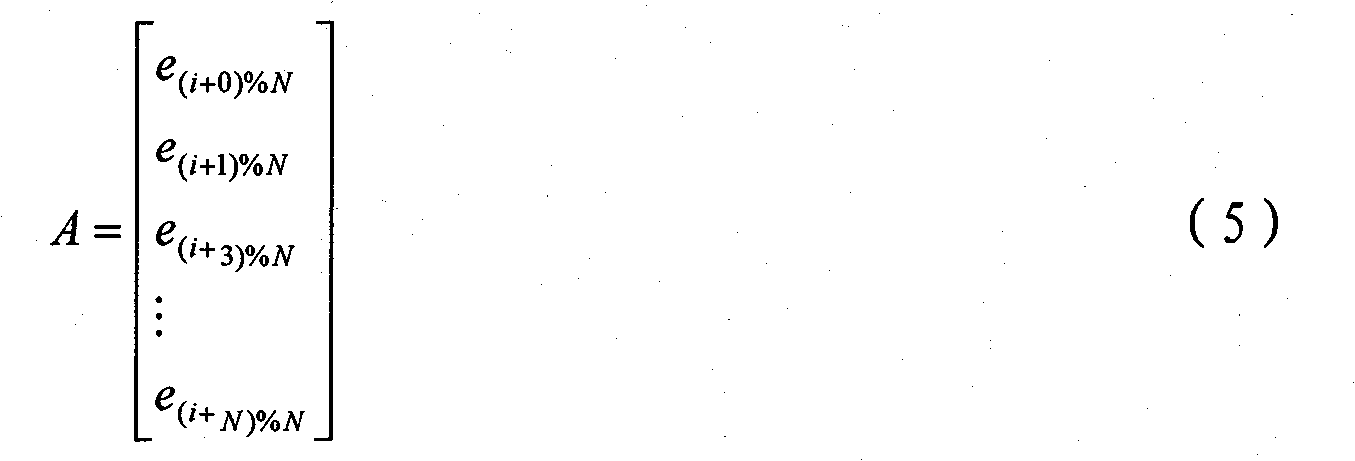

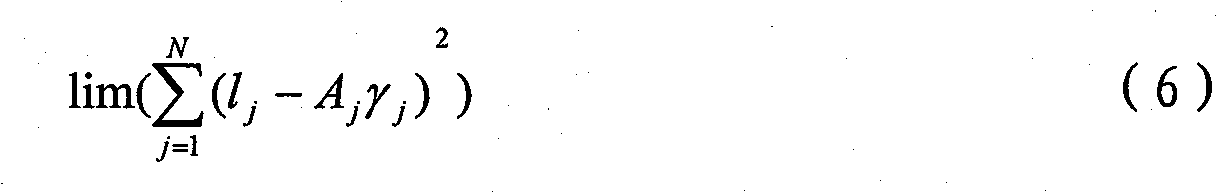

The present invention discloses a method for directly measuring the power angle of a hydroelectric synchronous machine, wherein the method comprises the following steps: at the state that the generator is unloaded, obtaining a preliminary phase angle and a tooth pitch characteristic parameter of the fluted disc of the generator rotor by a PMU device through a sensor; when the generator is operated with load, matching the corresponding relationship between the preliminary phase angle sequence and the tooth pitch sequence through measuring the fluted disc characteristic and tooth pitch characteristic at this time; and calculating the real-time power angle through the matching relationship. The method according to the invention can measure the initiative error angle of the position signal ofthe generator and directly obtain an accurate power angle of generator at the state that the existing generator gear is not improved.

Description

technical field The invention relates to a method for directly measuring the power angle of a water wheel synchronous generator. Background technique The trend of the interconnection of major power grids in my country makes the monitoring of power grid security and stability particularly important. Since the generator power angle is an important state quantity that characterizes the safety and stability of the power grid, the Wide Area Measurement System (WAMS) and Synchronized Phasor Measurement Unit (PMU) constructed using synchronous clock technology have been widely promoted and applied in recent years. The more accurate method of measuring the power angle of the generator is: directly measure the position angle of the generator rotor in a certain space, so as to calculate the internal potential phase angle, and obtain it by the angle difference between the internal potential phase angle and the generator terminal voltage generator power angle. The method of directly ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01R31/34

Inventor 丁孝华孙国城周捷杨永标赵景涛

Owner NARI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com