Electronic photographic photoreceptor, processing cassette and image forming device

A technology for electrophotography and photoreceptors, which is applied in the field of electrophotographic photoreceptors and image forming devices. It can solve problems such as image quality degradation, achieve the effects of suppressing interference fringes, improving the suppression effect, and suppressing the rise of residual potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

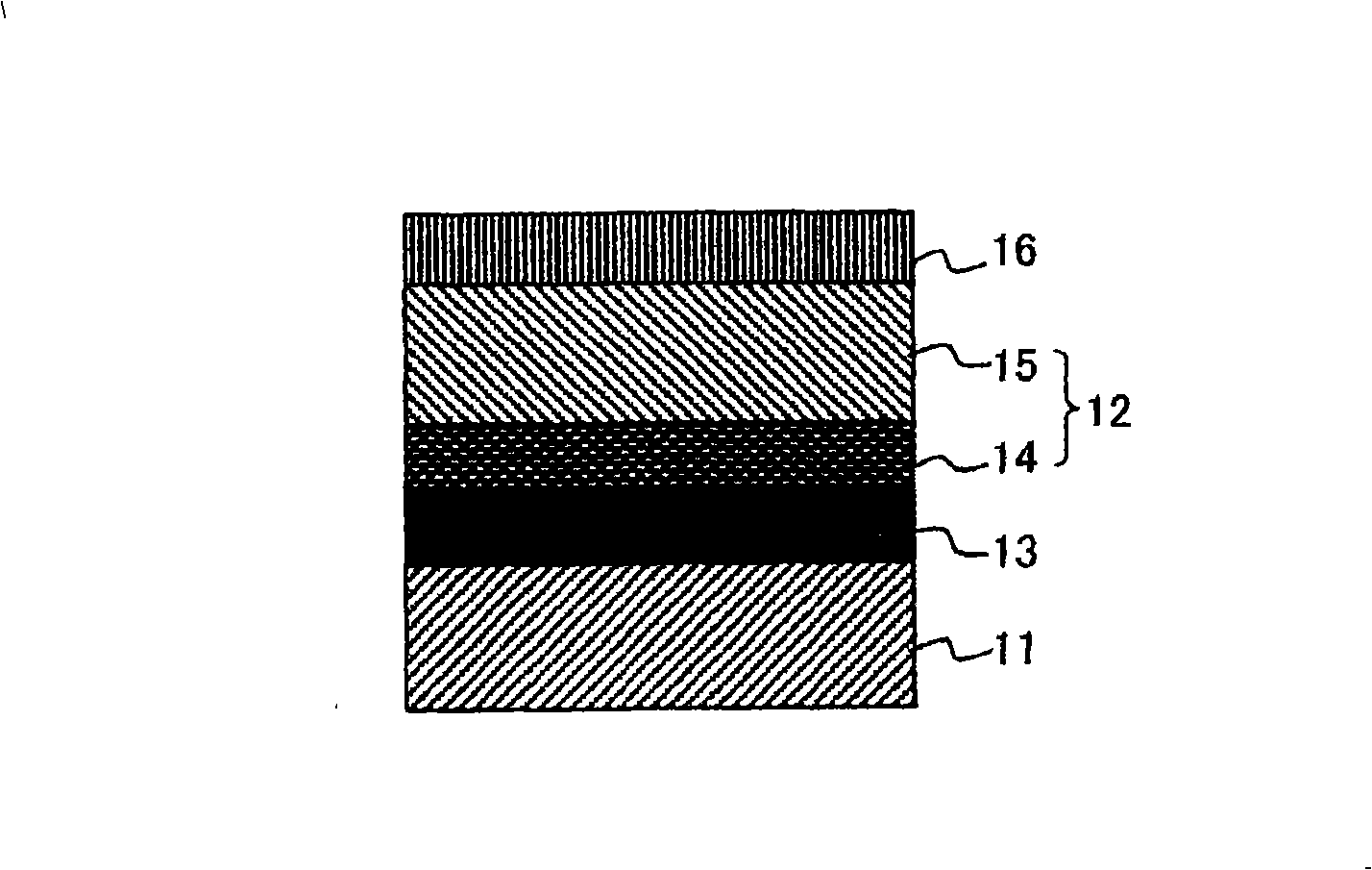

Embodiment 1

[0299] First, 100 parts by weight of zinc oxide (number-average particle diameter of 70 nm, test product manufactured by Tayca Corporation) and 500 parts by weight of toluene were mixed under agitation. Then, add 1.5 parts by weight of silane coupling agent (KBM603 TM , manufactured by Shin-Etsu Chemical Co., Ltd.), and the mixture was stirred for 2 hours. After toluene was distilled off under reduced pressure, the residue was baked at 150° C. for 2 hours.

[0300] 60 parts by weight of zinc oxide through the above surface treatment, 15 parts by weight of blocked isocyanate (Sumidule 3175 TM , manufactured by Sumitomo Byer Urethane Co., Ltd.), 15 parts by weight of butyral resin (BM-1 TM , manufactured by Sekisui Chemical Co., Ltd.) and 85 parts by weight of methyl ethyl ketone were mixed together to obtain a liquid mixture.

[0301] 38 parts by weight of the liquid mixture obtained above were mixed with 25 parts by weight of methyl ethyl ketone, and dispersed in a sand mil...

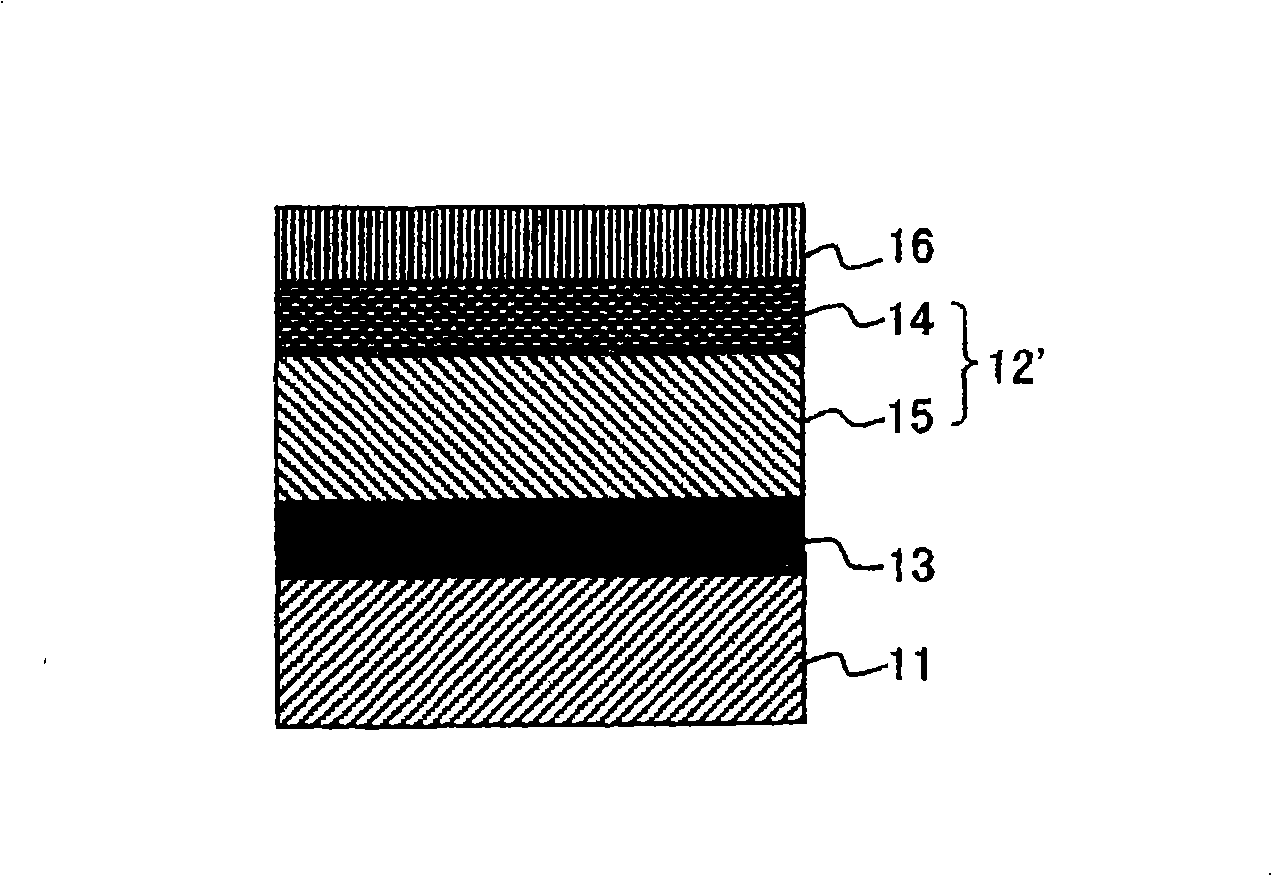

Embodiment 2

[0314] The electrophotographic photoreceptor of Example 2 was manufactured in the same manner as in Example 1 except that the thickness of the intermediate layer in Example 1 was adjusted to 19 μm.

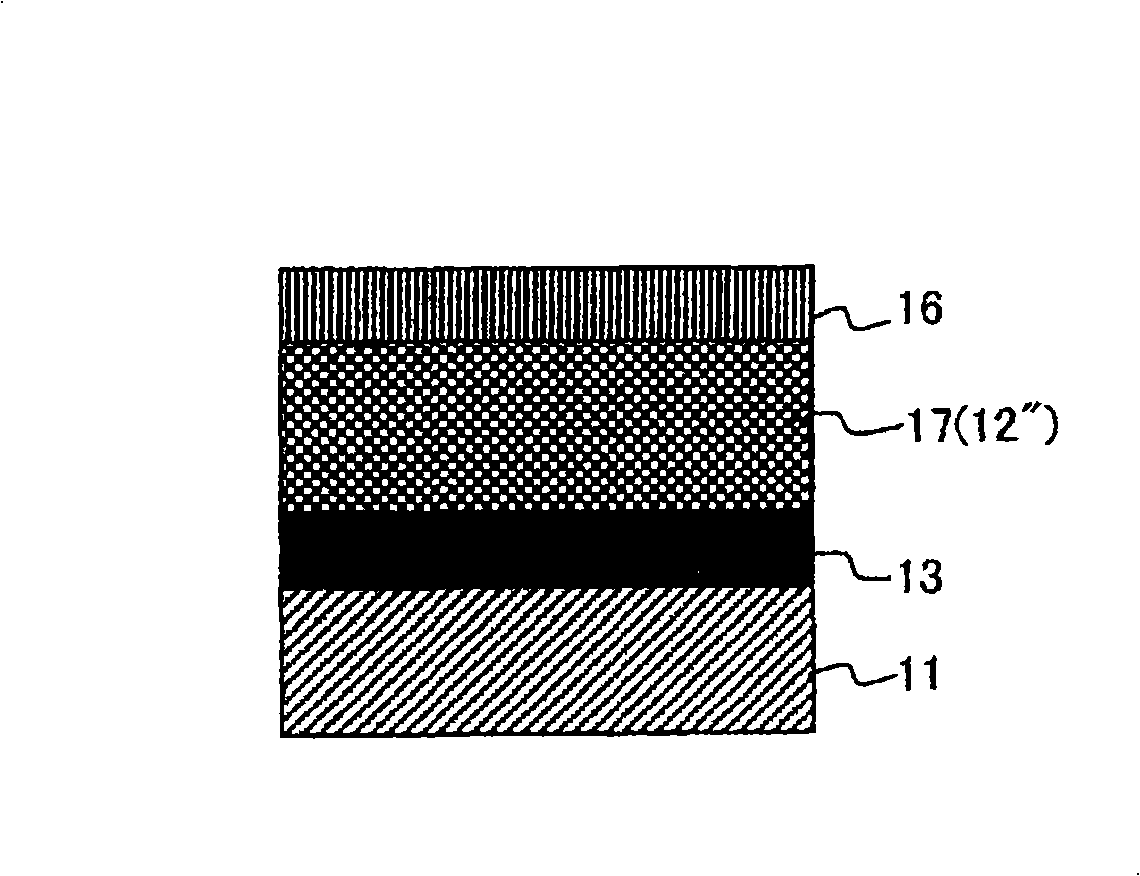

Embodiment 3

[0316] The electrophotographic photoreceptor of Example 3 was produced in the same manner as in Example 2, except that the ten-point average surface roughness R ZJIS94 An aluminum-based material (conductive support) of 0.15 μm (formed by changing the cutting conditions in Example 2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com