Machine for lifting earth wire of ultrahigh-tension power transmission line

A technology for lifting high-voltage transmission lines and ground wires, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of easy slipping out of the cross-arm head, increased costs, and high labor intensity, so as to improve the ability to resist risks and reduce maintenance costs , Easy to use and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

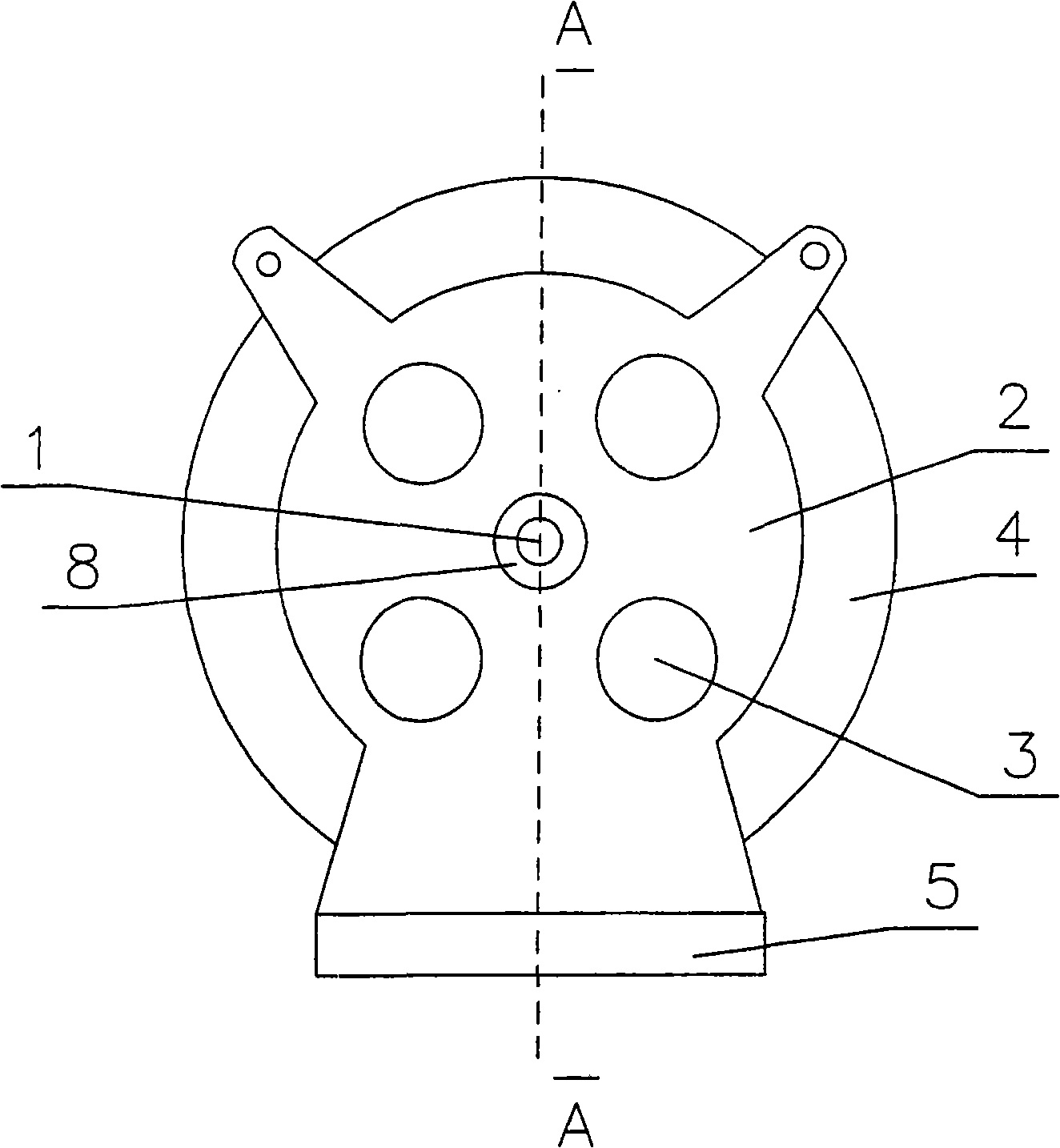

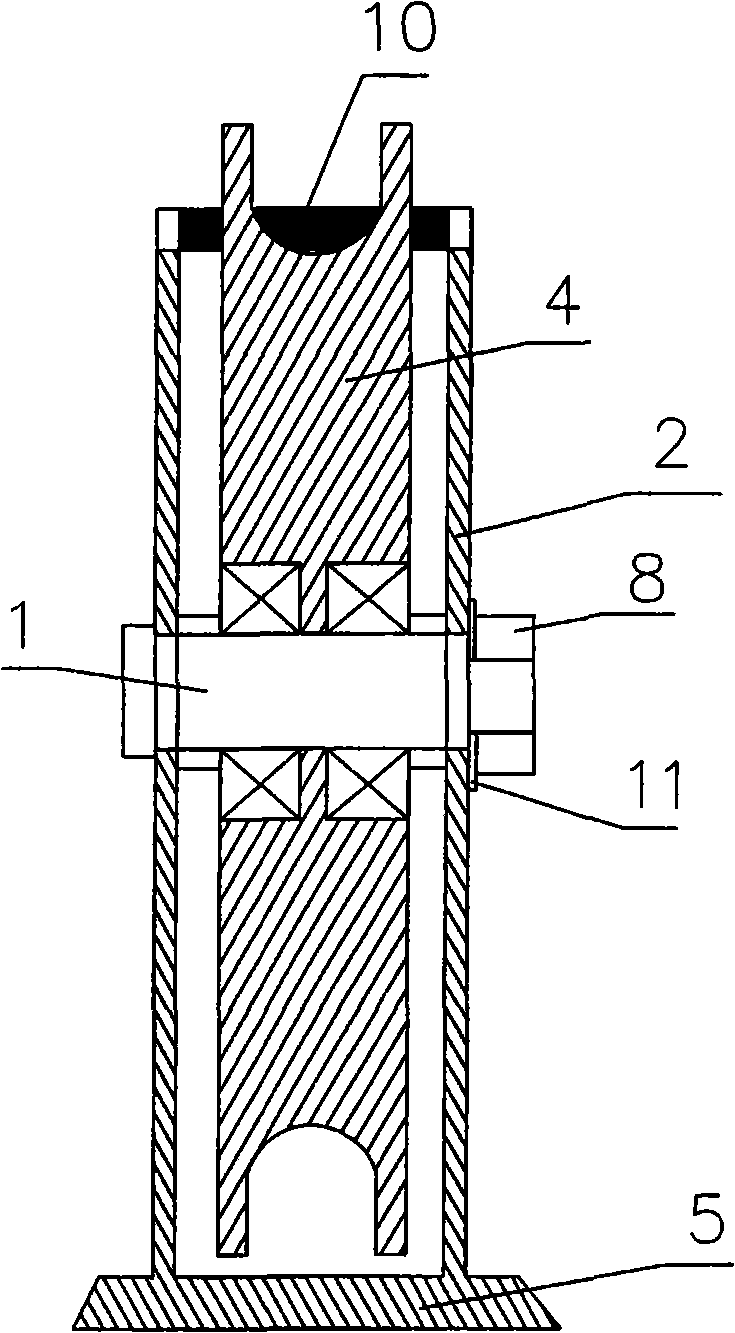

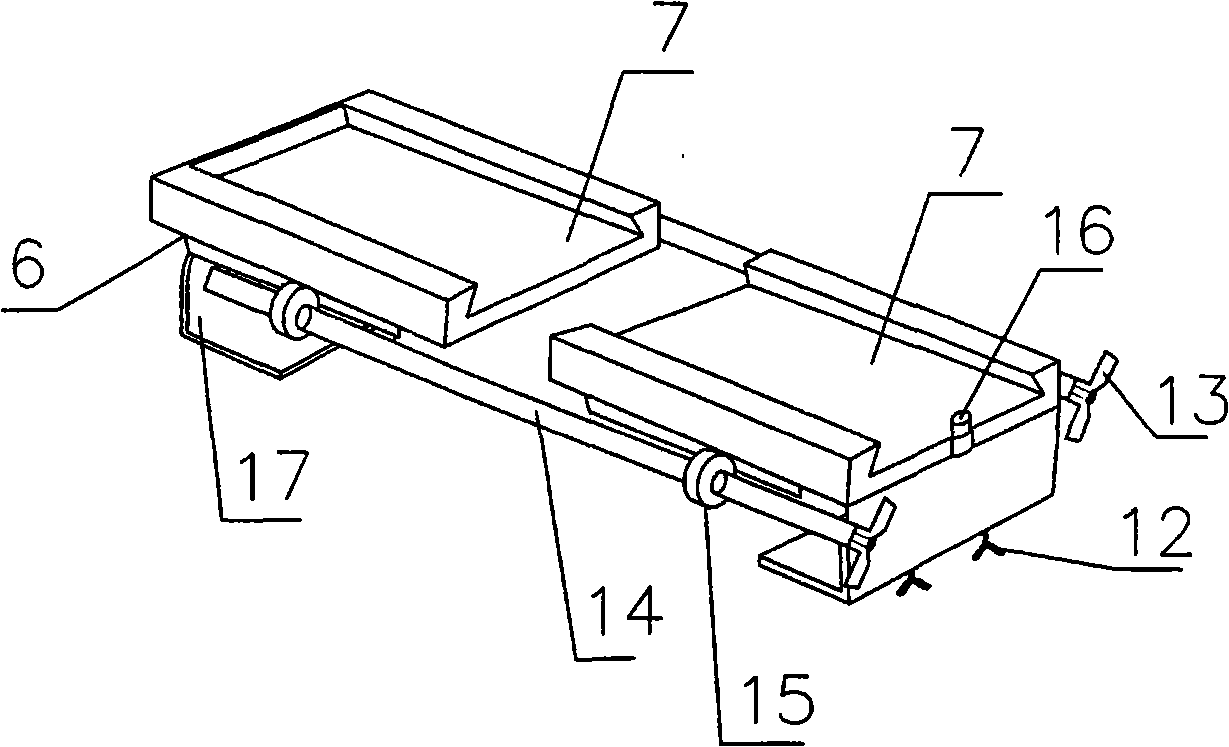

[0024] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a base 6 installed on the cross-arm head above the erection tower, an external support frame 2 installed on the base 6, and an external support frame 2 that is installed in its external support frame 2 and can be free in the vertical direction. Rotating pulley 4, and pulley 4 is a disc-shaped roller and is provided with a groove for the insulation single rope to move along the circumferential direction. That is to say, the structure of the base 6 corresponds to the structure of the cross-arm head of the different tower-shaped erecting poles installed therein. According to the structure of the cross-arm head, the base 6 of the corresponding structure is selected to be installed on it, and the base 6 Corresponding supporting fasteners are arranged on the top. In the actual operation process, the base 6 is first fixedly installed on the cross-arm head above the overhauled pole tower, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com