Absorbent breast pad and manufacturing method for the same

A liner and breast milk technology, applied in brassieres, absorbent pads, breast bandages, etc., can solve the problems of troublesome operation and low production efficiency, and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

[0101] In addition, since the following embodiments are preferred specific examples of the present invention, various technically preferable limitations are added. However, as long as there is no description intended to limit the present invention in the following descriptions, the scope of the present invention It is not limited to these embodiments.

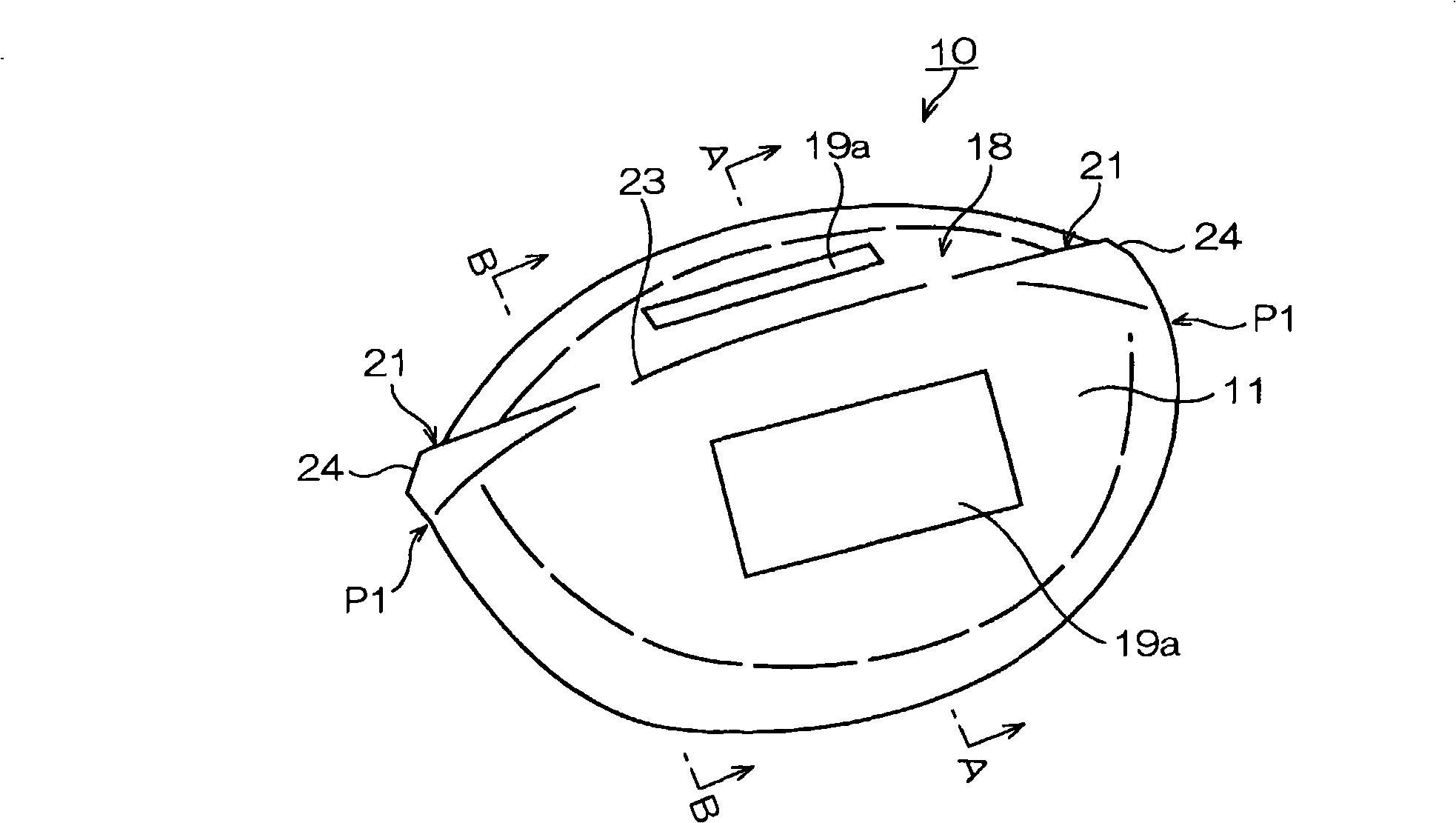

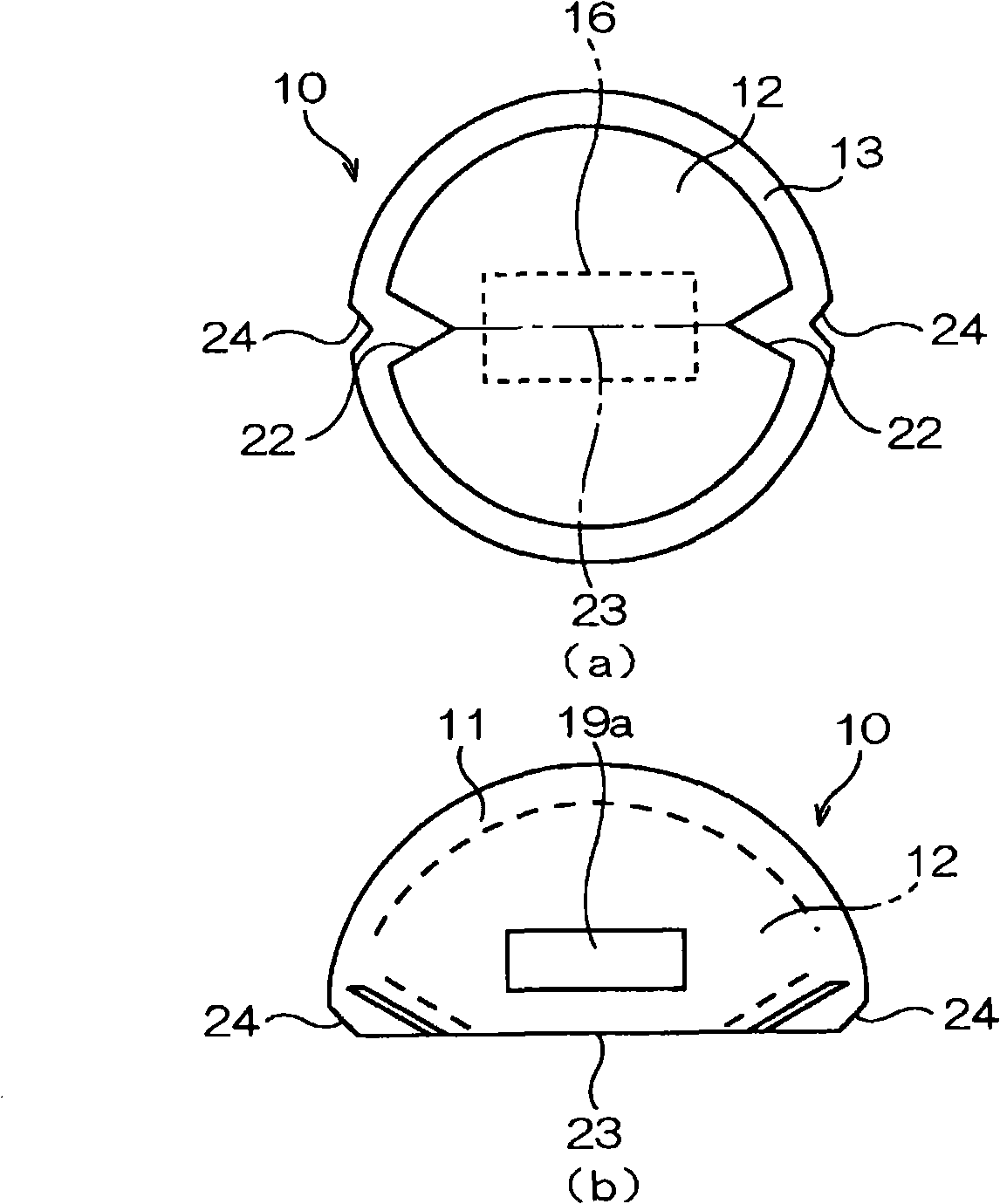

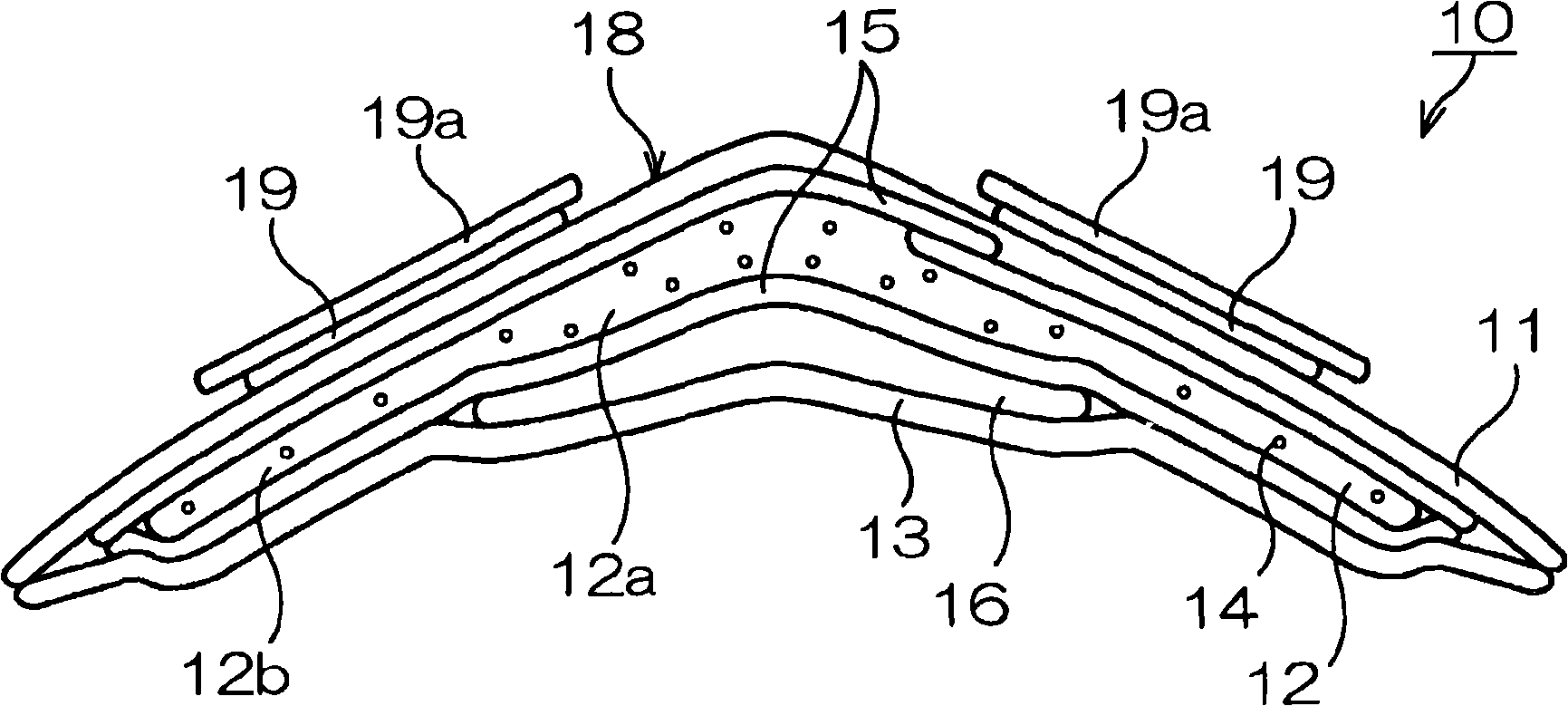

[0102] figure 1 It is a perspective view seen from the outside of the breast milk liner according to the first embodiment of the present invention, figure 2 (a) is figure 1 The unfolded diagram of the breastmilk liner, figure 2 (b) is figure 1 A schematic diagram of the folded state of the breastmilk liner, image 3 is along figure 1 The sectional view of the A-A line cut, Figure 4 is along figure 1 A cross-sectional view taken along line B-B.

[0103] The structure of the breastmilk liner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com