Method for producing three-dimensional contouring food product with rapid prototyping technology

A three-dimensional, prototype technology, applied in food forming, food preparation, dough forming machinery or equipment, etc., can solve the problems of slow production speed and insufficient three-dimensional sense, and achieve the effect of improving the fun of life and saving production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

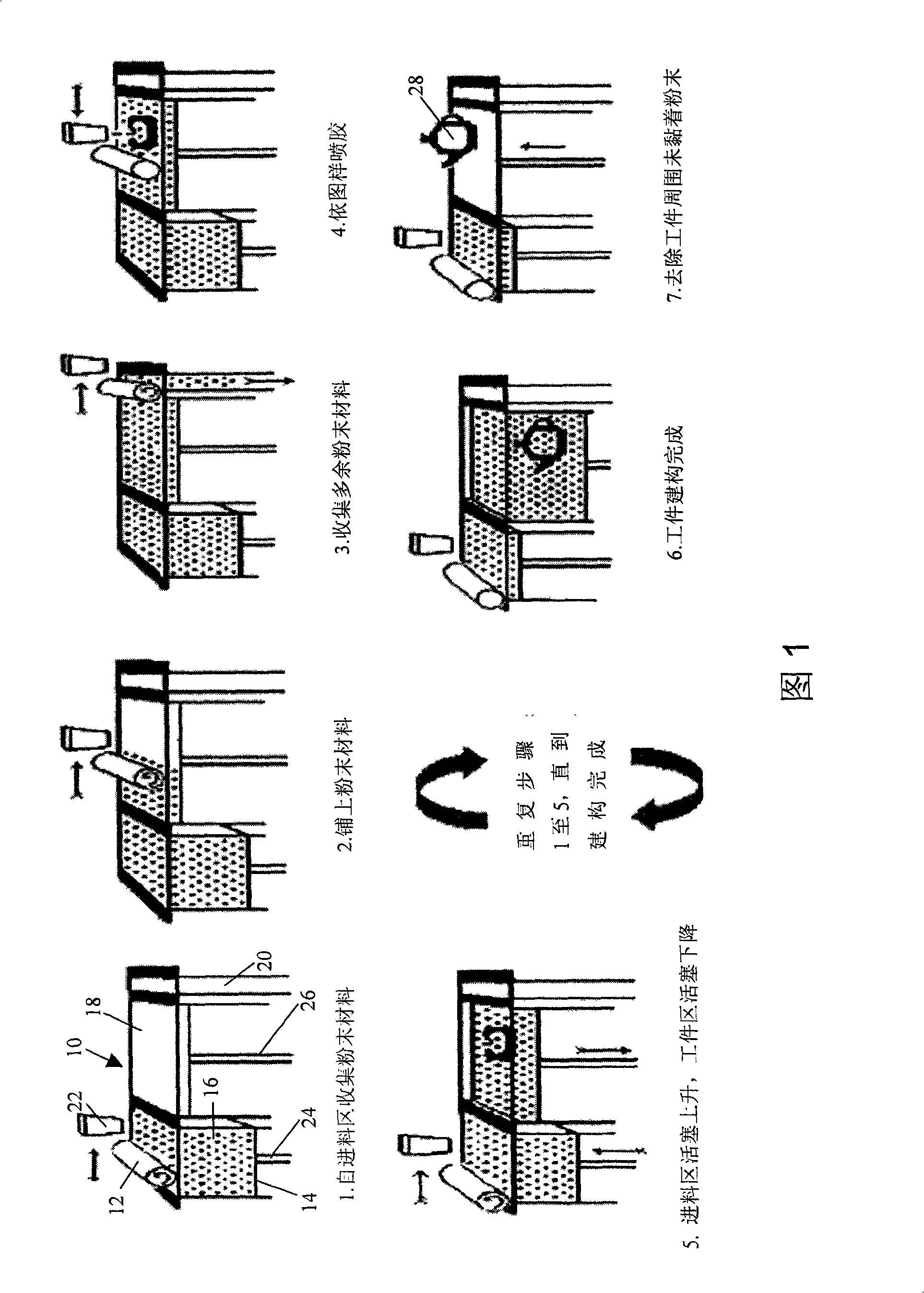

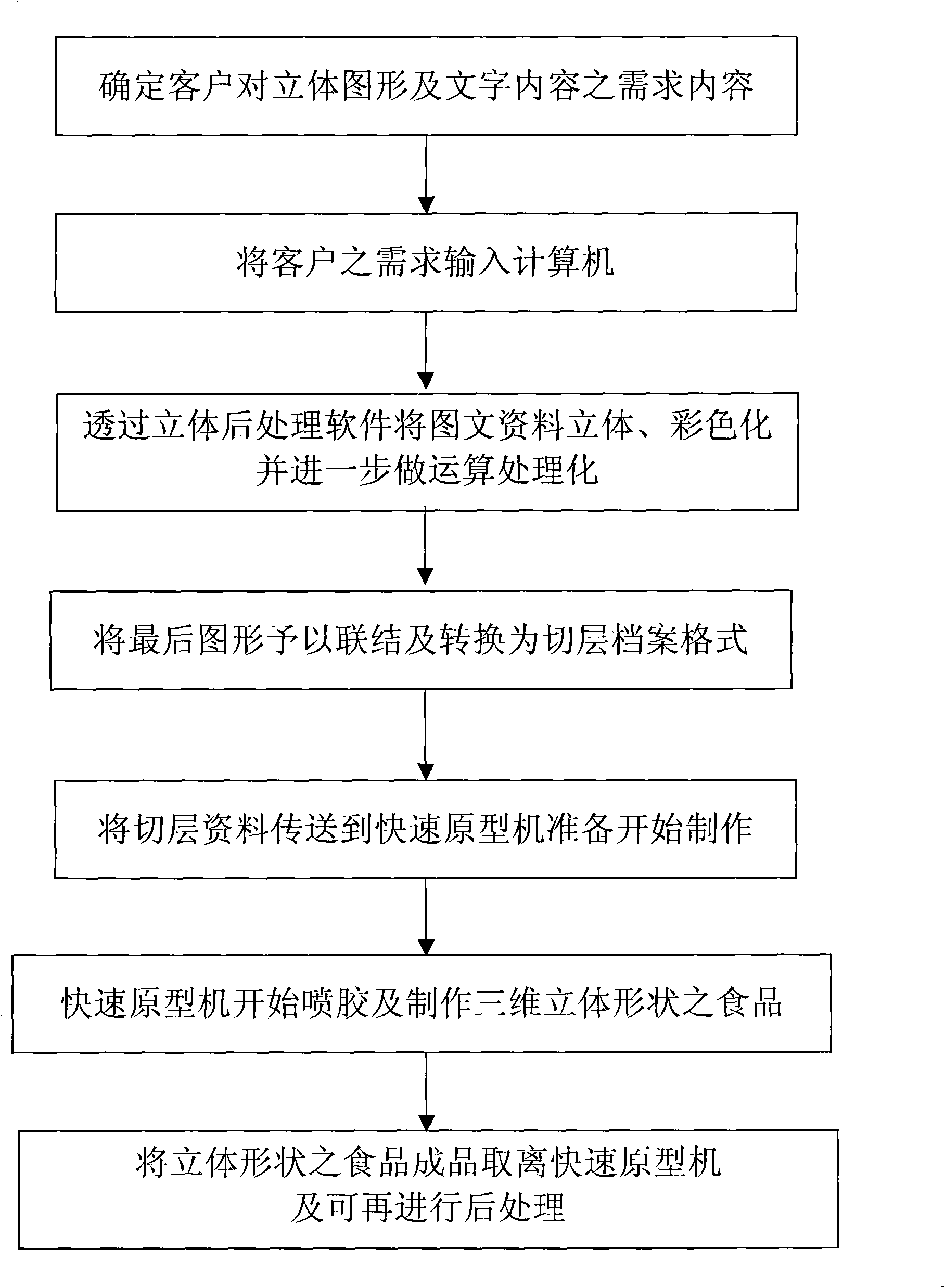

[0031]The technology used in the present invention has some similar situations to the research on rapid prototyping in the early days of the Massachusetts Institute of Technology. ,387,380, USPN5,902,441. However, the content of the above patent cases mostly focuses on the research of three-dimensional molding method technology and its equipment. The powder materials used are still under development, and the scope of the technology used is completely different from that of the food industry. It has nothing to do with it, moreover, it is not possible to immediately produce three-dimensional food with the original foreign technology. Therefore, it can be seen that the present invention combines the rapid prototyping technology with the food industry, and then develops a new three-dimensional food manufacturing method, which is an unprecedented pioneering work. Based on the above, the present invention does not presuppose a position from the beginning, does not analyze the compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com