Spray head of dust catcher

A sprinkler head and dust collector technology, which is applied in the mechanical field, can solve the problems of complex overall structure of the sprinkler head, affect the dust removal effect, and inconvenient installation, and achieve the effect of good dust removal effect, improved uniformity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

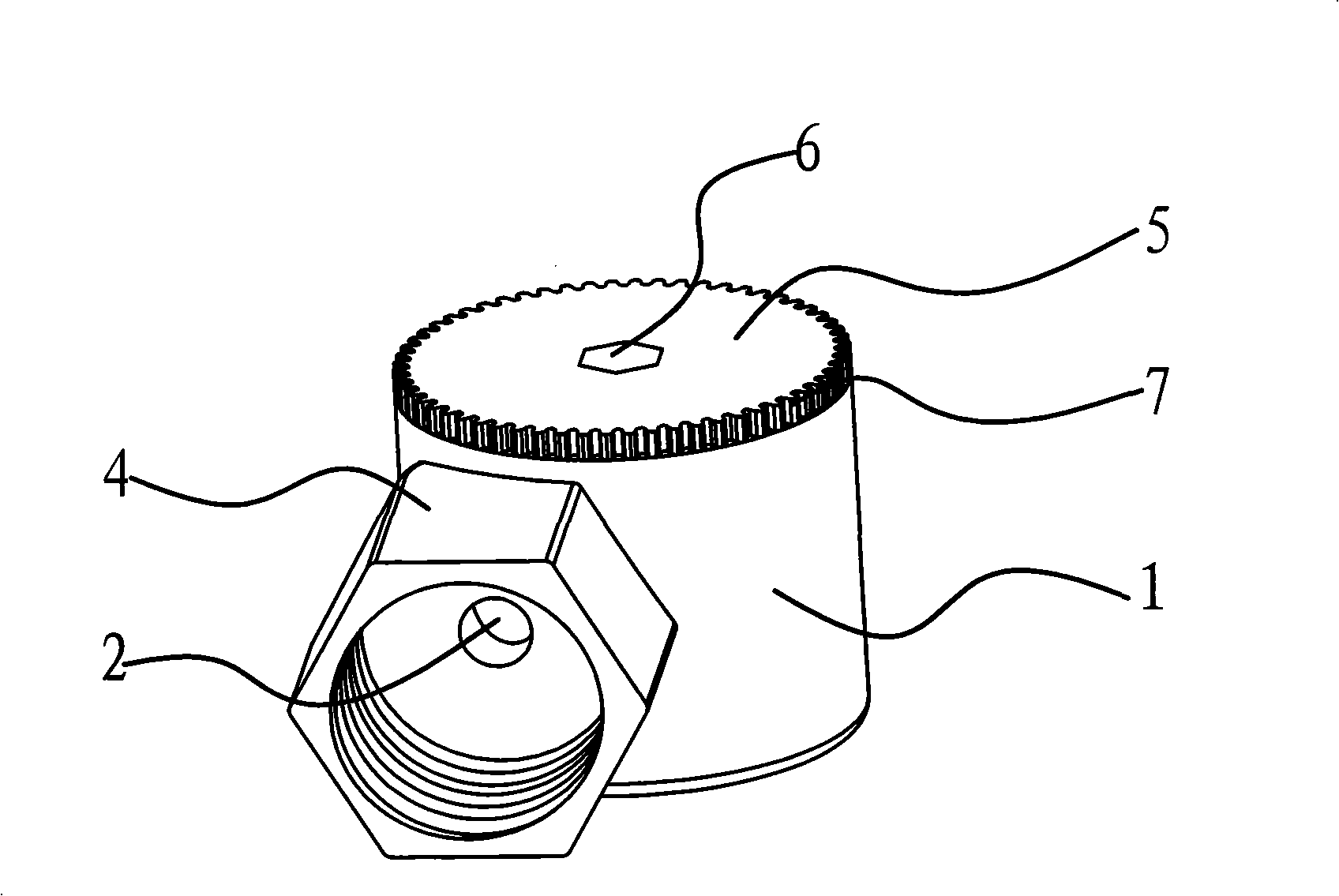

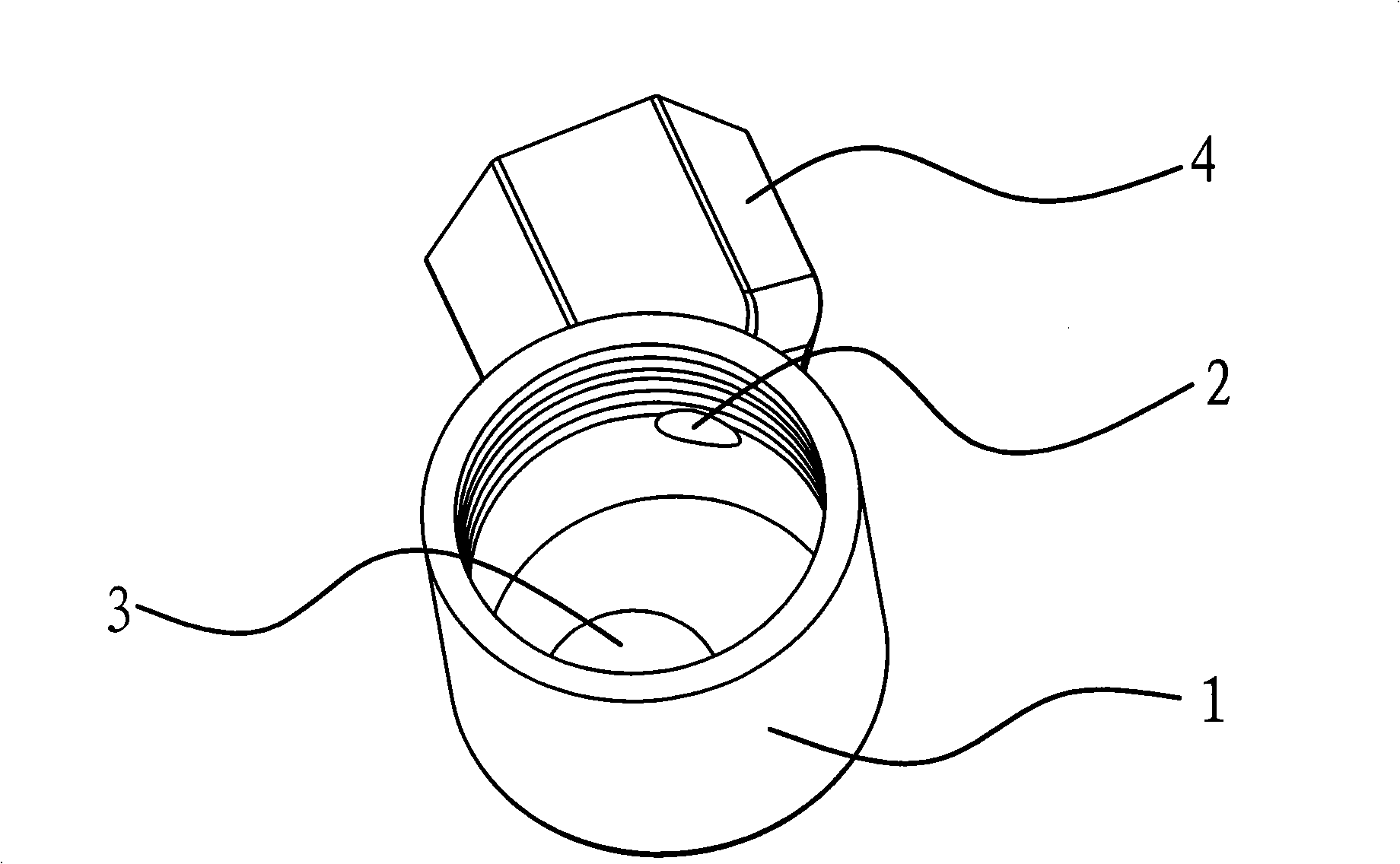

[0024] The sprinkler head is a device used for industrial dust removal. The sprinkler head is installed in the dust collector, and the water sprayed by the sprinkler head is in the form of water mist and sprays the airflow, and the dust or dust in the airflow is sprayed. The solid particles are fully absorbed and settle to the bottom of the dust collector, so as to achieve the purpose of dust removal. This device is made up of spare parts such as nozzle body 1 and nozzle cap 5.

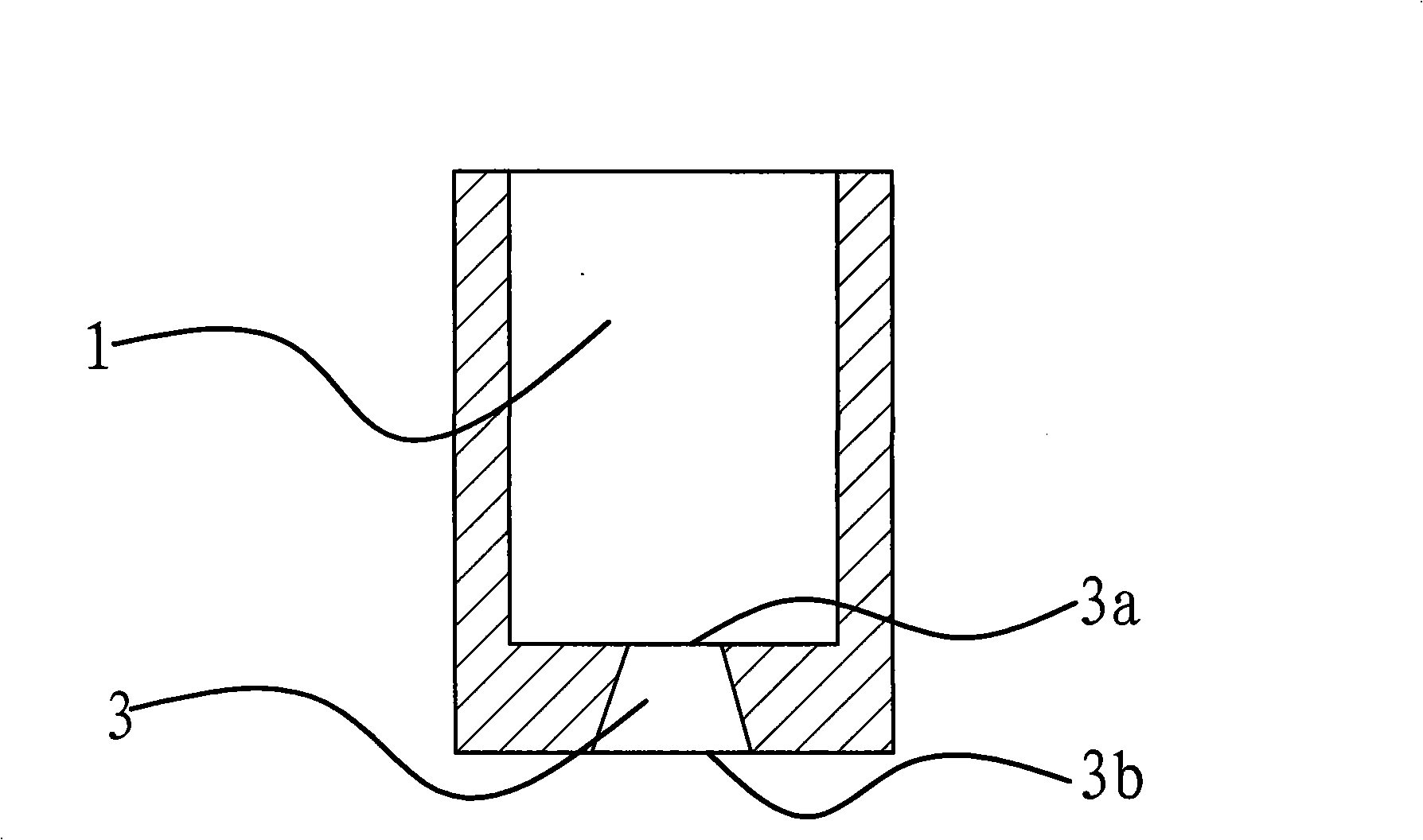

[0025] Specifically, as figure 1 and image 3 As shown, the nozzle body 1 is cylindrical and the side wall in the inner cavity of the nozzle body 1 has a certain radian. There is a connecting pipe 4 communicating with the straight water hole 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com