Catalytic cracking absorption stabilization system having gasoline cutting and process producing more propene and reducing alkene

An absorption stabilization system and catalytic cracking technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problems of decreased gasoline yield, high content of carbon five components, increased process energy consumption, etc., and achieve the reduction of gasoline olefin content. , The effect of improving the quality of gasoline products and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

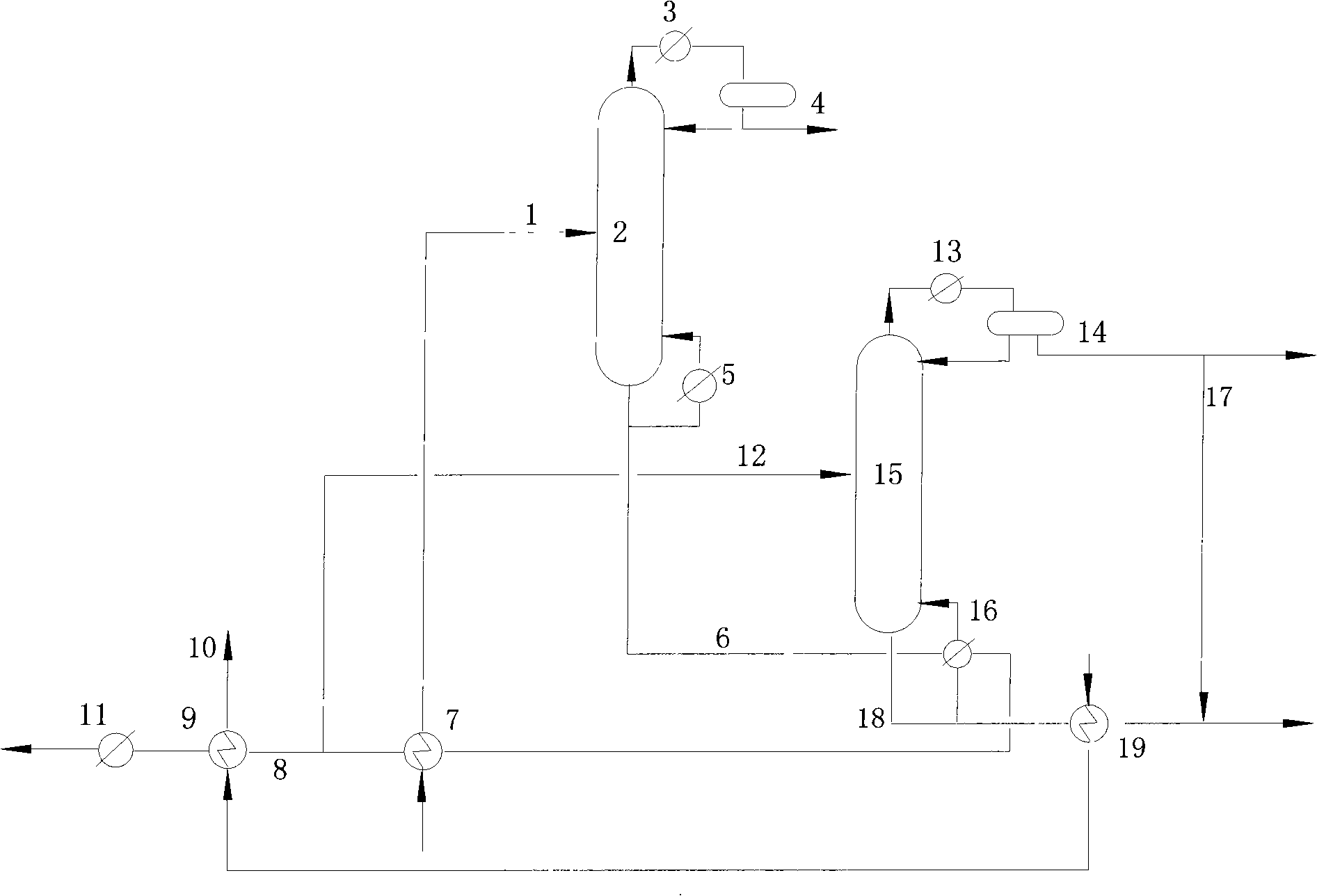

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0021] Taking an oil refinery with a catalytic processing capacity of 1.5 million tons per year as an example for simulation, the compressed rich gas capacity is 142.5 t / h, and the naphtha flow rate is 113.6 t / h. The rich gas is compressed by the compressor, and the compressed rich gas is mixed with the rich absorption gasoline at the bottom of the absorption tower and the desorption gas at the top of the desorption tower, condensed by the condenser to 60°C and enters the balance tank. After the vapor-liquid balance, the rich gas enters the absorption tower , in order to reduce the absorption temperature, use the intermediate pump to circulate the heat released during the absorption process, the lean gas from the top of the absorption tower enters the reabsorption tower, and the light diesel oil produced from the main fractionation tower is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com