Composite charging condensation shock wave fire-fighting bomb

A fire-extinguishing bomb and cold-shock technology, applied in the field of fire-extinguishing, can solve the problems of poor atomization effect, destroy the fire field flow field, increase the fire field energy, etc., and achieve the effect of improving the atomization effect, reducing the surface tension, and reducing the fire field temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

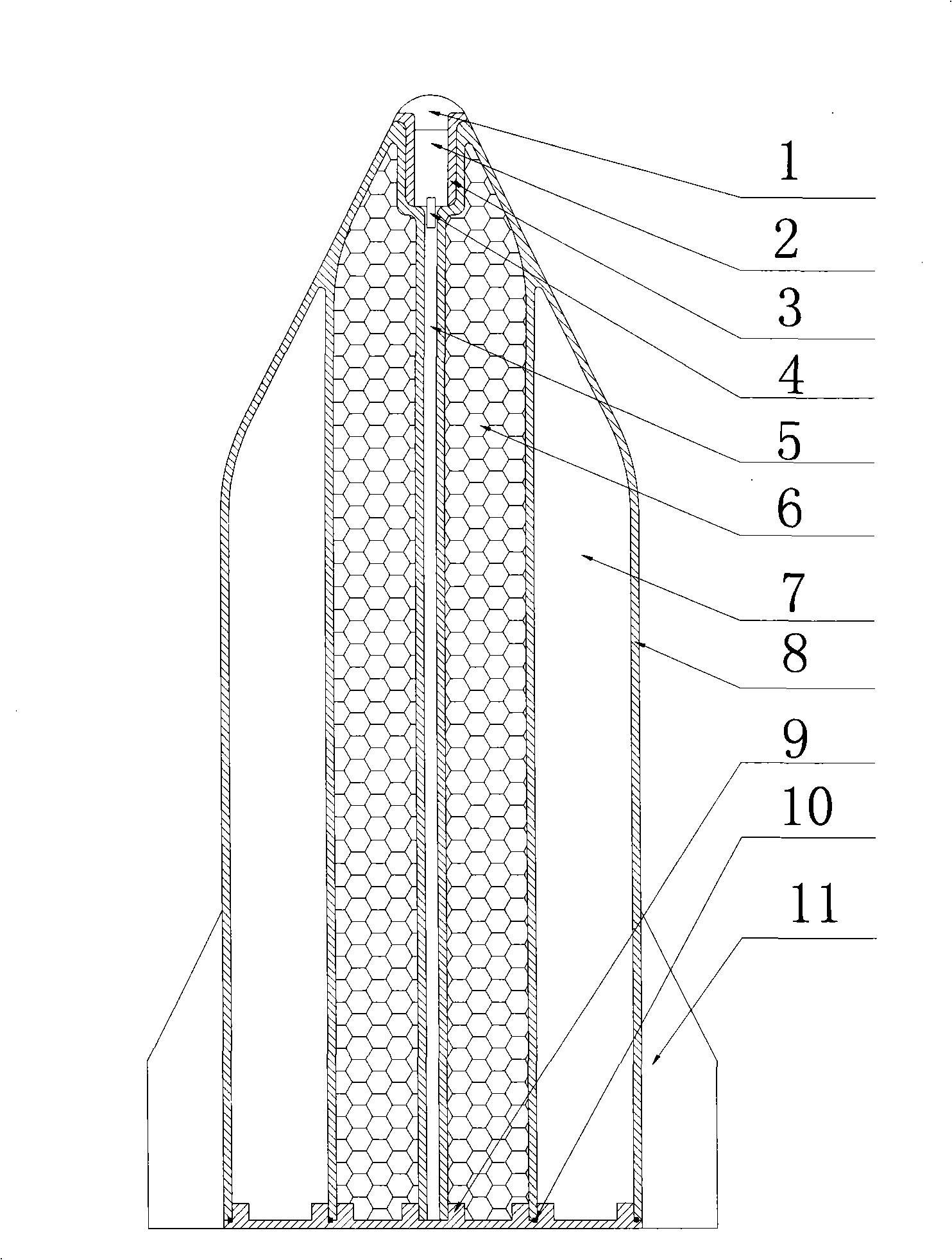

[0015] see figure 1 , the shell 8 of the composite charge structure fire extinguishing bomb of the present embodiment is formed by blow molding of flame-retardant material, and its exterior is cylindrical, and the head is conical, and the central hole is stepped with the upper part larger and the lower part smaller. The central hole is used to fill low-energy explosive spraying powder, and the large hole on the top is built with a fixed sleeve 3, which is threadedly connected with the housing 8. A fuze device 1 and a firing device 2 are sequentially arranged in the fixed sleeve 3 , and both are closely matched with the fixed sleeve 3 and fixed. The lower end of the high-safety detonator 4 is inserted in the explosion line 5 made of low-energy explosive spraying powder, and its upper end is in contact with the firing device 2 . The cavity for containing the fire extinguishing material is two annular cavities, the powder fire extinguishing material 6 is contained in the inner a...

Embodiment 2

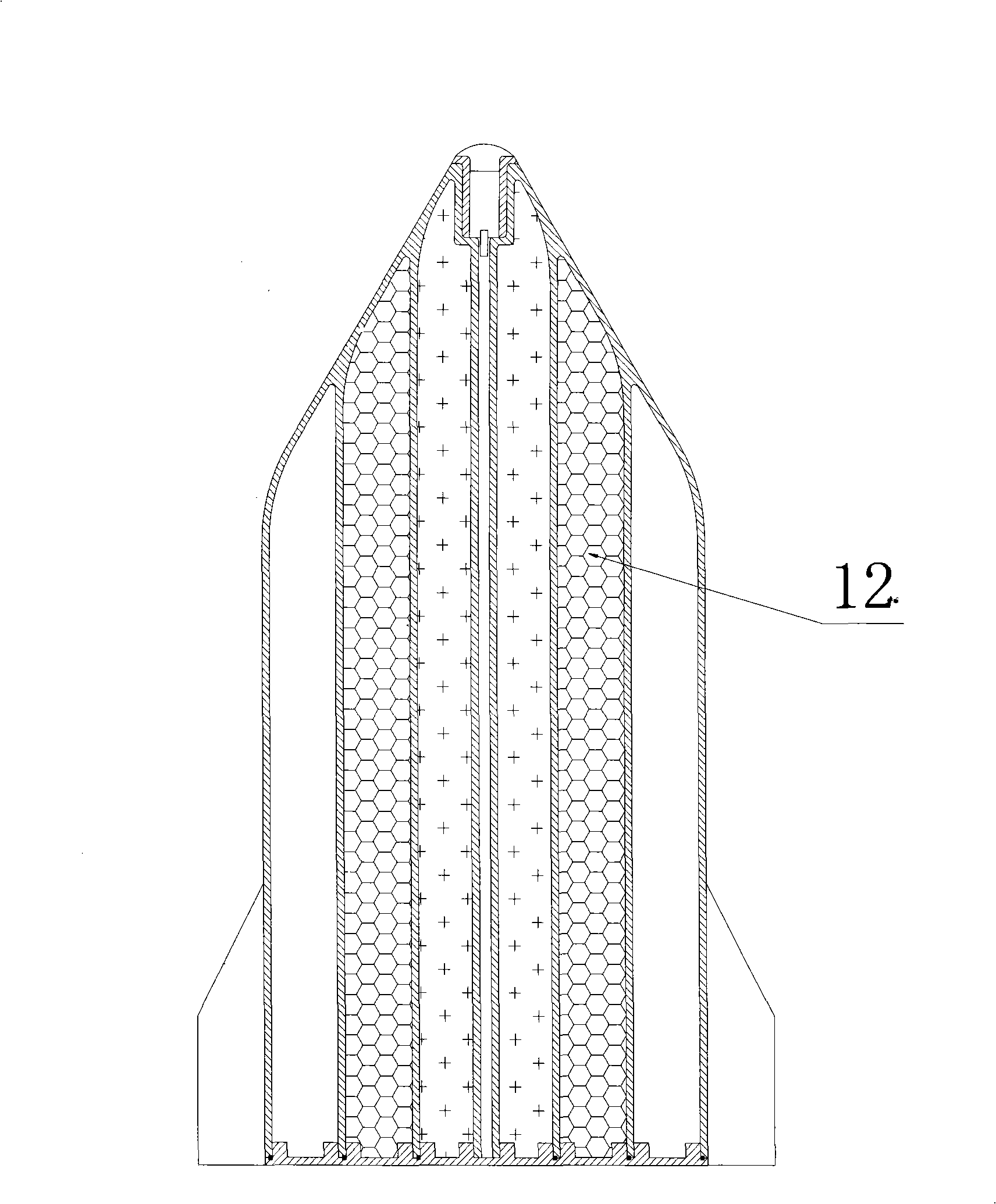

[0017] see figure 2 In this embodiment, the annular cavity containing the fire extinguishing material is divided into three, and the volume ratio between the central hole and the inner annular cavity, the middle annular cavity, and the outer annular cavity is 1:30:70:140, which can be Determine the type of charge in each annular cavity according to the nature and characteristics of the fire field, so as to extinguish the fire more effectively. For example, metal salt solution, foam fire extinguishing agent and dry powder fire extinguishing agent are respectively contained in the three cavities. Compared with Embodiment 1, this embodiment adds a middle annular cavity 12, and the rest of the structure is substantially the same as that of the embodiment.

[0018] In order to demonstrate the actual use effect of the present invention, adopt such as figure 1 The cold shock wave fire extinguishing bomb with double-layer composite charge structure shown in the fire extinguishing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com