Electrolytic cell for quartz crystal microbalance / electrochemical quartz crystal microbalance

A quartz crystal and microbalance technology, applied in the field of electrolytic cells, can solve the problems of affecting the accuracy, reducing the accuracy of experimental results, uneven solution concentration, etc., and achieving the effects of improving controllability, simple production and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

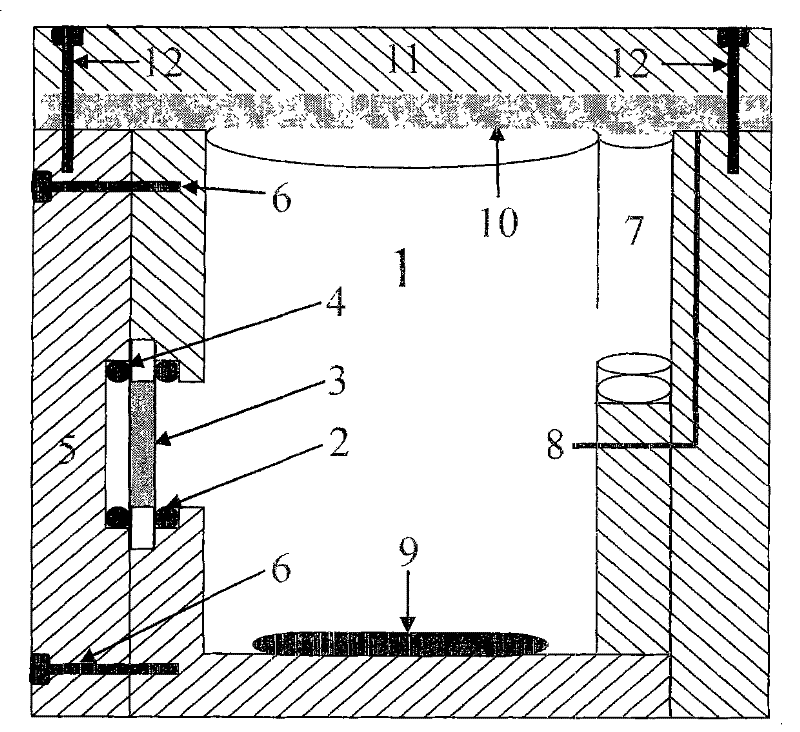

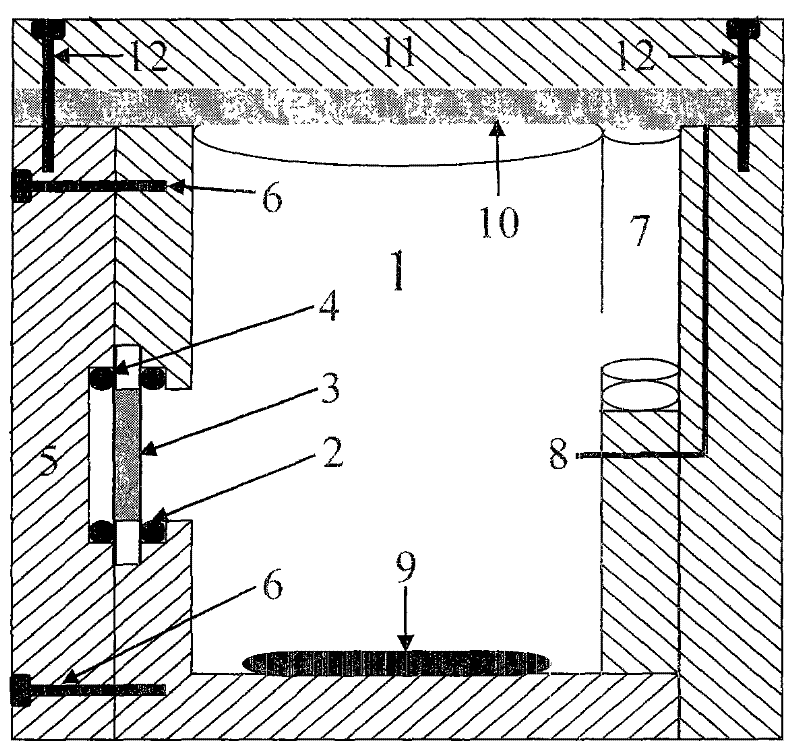

[0017] like figure 1 As shown, an electrolytic cell used for a quartz crystal microbalance, the inner wall of the cell body 1 of the electrolytic cell is provided with a reference electrode slot 7 . A platinum wire counter electrode 8 in contact with the space inside the cell is embedded on the body wall of the electrolytic cell. The side of the cell body 1 of the electrolytic cell is provided with a baffle plate 5 communicating with the space in the cell, and the inside of the cell body 1 and the middle part of the side baffle plate 5 are provided with a rubber sealing ring 2 , a quartz crystal vibrating plate 3 and a rubber sealing ring 4 . The two incoming and outgoing lines of the quartz crystal oscillator plate 3 pass through the slits of the side baffle 5 and the pool wall, and then the side baffle 5 and the pool wall are fixed by the screw rod 6 . The inner bottom of the pool body 1 is provided with a stirring magnet 9, and the top of the pool body 1 is provided with a...

Embodiment 2

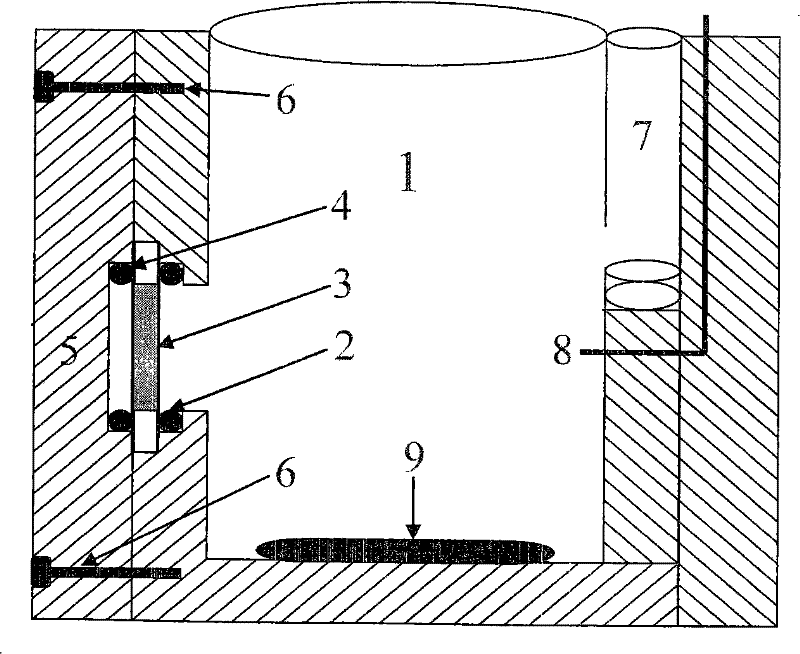

[0022] like figure 2 As shown, the electrolytic cell of the present invention can be used for the experimental measurement of the electrochemical quartz crystal microbalance, and has good versatility. unscrew figure 1 The screw rod 12 of the top cover plate 11 of the electrolytic cell is taken off the top cover plate 11 and the sealing plastic ring 10, and then it is a novel electrolytic cell of an electrochemical quartz crystal microbalance.

[0023] Electrolytic cell use process:

[0024] Unscrew the screw rod 6 that fixes the side baffle 5, take off the side baffle 5, and seal the quartz crystal oscillator plate 3 (a new quartz crystal oscillator plate is required for each experiment) with the rubber seal ring 2 and the rubber seal ring 4, and then The side baffle 5 is fixed to the pool wall by the screw rod 6 . A clean and suitable stirring magnet 9 is placed at the bottom of the cell body 1, and the electrochemical quartz crystal microbalance is connected with the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com