Honeycomb for an exhaust treatment unit

A technology for exhaust gas treatment and honeycomb body, which can be used in exhaust devices, thin material treatment, engine components, etc., and can solve the problems of honeycomb body function failure, brazing connection extension, and change of honeycomb body thermal expansion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

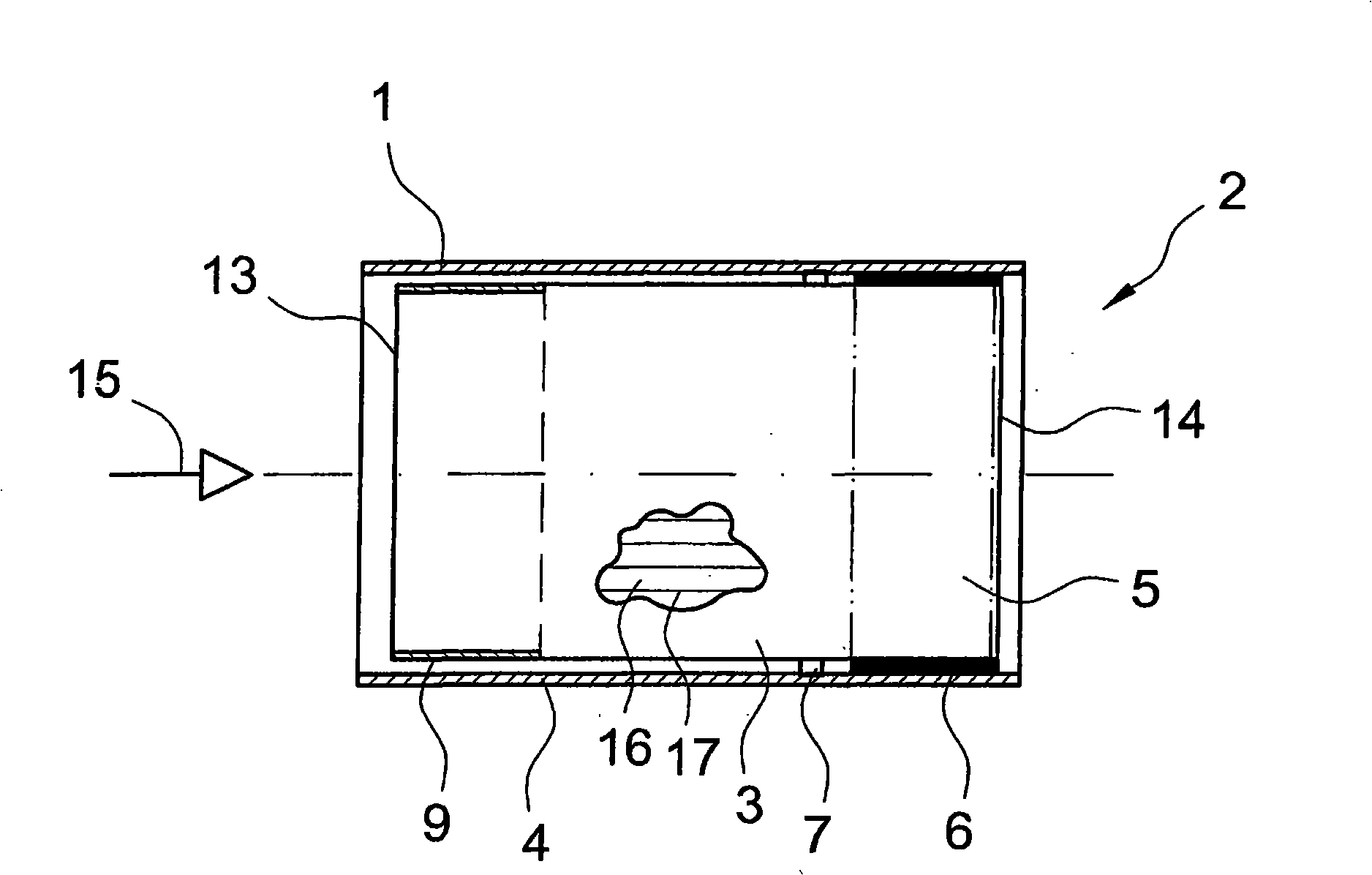

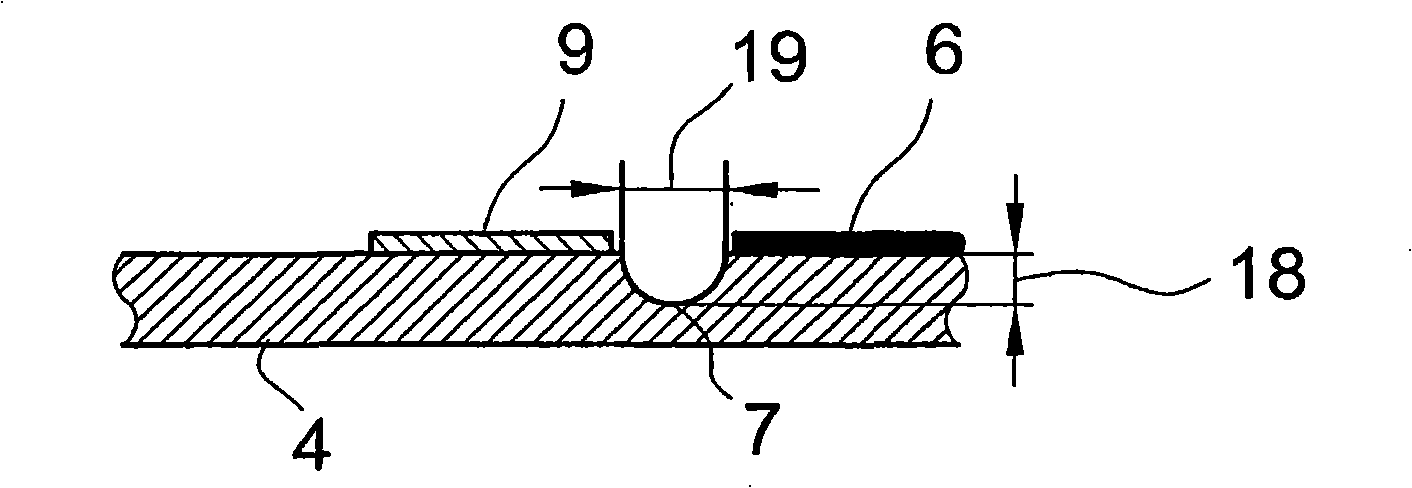

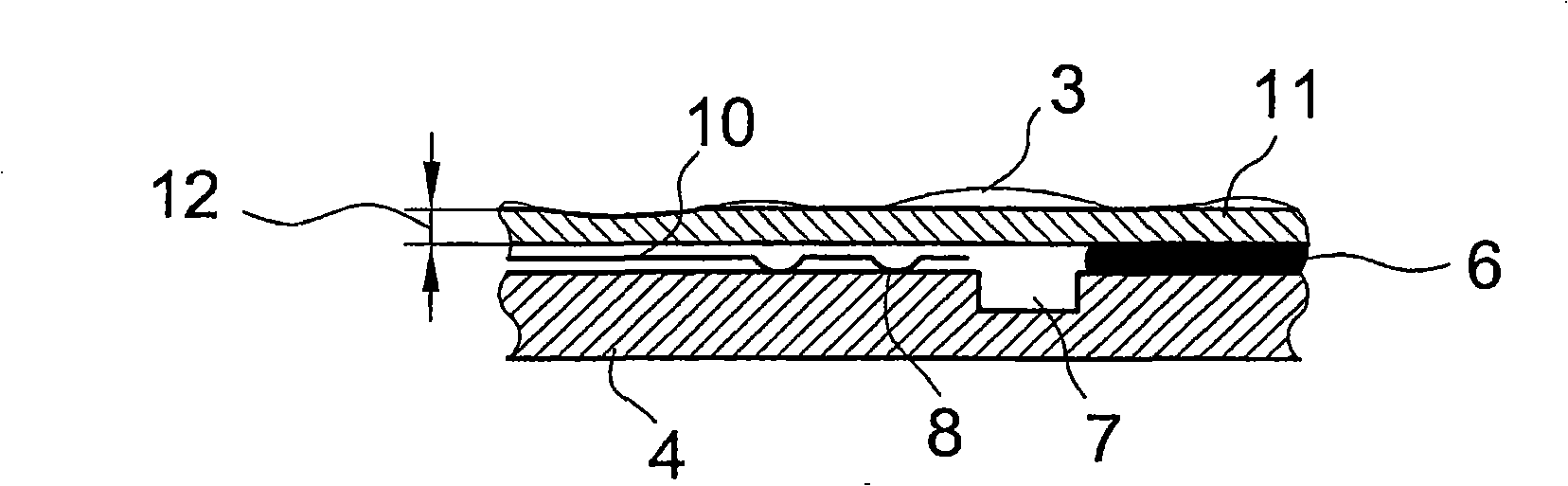

[0034] figure 1 A honeycomb body 1 for an exhaust gas treatment unit 2 is schematically shown in partial cross-section. The honeycomb body 1 comprises a honeycomb structure 3 and a housing 4 which completely surrounds the honeycomb structure 3 . A region 5 for forming a brazed connection 6 is provided between the honeycomb structure 3 and the housing 4 . Here, the region 5 of the brazed connection 6 is positioned closer to the second end face 14 than to the first end face 13 . In addition, the honeycomb body 1 has two different structures for delimiting the brazed connection 6 , namely a groove 7 formed circumferentially in the shell 4 and a ceramic material arranged on the outside near the first end face 13 of the honeycomb structure 3 . Coating9.

[0035] In order to produce such a honeycomb body 1 , the region 5 of the brazed connection 6 is first selected adjacent to the second end face 14 . It is then determined that the honeycomb structure 3 is inserted into the hous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com