Seedbed rotary cultivator for minimum-tillage precise combined direct seeder

A technology of rotary tillage device and live broadcast machine, which is applied in the direction of tillage machines, agricultural machinery and implements, shovels, etc. It can solve the problems of multiple production processes, insufficient rotary tillage depth, and soil erosion, so as to improve the level of moisture conservation, improve passability, The effect of preventing entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The design of this embodiment is applicable to the seedbed rotary tillage of no-tillage / less-tillage precision joint direct-seeding operation of rapeseed with the mulch of previous crops left. It is also suitable for the seedbed rotary tillage of no-tillage / less-tillage precision joint direct seeding operation of other crop seeds with the cover of previous crops left.

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

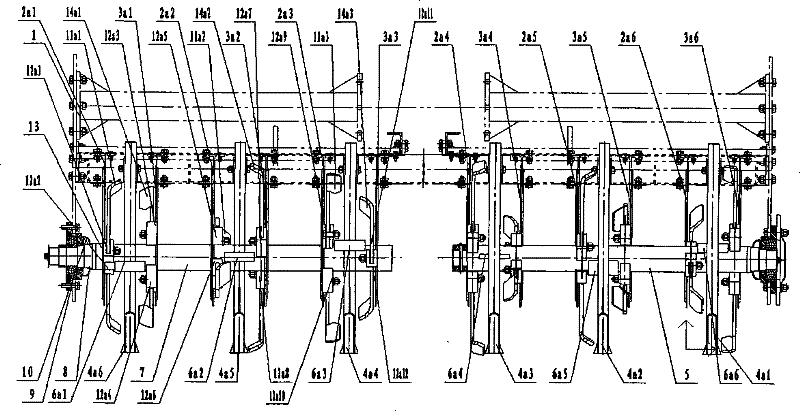

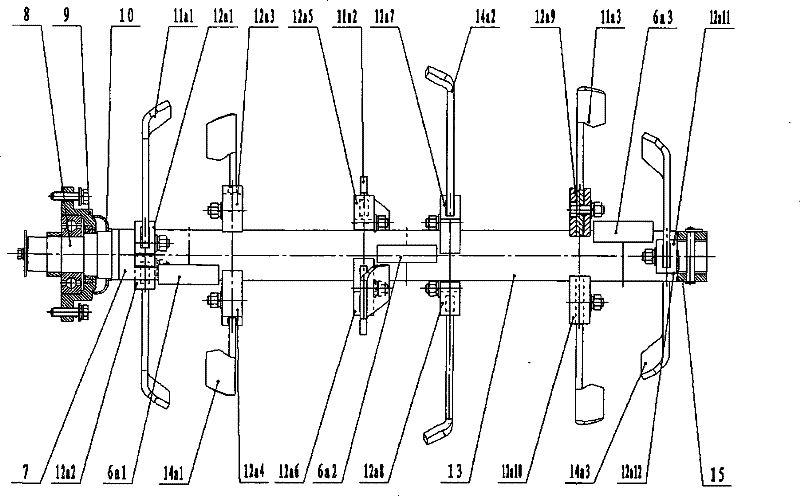

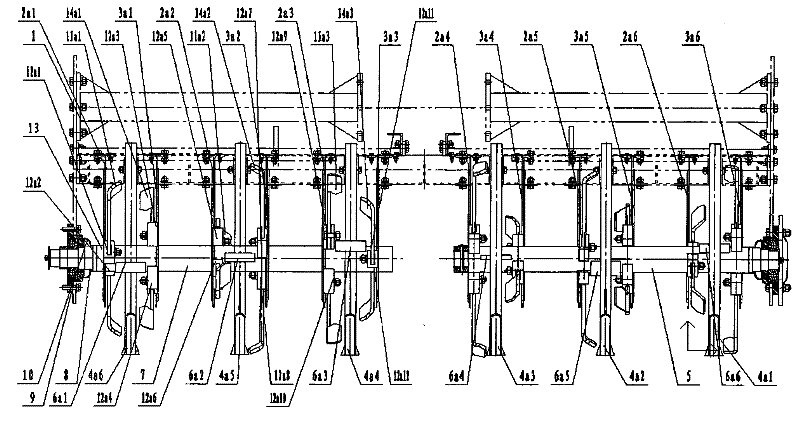

[0021] according to figure 1 , figure 2 It can be seen that a seed bed rotary tillage device of a rapeseed low-tillage precision combined direct-seeding machine includes the first to sixth seed bed left channel plates 2a1, 2a2, 2a3, 2a4, 2a5, 2a6; the first to sixth seed bed right channel plates Plates 3a1, 3a2, 3a3, 3a4, 3a5, 3a6; first to sixth ditching and fertilizing shovels 4a1, 4a2, 4a3, 4a4, 4a5, 4a6; right rotary tiller roller combination 5; first to sixth anti-winding blades 6a1, 6a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com