Dual-tower dust removal and desulphurization device

A desulfurization device and main tower technology, applied in the direction of using liquid separation agent, lighting and heating equipment, and separation of dispersed particles, can solve the problems of low dust removal and desulfurization efficiency, high cost, and high operating costs, and achieve high dust removal and desulfurization efficiency. Good environmental benefits and low operating costs

Active Publication Date: 2008-11-19

湘潭市南方高新技术研究院有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there are several shortcomings in the dust removal and desulfurization devices for coal-fired flue gas at home and abroad: first, the process equipment is complicated and the cost is high; second, the efficiency of dust removal and desulfurization is not high, and it is only suitable for small and medium-sized coal-fired boilers; High, not conducive to promotion and use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

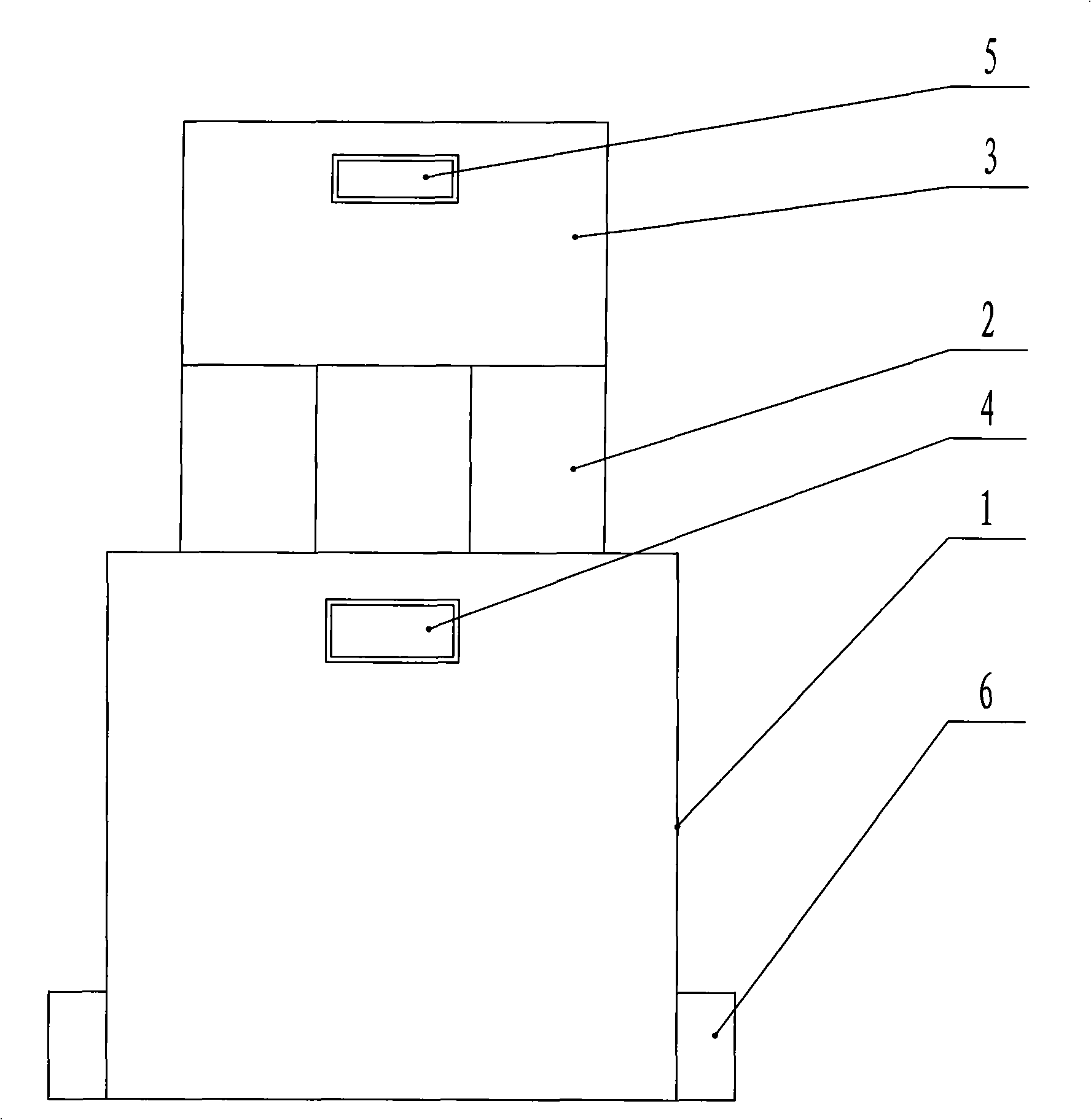

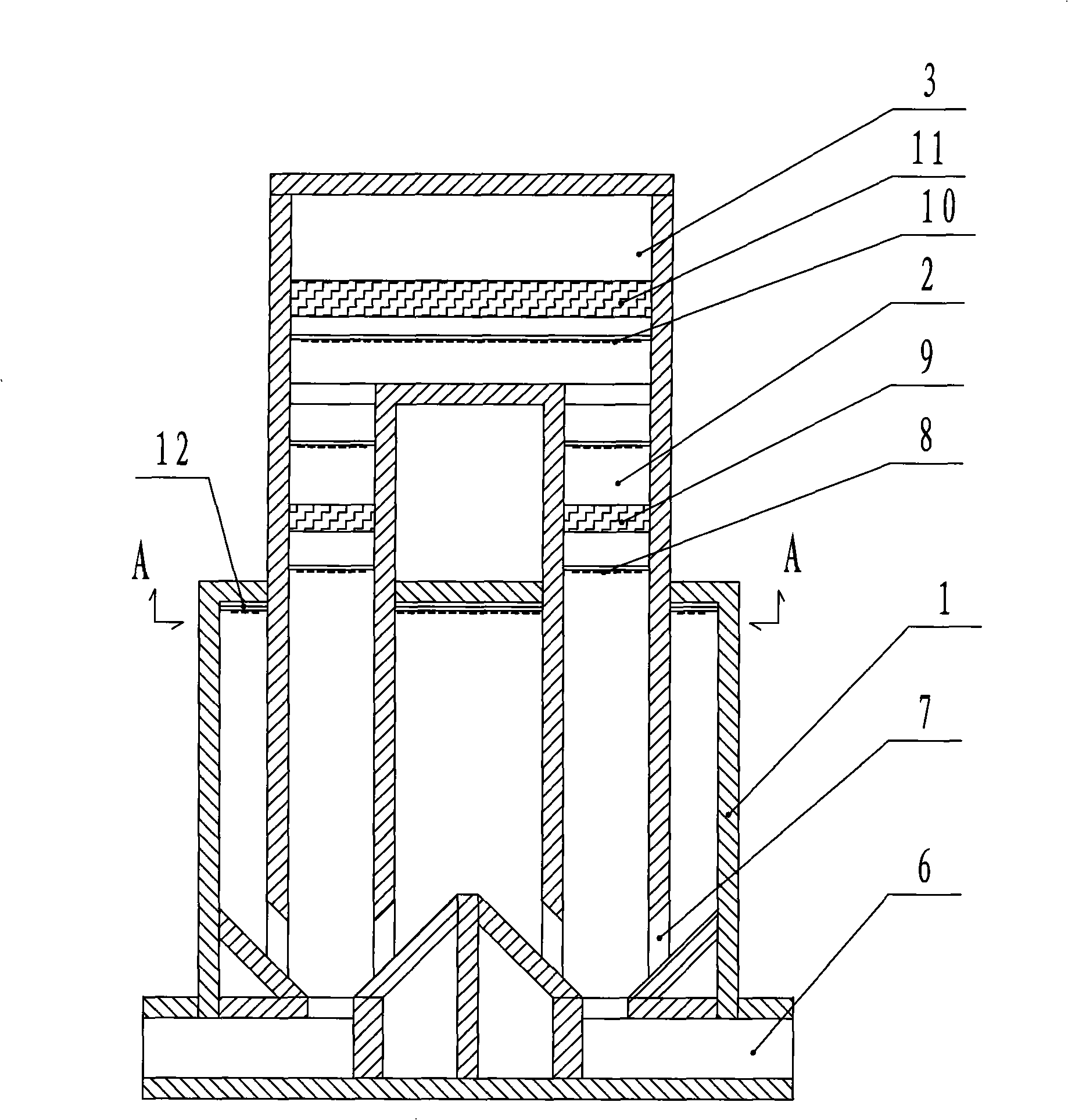

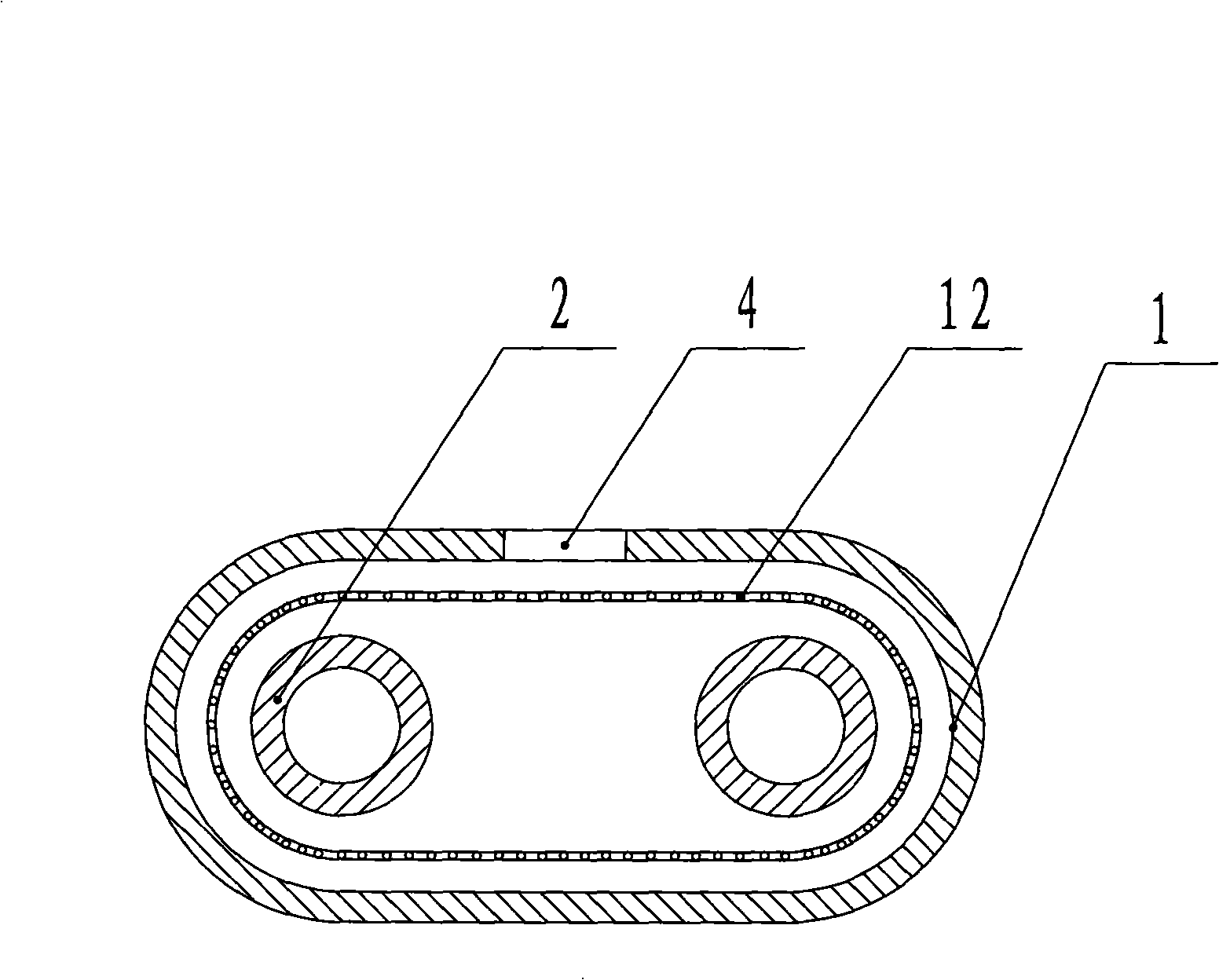

The invention discloses a dual-tower dust removing desulphurization device which comprises a main tower. A flue gas inlet is formed on the main tower, a sprayer is arranged on the top side of the main tower, the upper end of the main tower is sealed, a liquid discharge hole is formed at the lower end, twin towers are inserted to the bottom part in the main tower from the upper end of the main tower and provided with communicating holes to communicate with the main tower, the upper ends of the twin towers communicate with a top tower, a sub-tower sprayer and a sub-tower defogger are arranged in the twin towers, a top tower sprayer and a top tower defogger are arranged in the top tower, and a flue gas outlet is formed on the top tower. The dual-tower dust removing desulphurization device has the following advantages: as the dual-tower dust removing desulphurization device adopts the structure of twin towers, the dual-tower dust removing desulphurization device can carry out the dust removing desulphurization treatment of flue gas emitted by a large-scale coal-fired boiler, the dust removing desulphurization efficiency is high, the coal-fired flue gas after the treatment can achieve the requirements of the environmental protection emission; furthermore, the structure is simple, the operation cost is low and the environmental protection benefits are very good.

Description

Double tower dedusting and desulfurization device technical field The invention relates to a flue gas dust removal and desulfurization device. Background technique my country is a large coal-fired country. Tens of millions of tons of smoke and dust are discharged from various coal-fired boilers every year. These untreated dust-containing and sulfur-containing flue gases are directly discharged into the atmosphere, which is the main cause of air pollution, especially It is the sulfur oxide contained in coal-fired flue gas, which is discharged into the atmosphere and combines with water vapor in the atmosphere to form acid rain, pollute land, water sources, cause serious damage to industry, agriculture and ecological environment, and also endanger people's health . At present, there are several shortcomings in the dust removal and desulfurization devices for coal-fired flue gas at home and abroad: first, the process equipment is complicated and the cost is high; second, the e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D53/78B01D47/06F23J15/04

Inventor 陈汉东魏先勋王继微陈建军张海良李立清石正平

Owner 湘潭市南方高新技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com